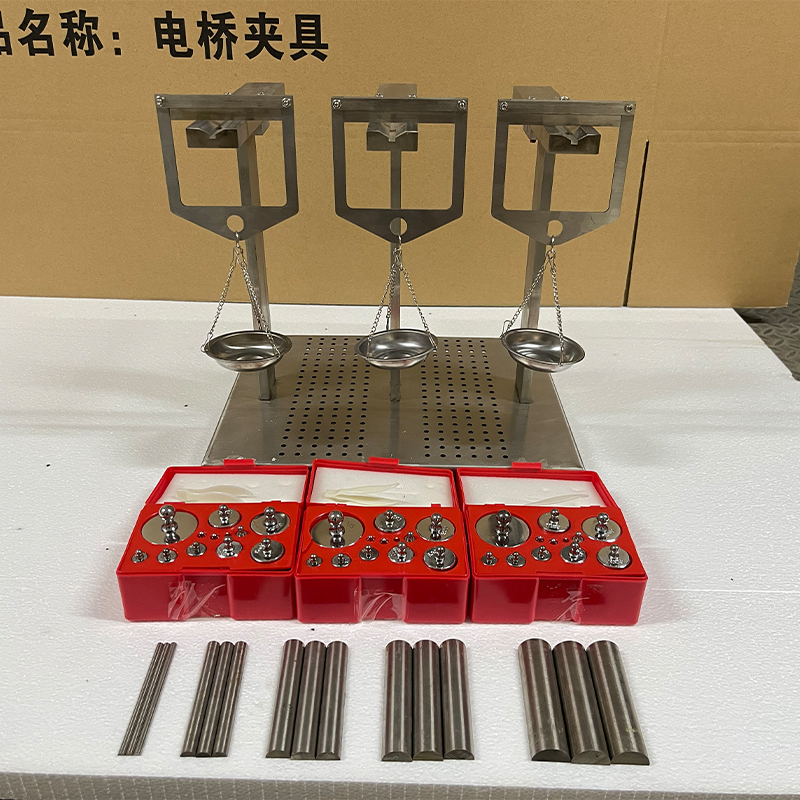

electrical resistivity clamps manufacturer

The Evolution of Electrical Resistivity Clamps A Look into Manufacturers

In the ever-evolving world of electrical engineering, certain tools play a crucial role in ensuring safety, accuracy, and efficiency. Among these tools are electrical resistivity clamps, which have garnered significant attention from manufacturers due to their growing importance in various applications. As energy efficiency and electrical safety become increasingly vital in an array of industries, the demand for high-quality electrical resistivity clamps continues to rise.

Understanding Electrical Resistivity Clamps

Electrical resistivity clamps are specialized tools designed to measure the resistivity of conductive materials. They allow engineers and electricians to assess the electrical properties of materials without the need for extensive modifications, providing a quick and reliable means of obtaining critical data. These clamps function by applying a known voltage across the material and measuring the resulting current, thus enabling users to calculate resistivity based on Ohm's Law.

The ability to accurately measure resistivity is essential for a variety of applications, including grounding system analysis, soil resistivity measurements, and electrical circuit evaluations. Accurate resistivity readings are crucial for the design and installation of efficient grounding systems, which serve to protect lives and equipment from electrical faults.

The Role of Manufacturers

Manufacturers play a vital role in the production of electrical resistivity clamps. The process begins with research and development, where engineers focus on creating designs that enhance the functionality and accuracy of these tools. Advanced materials, miniaturized electronics, and user-friendly interfaces are now common features in modern clamps. Manufacturers strive to balance precision with usability, ensuring that both seasoned professionals and novices can effectively utilize these devices.

Quality assurance is another critical aspect for manufacturers. Given the significant safety implications associated with electrical measurements, ensuring that resistivity clamps meet stringent industry standards is paramount. Reliable manufacturers typically adhere to ISO and IEC standards, providing certification that their products have passed rigorous testing. This commitment to quality not only protects end-users but also bolsters the manufacturer's reputation in a competitive market.

Innovations in Electrical Resistivity Clamps

electrical resistivity clamps manufacturer

Recent years have seen remarkable innovations in resistivity clamp technology. Developments in digital signal processing and wireless connectivity have transformed traditional clamps into sophisticated instruments capable of delivering real-time data to smartphones and tablets. Such advancements enable engineers to conduct field measurements and analyze results on-the-go, vastly improving efficiency.

Moreover, some manufacturers have begun integrating artificial intelligence and machine learning algorithms into their devices. These smart clamps can analyze historical data to predict soil behavior under various conditions, which can be invaluable for engineers designing foundation systems or electrical installations in challenging environments.

Selecting a Manufacturer

With numerous manufacturers in the market, selecting the right one is crucial for ensuring quality and reliability. It is important for buyers to conduct thorough research and consider factors such as the manufacturer's reputation, the quality of materials used, and the technological advancements incorporated into their products. Client testimonials and case studies can offer valuable insights into the performance and reliability of a manufacturer's clamps.

Additionally, good customer support is vital. Engaging with a manufacturer that provides robust technical support and warranties ensures that users can operate the equipment safely and effectively. A reliable manufacturer should also be open to feedback and should continuously improve their products based on user experiences.

Conclusion

As the demand for electrical resistivity clamps continues to grow, manufacturers are at the forefront of innovation and quality assurance. The importance of these tools in ensuring electrical safety and efficiency cannot be overstated. From research and development to incorporating cutting-edge technology, manufacturers are committed to providing high-quality products that meet the evolving needs of electrical professionals.

As industries strive for improved energy efficiency and safety standards, the significance of electrical resistivity clamps will undoubtedly increase, solidifying their role as invaluable tools in the electrical engineering landscape. Therefore, both manufacturers and users must remain vigilant and adaptive to the changing technologies and standards in this dynamic field.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy