Manufacturer of High-Quality Resistor Testers for Accurate Measurements and Performance Testing

The Importance of Resistor Tester Manufacturers in Modern Electronics

In the rapidly evolving world of electronics, precision and reliability are paramount. Among the myriad components that constitute modern circuits, resistors play a fundamental role in managing current flow and ensuring stability. To guarantee the optimal performance of these crucial components, resistor testers have emerged as essential tools for engineers and manufacturers alike. This article delves into the significance of resistor tester manufacturers, exploring their contributions to the electronics industry and the technological advancements defining this niche.

Understanding Resistor Testers

A resistor tester is a specialized device designed to measure the resistance value of resistors, ensuring they operate within specified parameters. These testers can provide direct readings, helping technicians identify faulty components quickly and efficiently. With the proliferation of complex electronic devices—from smartphones to industrial machinery—the demand for precise resistor testing has escalated. This growing need has prompted the rise of dedicated manufacturers focused on producing high-quality resistor testers that meet the rigorous standards set by the industry.

The Role of Manufacturers

Resistor tester manufacturers play a crucial role in the electronic supply chain. They are responsible for designing, producing, and distributing testing equipment that meets various specifications and standards. The best manufacturers invest heavily in research and development to innovate and improve their products continually. By leveraging advancements in technology, they create testers that are not only accurate and reliable but also user-friendly and versatile.

One of the vital contributions of these manufacturers is the development of digital resistor testers, which have largely replaced analog counterparts. Digital testers offer several advantages, including improved accuracy, faster response times, and the ability to store and retrieve measurement data. This feature is particularly beneficial for engineers managing large volumes of components, allowing for efficient testing and documentation.

The Technological Advancements

The competitive landscape of resistor tester manufacturing has driven rapid technological advancements. Manufacturers are now integrating state-of-the-art features such as Bluetooth connectivity, allowing for remote operation and data sharing. This innovation has transformed how engineers conduct tests, enabling them to collect and analyze data on-the-go rather than being tethered to a physical device.

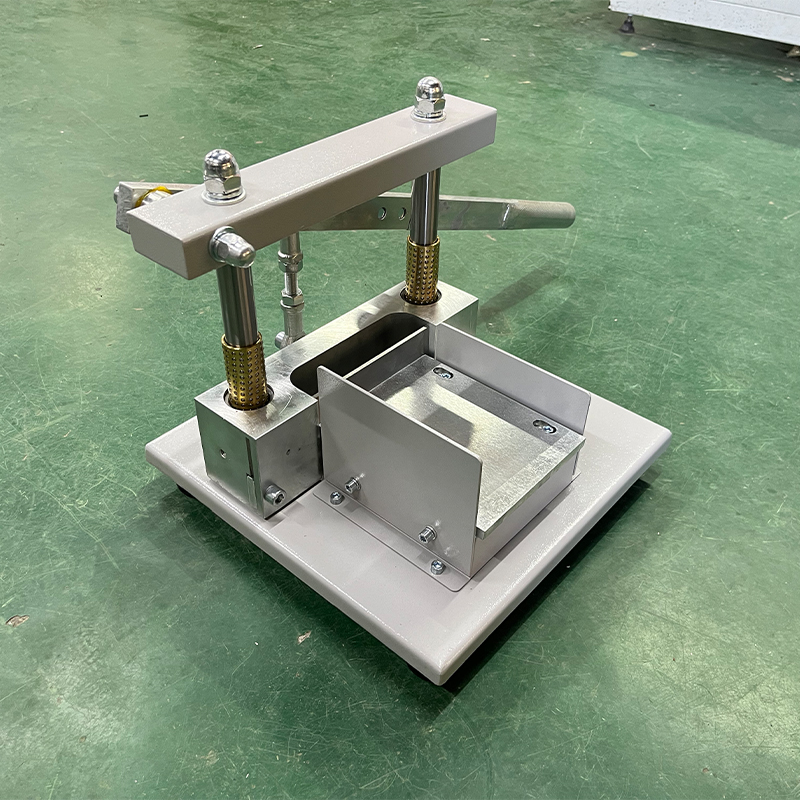

resister tester manufacturer

Moreover, the incorporation of microcontrollers and advanced software algorithms has resulted in testers capable of not only measuring resistance but also assessing component quality with enhanced accuracy. Some modern testers can even identify resistor types, tolerances, and power ratings automatically, reducing the potential for human error.

Quality Assurance and Regulation

Quality assurance is another critical aspect of the manufacturing process for resistor testers. Manufacturers must adhere to international standards and regulations to ensure the reliability of their products. Organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) set guidelines that manufacturers must follow when producing testing equipment. Compliance with these standards assures users that the testing devices are safe, effective, and capable of delivering accurate results.

The Future of Resistor Tester Manufacturing

Looking ahead, the resistor tester manufacturing industry is poised for further evolution. As electronics become increasingly miniaturized and integrated, the testing devices themselves are likely to become more compact and multifunctional. The demand for automated testing solutions will lead to the development of advanced testers capable of performing multiple functions, such as measuring capacitance and inductance alongside resistance.

Additionally, the rise of artificial intelligence and machine learning could revolutionize how resistor testers operate. Future devices may be able to learn from past measurements, improving their analysis capabilities over time and providing more accurate assessments of component health.

Conclusion

In conclusion, resistor tester manufacturers are vital players in the electronics ecosystem. Their innovations and adherence to quality standards ensure that engineers have the tools necessary to maintain the integrity and performance of electronic devices. As technology continues to advance, these manufacturers will play an essential role in shaping the future of electronic testing, ultimately contributing to the reliability and performance of the devices we rely on every day. The journey of resistor testers may be intricate; however, the impact they have on the electronics industry is profound and lasting.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy