tensile strength tester manufacturers exporter

Understanding the Role of Tensile Strength Tester Manufacturers and Exporters

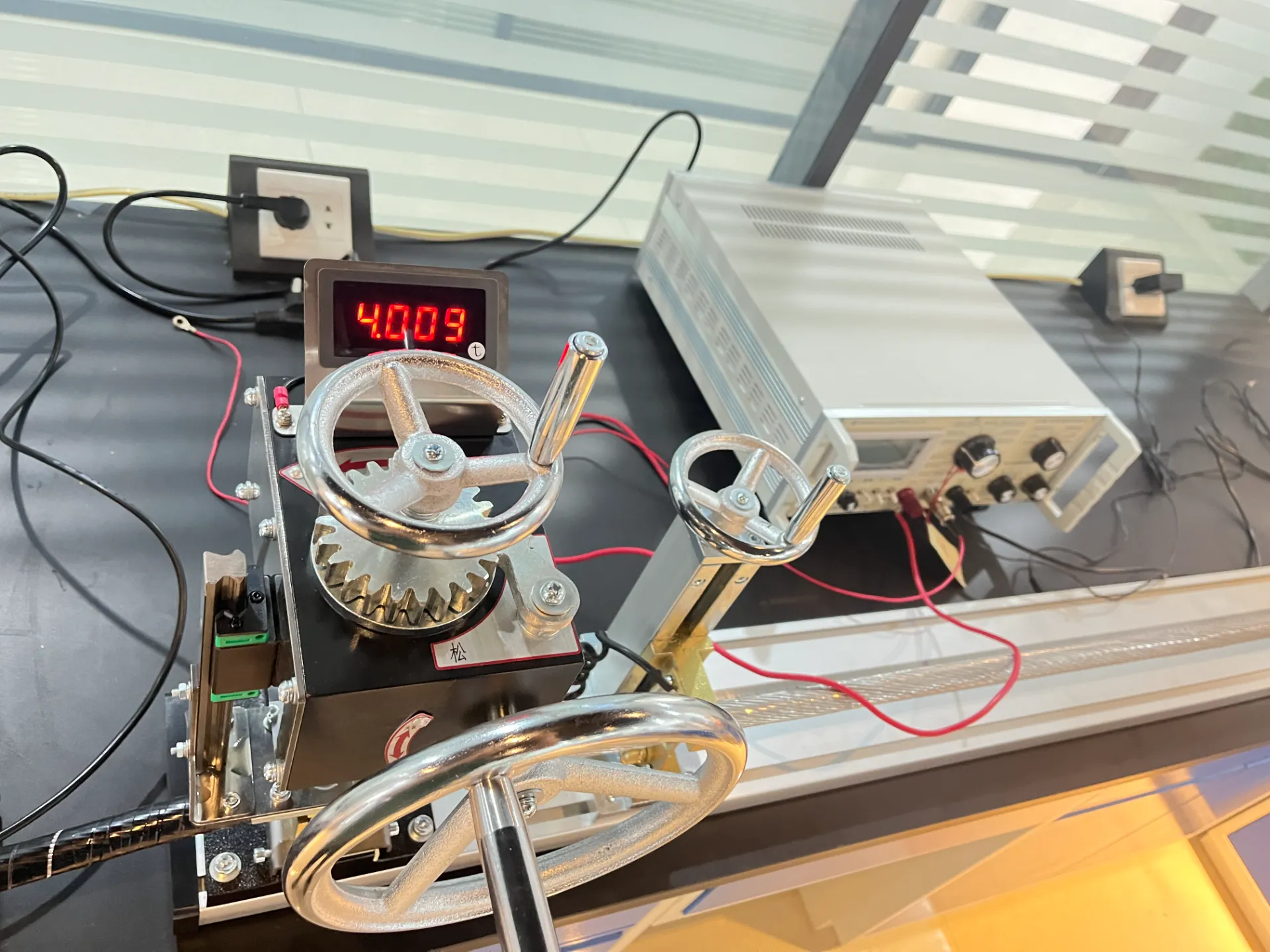

In the realm of material testing, tensile strength testers play a crucial role in determining the strength and durability of materials. These testers measure how much force a material can withstand before failing or breaking, making it essential for manufacturers and quality control professionals across various industries, including construction, automotive, aerospace, and textiles. As the demand for high-quality materials continues to rise globally, the role of tensile strength tester manufacturers and exporters has become increasingly significant.

What is Tensile Strength Testing?

Tensile strength testing involves applying a controlled force to a material sample until it experiences deformation or failure. The primary goal is to measure the maximum load the material can bear while maintaining its structural integrity. Results from these tests provide valuable data on yield strength, ultimate tensile strength, elongation, and reduction of area. Manufacturers use this information to ensure their products meet safety standards and performance specifications.

The Importance of Quality Manufacturers

The quality of tensile strength testers is paramount to obtaining accurate and reliable data. Reputable manufacturers ensure that their equipment complies with international testing standards, such as ASTM and ISO. They invest in advanced technology and engineering practices to develop machines that can perform various tests, including static load tests, dynamic tests, and fatigue tests. High-quality testers are designed for precision, durability, and ease of use, enabling efficient testing procedures that save time and reduce error margins.

Innovation and Technological Advancements

tensile strength tester manufacturers exporter

The field of tensile strength testing is continually evolving, driven by advancements in technology and materials science. Modern tensile strength testers are equipped with sophisticated software that allows for real-time data analysis and reporting, improving the overall testing process. Manufacturers are increasingly incorporating features such as user-friendly interfaces, automatic calibration, and connectivity options for data management. This innovation ensures that engineers and quality control specialists can efficiently interpret results and make informed decisions about material usage.

Global Export Market

As industries become more interconnected through globalization, the demand for tensile strength testers has expanded beyond domestic markets. Manufacturers who export these testing machines contribute to quality assurance in international supply chains. By providing reliable and cutting-edge testing equipment, exporters play a vital role in helping businesses adhere to global quality standards. Countries around the world, especially those with burgeoning manufacturing sectors, rely on high-quality tensile strength testers to ensure their products are competitive in the global marketplace.

Choosing the Right Manufacturer and Exporter

When selecting a tensile strength tester manufacturer or exporter, several factors should be considered. Reputation in the industry, compliance with international standards, after-sales support, and warranty options are crucial elements that influence the decision-making process. Engaging with manufacturers that have a proven track record and positive customer feedback ensures that businesses receive reliable products that meet their specific testing needs.

Conclusion

Tensile strength testers are indispensable tools in the materials testing industry, and the role of manufacturers and exporters is critical in ensuring the availability of high-quality testing equipment. As industries continue to push for superior materials and products, the demand for reliable tensile strength testing will only grow. By focusing on innovation, quality, and customer satisfaction, manufacturers and exporters of tensile strength testers can help shape the future of material testing and contribute to the safety and reliability of products across various sectors. In today’s competitive landscape, investing in quality testing equipment is essential for any company aiming to excel in product development and quality assurance.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy