tensile strength tester manufacturers factory

Understanding the Importance of Tensile Strength Testers in Material Manufacturing

In the rapidly evolving world of manufacturing, the integrity and reliability of materials play a crucial role in determining the quality and safety of end products. Among the myriad of testing equipment available in the industry, tensile strength testers stand out as essential devices for evaluating the strength and ductility of materials. This article explores the significance of tensile strength testers, the manufacturers behind these devices, and the critical role they play in various industrial applications.

What is Tensile Strength Testing?

Tensile strength testing is a fundamental procedure used to assess how materials behave under tension. The process involves subjecting a sample material to a controlled tensile force until it fractures. The key outputs of this test are the ultimate tensile strength (UTS), yield strength, and elongation percentage. These metrics help define the material's performance characteristics, ensuring that they meet the required standards and specifications for specific applications.

The Role of Manufacturers in Tensile Strength Tester Development

The manufacturing of tensile strength testers is a sophisticated process that requires precision engineering and an understanding of material science. Reputable manufacturers invest heavily in research and development to innovate and enhance their testing equipment. They utilize advanced technologies and materials to create machines that can provide accurate, reproducible, and reliable data.

Leading manufacturers of tensile strength testers often offer a range of models tailored to various testing needs, from basic mechanical systems to fully automated electronic machines. Companies specializing in these devices frequently collaborate with industry experts to ensure their equipment meets global standards and regulatory requirements.

Key Features of Tensile Strength Testers

1. Precision Control Modern tensile strength testers are equipped with sophisticated software and hardware that allow for precise control over the testing process. This includes the ability to set specific testing speeds, environmental conditions, and data recording parameters.

tensile strength tester manufacturers factory

2. Versatile Testing Capabilities High-quality tensile strength testers can accommodate a wide variety of materials, including metals, plastics, textiles, and composites. This versatility is crucial for manufacturers that deal with diverse product lines.

3. Data Management Systems The ability to collect, manage, and analyze data is a significant advantage of contemporary tensile strength testers. Many manufacturers integrate data logging software that helps in generating detailed reports, enabling users to track material performance over time.

4. User-Friendly Interfaces The latest testers often come equipped with intuitive user interfaces, making them easier for operators to use. Touchscreen controls, predefined testing protocols, and easy-to-read display screens contribute to seamless operation.

Applications Across Industries

Tensile strength testers find applications across various industries, including aerospace, automotive, construction, and textiles. In the automotive industry, for example, the strength and durability of components are paramount; tensile testing ensures that materials used in vehicles can withstand the stresses encountered during operation. Similarly, in the aerospace sector, materials must meet strict safety standards, making tensile strength testing indispensable for quality assurance.

The construction industry relies heavily on tensile strength testing to evaluate the properties of steel rebar, concrete, and other structural materials. This testing process informs engineers and architects about the load-bearing capabilities of materials, directly impacting safety and structural integrity.

Conclusion

As manufacturing technology continues to advance, the significance of tensile strength testers cannot be overstated. These devices serve as the backbone of material testing, providing essential data that informs material selection and quality assurance processes. Manufacturers who specialize in tensile strength testers play a vital role in ensuring that the equipment is reliable, accurate, and equipped with the latest technologies.

In an era where safety and reliability are paramount, investing in high-quality tensile strength testers is essential for any manufacturer aiming to uphold industry standards and deliver top-tier products. By understanding the capabilities of these machines and the importance of proper testing, manufacturers can ensure the longevity and durability of their materials, ultimately contributing to the overall success of their operations.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

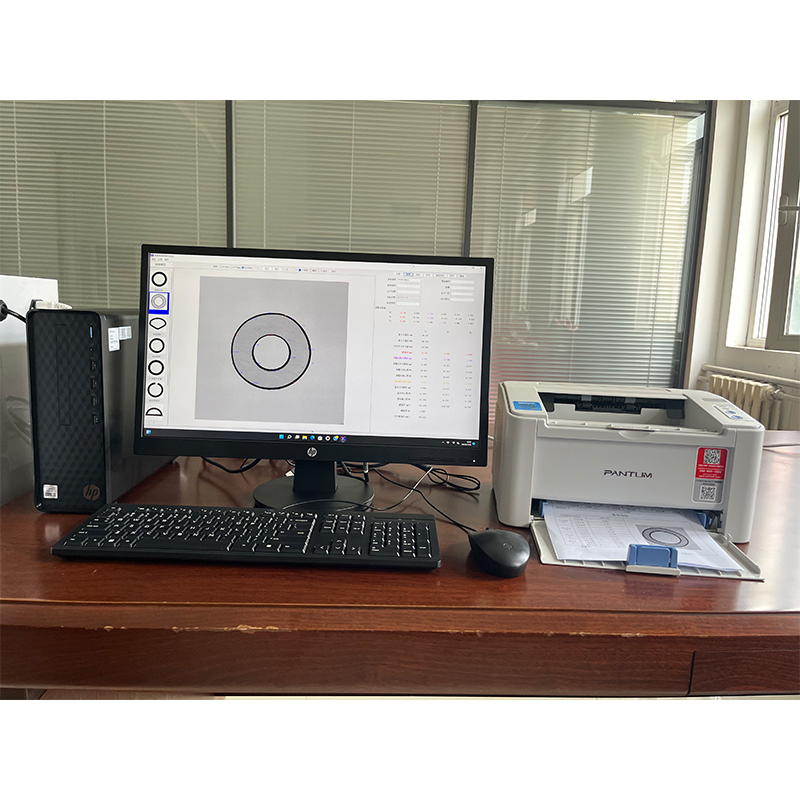

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy