Tensile Testing Machines for Measuring Material Break Strength and Performance

Understanding the Importance of Tensile Testing for Break Strength Evaluation

Tensile testing is a fundamental method used to determine the mechanical properties of materials, especially in applications where understanding the strength and durability of materials is critical. This testing technique is particularly important for manufacturers and engineers in various industries, including textiles, plastics, metals, and construction. Companies specializing in tensile testing equipment, such as tensile testers for break strength, play a crucial role in delivering accurate and reliable assessments that inform product development and quality control.

At its core, tensile testing involves applying a uniaxial force to a material specimen and measuring its response until it breaks. This process provides essential data on several key mechanical properties, including yield strength, ultimate tensile strength, elongation, and modulus of elasticity. The tensile tester, typically equipped with advanced technology, ensures precise measurements that are vital for assessing a material's performance in real-world applications.

Understanding the Importance of Tensile Testing for Break Strength Evaluation

Tensile testing for break strength also plays a critical role in compliance with industry standards and regulations. Many sectors have specific guidelines governing the mechanical properties of materials used in products. By utilizing high-quality tensile testers, companies can ensure that their materials meet these stringent requirements, avoiding costly recalls and enhancing their reputation for quality and safety.

tensile tester for break strength company

The reliability of a tensile testing setup is paramount. Companies offering tensile testers for break strength need to focus on several factors that contribute to the accuracy and precision of their equipment. Calibration is one of them; a regularly calibrated tensile tester ensures that the results are reproducible and consistent. Furthermore, the testing environment should be controlled to prevent external factors, such as temperature and humidity, from influencing the outcome.

Moreover, advancements in technology have significantly upgraded the capabilities of tensile testers. Modern systems often come equipped with computer-based software that allows users to analyze data in real-time. This software can generate detailed reports and graphs that facilitate a better understanding of material performance. Such advancements not only enhance operational efficiency but also enable organizations to make data-driven decisions regarding material use and production processes.

Moving beyond the laboratory applications, the relevance of tensile testing for break strength extends into the marketplace. Consumers are more informed and concerned about the materials used in products they buy. They demand transparency regarding product safety and durability. Companies that invest in comprehensive testing protocols can market their products with confidence, guaranteeing the reliability and robustness of their offerings. This not only helps in building consumer trust but also provides a competitive edge in increasingly saturated markets.

In conclusion, the role of tensile testers for break strength evaluation cannot be overstated. As industries evolve and the demand for high-quality materials increases, the necessity for precise and reliable testing methods becomes ever more critical. Companies that specialize in tensile testing equip engineers and manufacturers with the tools needed to ensure that their products meet safety regulations, perform effectively under stress, and satisfy consumer expectations. The ongoing advancements in testing technology and methodologies promise to further enhance this vital aspect of material science, shaping the future of product development across multiple sectors. As such, investing in sophisticated tensile testing equipment is not merely a technical necessity but a strategic imperative for any organization aiming to thrive in today’s quality-conscious market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

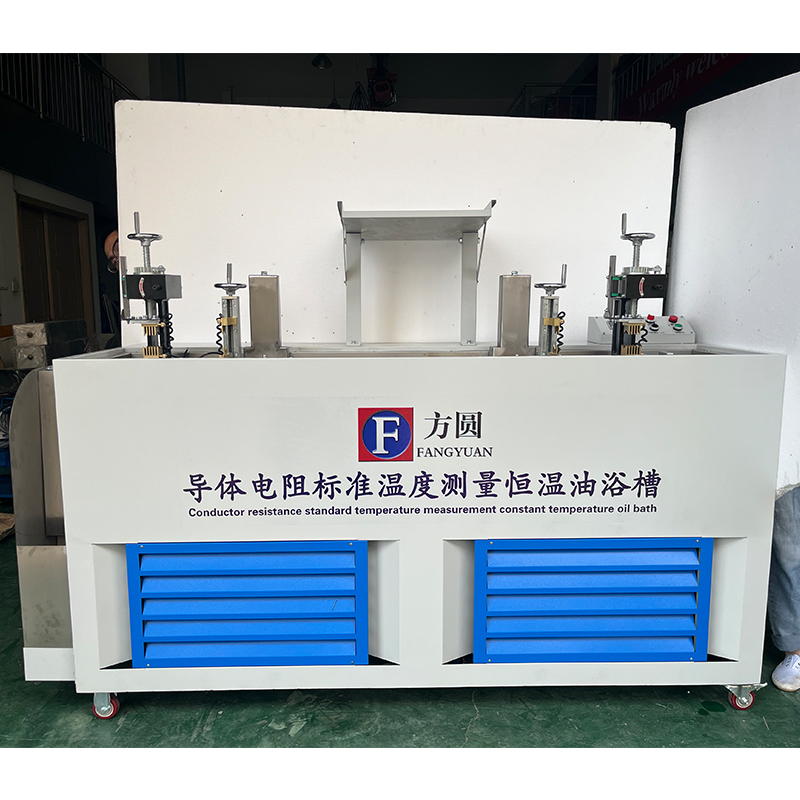

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy