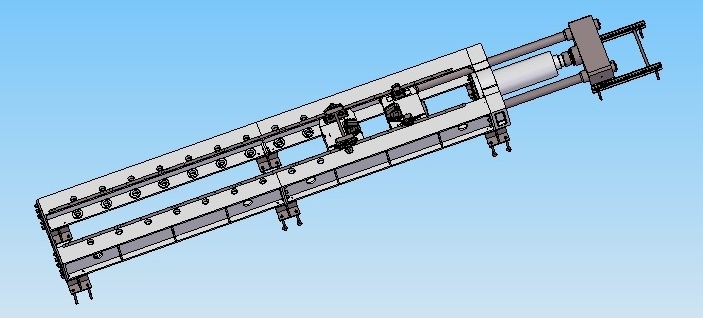

underground coaxial cable slicer factory

The Importance of Underground Coaxial Cable Slicers A Look into the Factory Production Process

In the modern world, efficient communication and data transfer are pivotal to our daily lives, largely facilitated by various types of cables. Among these, coaxial cables, known for their robustness and high-frequency transmission capabilities, have become indispensable in telecommunications and television services. However, the installation and maintenance of these cables require specialized tools, one of which is the underground coaxial cable slicer. This article explores the significance of these tools and provides insight into their production in factories.

Coaxial cables, designed with a central conductor encased in an insulating layer, a metallic shield, and an outer jacket, offer advantages such as reduced electromagnetic interference and increased durability. When these cables are installed underground, they must be sliced or cut with precision to prevent damage that could disrupt services. This is where the underground coaxial cable slicer comes into play.

The underground coaxial cable slicer is engineered to provide exact cuts that maintain the integrity of the cable. It is equipped with sharp blades and a robust design to handle tough conditions often found underground—like soil, moisture, and varying temperatures. These features are essential for ensuring that the cables can be efficiently serviced or connected without compromising their functionality.

In a factory setting, the production of underground coaxial cable slicers involves a meticulous process. It typically starts with the selection of raw materials, which must be durable and resistant to corrosion. Common materials include high-quality steel for the blades and durable plastics or metals for the handles and body housing. The choice of materials is crucial, as the slicers must withstand the rigors of underground operations.

underground coaxial cable slicer factory

Once materials are selected, the next phase is manufacturing. Advanced machinery is employed to cut, shape, and assemble the components of the slicer. Precision is key; even the slightest deviation can affect the tool’s performance. Factories often utilize computer numerical control (CNC) machines to ensure each part is produced to exact specifications. This technology guarantees high levels of uniformity and quality in the finished products.

Following the manufacturing stage, the slicers undergo rigorous testing to ensure they meet safety and efficiency standards. Testing involves simulating real-world conditions to assess the tool’s performance and durability. Only those that pass these tests are approved for distribution. This quality control process is vital, as it ensures that contractors and technicians using the slicers can perform their jobs without encountering equipment failure.

After quality assurance, the tools are packaged and shipped to various suppliers and wholesalers. This distribution network plays a significant role in making the tools accessible to contractors who specialize in underground installations. By providing easy access to reliable tools, manufacturers support the installation and maintenance of coaxial cables, ultimately contributing to the smooth operation of communication networks and services.

In conclusion, underground coaxial cable slicers play a crucial role in the telecommunications industry. Their careful design and production process in factories ensure that they can handle the challenges of underground work while providing precision and reliability. As technology continues to advance, the manufacturing processes for these tools will likely become more sophisticated, further enhancing their performance and efficiency. As we rely more and more on uninterrupted communication, the importance of high-quality tools like underground coaxial cable slicers cannot be overstated. They are critical to maintaining the backbone of our modern digital infrastructure.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy