china conductor resistance constant temperature test

Understanding China’s Conductor Resistance Constant Temperature Test

In the realm of electrical engineering and materials science, the measurement of conductor resistance is a fundamental aspect that determines the efficiency and performance of electrical systems. As China strives to enhance its technological advancements and infrastructure, the significance of conducting a constant temperature test for conductor resistance has become increasingly important. This article explores the principles and processes involved in the constant temperature resistance test and its implications for the electrical industry in China.

What is Conductor Resistance?

Conductor resistance refers to the resistance encountered by electric current as it flows through a conductor. This resistance is a crucial factor as it influences the amount of power lost in the form of heat due to the inherent properties of the materials used. In practical applications, high resistance can lead to inefficiencies and potential failures in electrical systems. Therefore, assessing the resistance of conductors under stable conditions is vital for ensuring reliable performance.

The Constant Temperature Test

A constant temperature test is a standardized method used to measure the resistance of conductors under controlled thermal conditions. This is essential because the resistance of materials can vary significantly with temperature changes. By maintaining a constant temperature during the test, engineers can obtain accurate and consistent measurements that reflect the conductor's inherent properties rather than transient thermal effects.

Procedure of the Test

The process of conducting a constant temperature resistance test typically involves the following steps

1. Preparation of Samples Select the conductor materials to be tested. This may include copper, aluminum, or other alloys commonly used in electrical applications.

2. Temperature Stabilization The test environment must be controlled to ensure that the temperature remains constant throughout the testing process. This could involve using temperature-controlled chambers or environments with precise heating and cooling mechanisms.

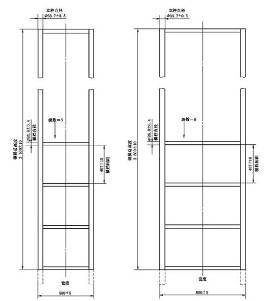

3. Measurement Setup Utilize a four-wire measurement technique, which involves using two wires to supply current and two separate wires to measure voltage. This methodology eliminates the impact of lead resistance, providing a more accurate resistance reading.

china conductor resistance constant temperature test

4. Data Collection Once the setup is complete and the temperature stabilized, the current is applied, and the voltage drop across the conductor is measured. This data is used to calculate the resistance using Ohm's Law (R = V/I).

5. Analysis Analyze the collected data, focusing on how the resistance correlates with the material properties and the temperature.

Importance of the Test in China

The continuous development of China's electrical and electronics industry necessitates reliable and efficient components. The constant temperature test for conductor resistance is crucial for several reasons

1. Quality Assurance By ensuring accurate resistance measurements, manufacturers can maintain high standards for their products, leading to enhanced performance and customer satisfaction.

2. Material Development Engineers and researchers can use the data obtained from these tests to innovate and develop new materials with lower resistance, contributing to the advancement of technologies like renewable energy systems and electric vehicles.

3. Regulatory Compliance Many electrical standards and regulations require thorough testing of materials used in power transmission and distribution. The constant temperature test ensures compliance with these standards, promoting safety and reliability in electrical systems.

4. Efficiency Improvement By understanding the resistance behavior of conductors at different temperatures, industries can design better systems that minimize energy loss, thereby improving overall efficiency.

Conclusion

The conductor resistance constant temperature test plays a pivotal role in the advancement of electrical engineering practices in China. By facilitating the accurate measurement of conductor resistance under controlled conditions, this testing method not only ensures the quality and efficiency of electrical components but also supports innovation and compliance with industry standards. As China continues to invest in its electrical infrastructure and technology, the importance of rigorous testing methods like the constant temperature resistance test will only grow, paving the way for a more efficient and reliable electrical future.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy