Digital Optical Profile Projectors Manufacturing Facility Overview and Capabilities

The Rise of Digital Optical Profile Projectors in Modern Manufacturing

In an age where precision engineering and advanced technology dominate the manufacturing landscape, digital optical profile projectors have emerged as essential tools for ensuring accuracy and quality in various industries. These sophisticated instruments provide manufacturers with the ability to measure and inspect complex parts with unmatched precision, making them indispensable for companies that rely on tight tolerances and intricate designs. This article explores the significance of digital optical profile projectors, their working principles, benefits, and the future of this technology in manufacturing.

Understanding Digital Optical Profile Projectors

Digital optical profile projectors are advanced measuring devices that project the silhouette of a part onto a screen, allowing operators to inspect and measure its dimensions against predefined geometries. Unlike traditional profile projectors that rely on analog technology, digital versions harness the power of digital imaging and computer processing to enhance measurement accuracy and provide real-time data analysis.

Working Principles

At the heart of a digital optical profile projector is its optical system. It typically comprises a high-intensity light source, lenses, mirrors, and a digital camera. The process begins by placing the workpiece on a stage under the projector. The instrument illuminates the object, and its silhouette is projected onto a flat surface. The digital camera captures this image, which is then processed using specialized software.

The digital software enables operators to measure various dimensions of the projected image, including angles, radii, and distances, with high precision. Measurements can be displayed in real-time and compared against CAD models or predefined standards, streamlining quality assurance processes.

Benefits of Digital Optical Profile Projectors

1. Enhanced Precision The transition from analog to digital technology in profile projectors significantly improves measurement accuracy. The digital imaging system eliminates many of the errors associated with manual measurements, ensuring that components meet stringent quality standards.

digital optical profile projectors factory

2. Time Efficiency Digital optical profile projectors expedite the inspection process. With automated features and quick data analysis, manufacturers can reduce downtime and improve throughput without compromising quality.

3. User-Friendly Interface Modern digital profile projectors come equipped with intuitive software that simplifies the measurement process. Operators can easily navigate through functionalities, making it accessible even for personnel with limited technical backgrounds.

4. Versatility These devices can measure a wide range of components, from simple geometric shapes to complex automotive and aerospace parts. This versatility allows manufacturers to consolidate their measurement equipment, reducing costs and saving space in the production area.

5. Documentation and Traceability Digital optical profile projectors facilitate detailed record-keeping of measurements. This is crucial for quality control and compliance with industry standards, as it provides verifiable data for audits and inspections.

Future Trends and Innovations

As technology continues to evolve, the digital optical profile projector sector is poised for significant advancements. Emerging trends include the integration of artificial intelligence (AI) and machine learning into measurement processes. These technologies can analyze measurement data to detect patterns, predict failures, and improve manufacturing processes.

Additionally, the development of more advanced optics and sensors will enhance the capabilities of digital optical profile projectors, allowing for even finer measurement resolutions and the ability to inspect more complex geometries.

Conclusion

Digital optical profile projectors represent a pivotal advancement in the field of metrology and quality assurance in manufacturing. Their ability to provide accurate, fast, and reliable measurements makes them indispensable in various industries, including aerospace, automotive, and medical device manufacturing. As innovations continue to unfold, these instruments will likely play an even more significant role in the quest for precision and efficiency in manufacturing processes. Companies that adopt this technology will be better positioned to meet the increasingly demanding standards of the modern market, ensuring their competitiveness in an ever-evolving landscape. As we look to the future, the integration of digital optical profile projectors with other advanced technologies promises to further enhance their capabilities, driving the next wave of manufacturing excellence.

-

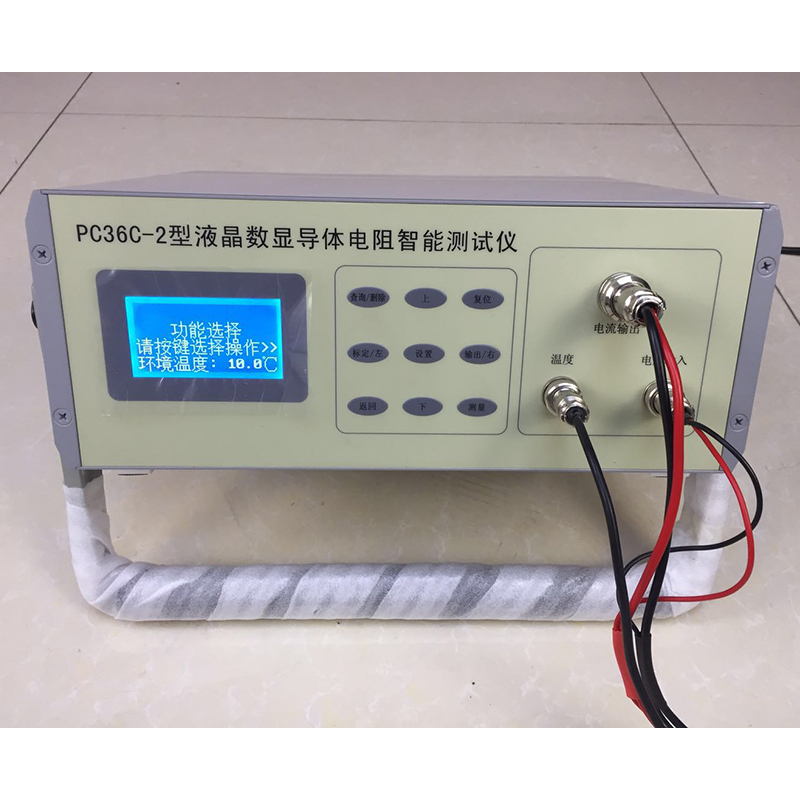

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy