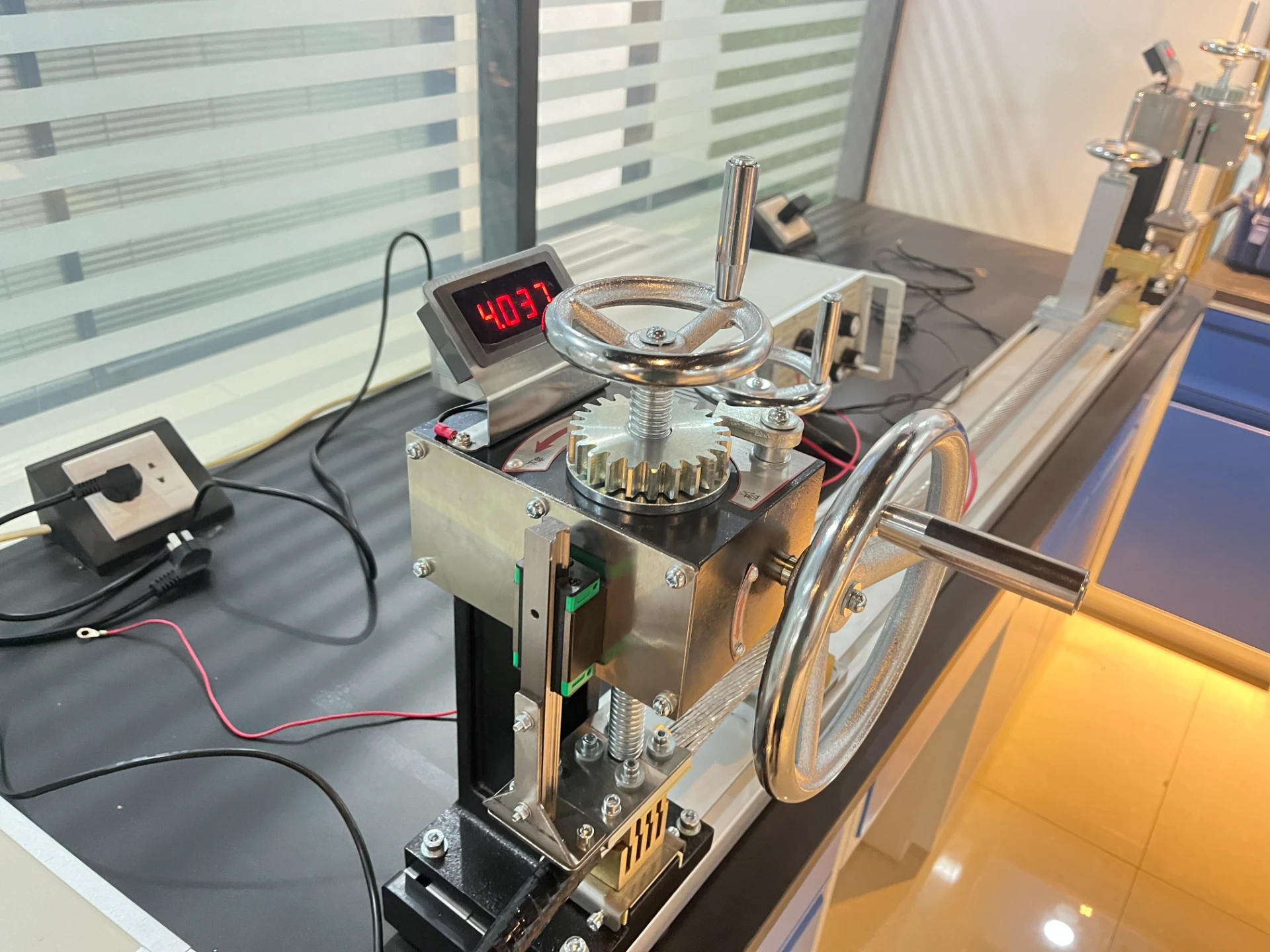

resistance fixture

Understanding the Importance of Resistance Fixture in Electrical Engineering

In the field of electrical engineering, the concept of resistance fixtures plays a critical role, particularly in the testing and measurement of electrical components. Resistance fixtures provide a controlled environment to assess how electrical devices respond to different resistance levels, thereby ensuring their functionality, safety, and reliability in real-world applications. This article delves into the significance of resistance fixtures, their typical design and application, and the technological advancements that have enhanced their use.

At its core, a resistance fixture is a specialized device designed to create a known resistance in a circuit. This is vital for various testing scenarios, especially when analyzing how particular components, such as resistors, capacitors, and integrated circuits, behave under specific loads or conditions. By providing a standard resistance, engineers can calibrate their instruments, validate circuit designs, and perform quality assurance on their products.

One of the main advantages of using resistance fixtures is their ability to simulate a wide range of conditions. For example, in the automotive industry, resistance fixtures are utilized to test electronic components found in vehicles. By mimicking the various resistive loads these components may encounter during operation, engineers can ensure that the devices will function correctly when integrated into the final product. Similarly, in the telecommunications sector, resistance fixtures help evaluate the performance and reliability of components used in network infrastructure.

The design of resistance fixtures can vary widely, depending on the specific requirements of the testing process. Typically, these fixtures consist of resistive elements that can be adjusted or calibrated to provide different levels of resistance. Advanced fixtures may incorporate digital interfaces that enable precise control over resistance levels and allow for automated testing procedures. This automation is particularly valuable in high-volume production environments where consistency and efficiency are paramount.

resistance fixture

Moreover, the evolution of technology has led to the introduction of more sophisticated resistance fixtures that can offer not just resistive loads, but also dynamic testing capabilities. For instance, some modern fixtures can simulate transient conditions, allowing engineers to observe how devices react to sudden changes in load or voltage. This capability is crucial, as it provides a more comprehensive understanding of a component's performance in real-life situations.

In addition to facilitating comprehensive testing, resistance fixtures contribute significantly to safety in the electrical domain. By ensuring that components are thoroughly tested against specified resistance benchmarks, manufacturers can avoid costly recalls and safety hazards that may arise from faulty devices. Reliability testing, therefore, becomes an essential part of the design process, with resistance fixtures serving as vital tools in this endeavor.

When it comes to software integration, modern resistance fixtures can be connected to testing software that analyzes the data collected during measurement. This integration allows for real-time monitoring and evaluation of performance, providing engineers with immediate feedback and facilitating rapid decision-making. The use of data analytics in conjunction with resistance testing enhances the overall quality of electrical components, ultimately benefiting consumers and industries alike.

In conclusion, resistance fixtures are indispensable in the realm of electrical engineering, providing the means to accurately measure and evaluate the performance of various components under controlled resistive conditions. As technology continues to advance, the capabilities and applications of resistance fixtures are only expected to expand, supporting the ongoing development of sophisticated and reliable electrical devices. Whether in automotive, telecommunications, or consumer electronics, the relevance of resistance testing remains significant, emphasizing the importance of these fixtures in ensuring the seamless operation of electrical systems worldwide.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy