Factory for Measuring Resistance with Advanced Technology and Precision Instruments

Exploring the World of Resistance Measurement Machine Factories

In the realm of industrial technology and electrical engineering, resistance measurement plays a pivotal role. Resistance measurement machines, or ohmmeters, are essential tools for determining the electrical resistance of various materials and components. With the increasing demand for precise and reliable measurement devices, factories specializing in the production of resistance measurement machines are becoming increasingly significant. This article delves into the essential aspects of these factories, focusing on their technology, production processes, and market trends.

The Importance of Resistance Measurement

Resistance measurement is fundamental in various applications, from quality control in manufacturing to testing in research and development. Accurate resistance readings are crucial for ensuring the functionality of electronic components, diagnosing issues in circuits, and maintaining the integrity of electrical systems. With advancements in technology, the scope of resistance measurement has expanded, making it a vital component in industries such as telecommunications, automotive, and consumer electronics.

State-of-the-Art Technology

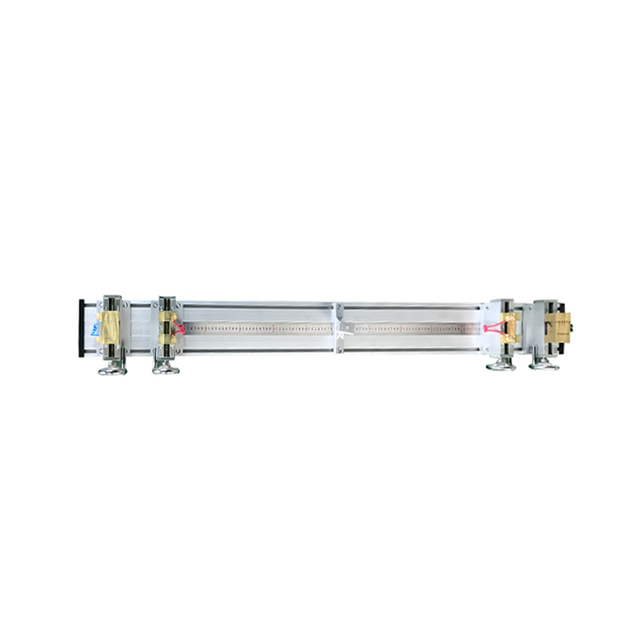

Resistance measurement machine factories leverage cutting-edge technology to produce high-quality measurement devices. These machines often feature advanced circuits, precision resistors, and digital interfaces that ensure accurate readings and ease of use. Moreover, manufacturers are increasingly incorporating automation and smart technology into their production processes. This not only boosts efficiency but also enhances the consistency and quality of the machines produced.

For instance, modern resistance measurement machines may include microcontrollers that enable automatic calibration, temperature compensation, and data logging functionalities. These features are particularly beneficial for users who require high precision and reliability in measurements. Additionally, significant research and development investments are leading to the introduction of new technologies, such as connected devices that allow for remote monitoring and control.

Production Processes in Resistance Measurement Machine Factories

The production of resistance measurement machines involves several stages, including design, prototyping, assembly, and quality assurance

. Each stage is critical to ensuring that the final product meets industry standards and customer expectations.resistance measurement machine factory

1. Design and Prototyping The design phase involves collaboration between engineers and designers to create a machine that is not only functional but also user-friendly. Prototyping allows for testing and refinement before mass production begins.

2. Assembly The assembly process may vary depending on the complexity of the machine. Automated assembly lines are common in larger factories, ensuring precision and reducing the potential for human error. In contrast, smaller manufacturers might rely on skilled technicians for intricate assemblies.

3. Quality Assurance Rigorous testing is vital in the production of resistance measurement machines. Factories often employ various testing methods to ensure accuracy, durability, and compliance with international standards. This could include temperature cycling tests, vibration tests, and extensive calibration checks.

Market Trends and Challenges

The market for resistance measurement machines is witnessing robust growth, driven by the increasing demand for reliable electrical testing equipment across various sectors. However, this growth is accompanied by challenges. For instance, the rapid pace of technological advancements requires manufacturers to continuously innovate and update their product lines. Additionally, competition from global players can pressure prices and profit margins.

Moreover, the sustainability trend is influencing manufacturing practices, with many factories exploring eco-friendly materials and production methods. This shift not only helps in reducing the carbon footprint but also appeals to a growing segment of environmentally conscious consumers.

Conclusion

As technology continues to evolve, resistance measurement machine factories are at the forefront of innovation in the field of electrical measurement. With an unwavering commitment to quality and precision, these factories are vital in supporting industries that rely on accurate resistance measurements. Through advanced technologies and efficient production processes, they are poised to meet the growing demand for high-quality measurement equipment, ensuring that the future of electrical engineering is bright and efficient. As we move forward, the role of these factories will undoubtedly continue to grow, shaping the way we understand and measure electrical resistance in countless applications.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy