fire resistance test equipment manufacturers

The Importance of Fire Resistance Test Equipment in Safety Standards

Fire safety is a critical concern for industries ranging from construction to manufacturing. Ensuring that materials used in various applications can withstand fire and prevent its spread is essential for life safety, property protection, and environmental stewardship. This is where fire resistance test equipment comes into play. Fire resistance test equipment manufacturers play a pivotal role in providing the tools necessary to assess and certify the fire performance of building materials and systems.

Understanding Fire Resistance Testing

Fire resistance testing evaluates how long a material or assembly can withstand fire exposure while maintaining its structural integrity and thermal insulation. The tests are usually governed by standardized methods, such as those established by ASTM International or the National Fire Protection Association (NFPA) in the United States. These tests often include elements like the temperature rise of the unexposed side of a material, structural stability, and integrity under extreme heat.

The results from these tests provide valuable information that governs building codes and regulations. Fire-resistant materials are crucial not only for structural integrity but also for the safety of occupants in a building during a fire emergency. Consequently, the effectiveness of fire resistance testing directly affects public safety and compliance with legal safety standards.

Role of Manufacturers in Fire Resistance Testing

Fire resistance test equipment manufacturers provide a range of products designed specifically for testing the fire performance of materials. This includes furnaces, calorimeters, thermocouples, and sophisticated data acquisition systems that allow for real-time monitoring and assessment during testing. These devices are crucial in providing accurate data that can influence safety certifications and insurance requirements.

1. Quality Assurance Manufacturers of fire resistance testing equipment ensure that their products meet the necessary quality and regulatory standards. They develop state-of-the-art technology that aligns with the latest advancements in material science, enabling more precise and reliable testing results.

fire resistance test equipment manufacturers

2. Innovation The field of fire resistance is ever-evolving. Manufacturers invest in research and development to improve testing methods and equipment. Innovations such as automated testing systems and enhanced data analytics capabilities allow for faster results and more detailed analysis, which can lead to better fire safety solutions.

3. Customization Different industries have varying requirements for fire resistance testing. Manufacturers often provide customized equipment and solutions tailored to specific material characteristics or testing protocols. This adaptability ensures that all relevant variables are accounted for in the testing process.

The Impact of Fire Resistance Test Equipment on Industries

The proper use of fire resistance test equipment has a profound impact on various sectors. In construction, for example, architects and engineers depend on accurate test data to select materials that comply with fire safety codes. In the aerospace and automotive industries, manufacturers must ensure their products can withstand extreme conditions, including high heat from fire exposure.

Furthermore, the insurance industry often relies on documentation provided by manufacturers of fire resistance test equipment to assess risk and determine policy regulations. Without rigorous testing and validation, the potential for catastrophic failures rises, resulting in increased liability and insurance costs.

Conclusion

In conclusion, fire resistance test equipment manufacturers play a critical role in supporting fire safety across multiple industries. Their commitment to innovation, quality assurance, and customization directly impacts how businesses approach material selection and safety compliance. As the industry continues to evolve and new materials are developed, the importance of reliable fire resistance testing will only increase. Investing in advanced testing equipment and trusting in experienced manufacturers is essential for ensuring safety in an unpredictable environment where fire can have devastating consequences. The collaboration between manufacturers and industries ultimately fosters a safer future for all.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

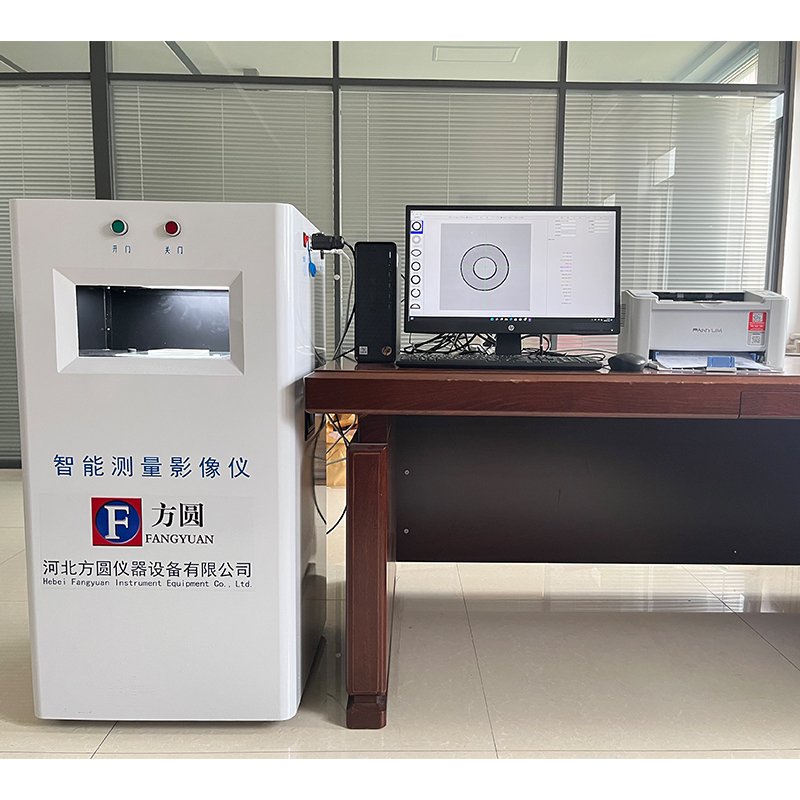

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy