DQ-I Fine Wire Conductor Resistance Fixture: High Precision

The Imperative of Precision in Fine Wire Conductor Resistance Testing

In the rapidly evolving landscape of electronics, automotive, and telecommunications, the performance and reliability of fine wire conductors are paramount. Electrical conductivity, directly linked to resistance, dictates efficiency, signal integrity, and overall product lifespan. Accurate resistance measurement is not merely a quality control step; it is a fundamental aspect of material science and engineering. Specialized tooling, such as the DQ-I Fine Wire Conductor Resistance Fixture, plays a pivotal role in ensuring that ultra-fine wires, often less than 0.1 mm in diameter, meet stringent industry specifications. This fixture provides the necessary stability, contact precision, and insulation to perform highly accurate resistance measurements, minimizing measurement uncertainties and ensuring compliance with international standards like ASTM B193.

Industry Trends Driving Demand for Advanced Resistance Fixtures

The increasing miniaturization of electronic components, the advent of high-frequency data transmission, and the push for higher energy efficiency are creating unprecedented demands for advanced materials and ultra-precise measurement tools. In industries ranging from aerospace and medical devices to consumer electronics, fine wires are becoming thinner while conductivity requirements are becoming stricter. This trend necessitates testing equipment that can handle extremely delicate samples without compromising measurement accuracy. The rise of IoT (Internet of Things) devices, electric vehicles, and advanced robotics further accelerates this demand, as these technologies rely heavily on complex wiring harnesses and highly conductive, miniature components. Robust, repeatable, and reliable measurement fixtures are no longer a luxury but a critical necessity for maintaining competitive edge and ensuring product safety and performance in these high-stakes applications.

Understanding the DQ-I Fine Wire Conductor Resistance Fixture: Technical Parameters

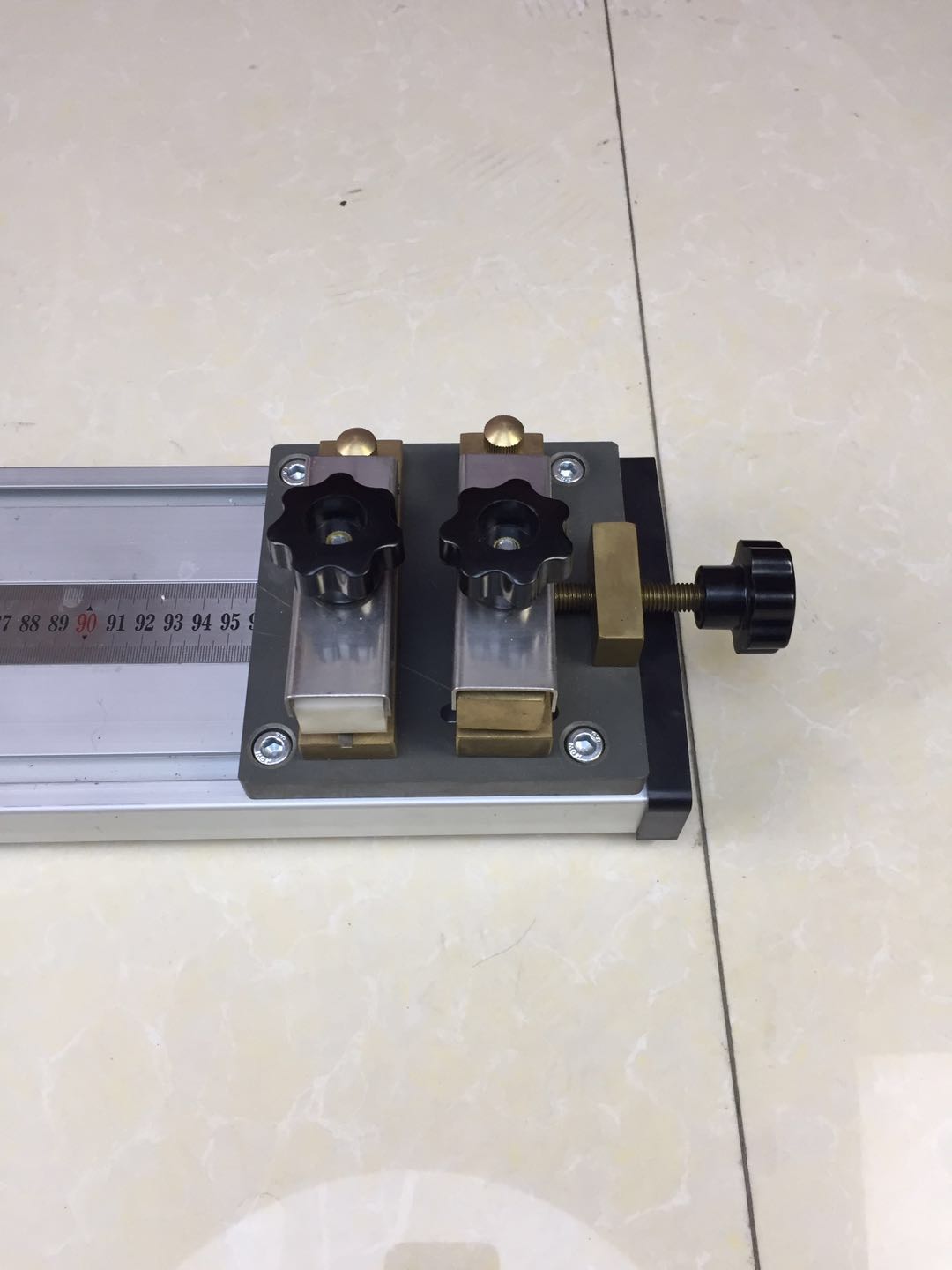

The DQ-I Fine Wire Conductor Resistance Fixture is engineered for precision and reliability, utilizing the industry-standard four-wire Kelvin method to eliminate contact resistance errors, which are particularly significant when measuring very low resistances or thin conductors. Its design focuses on ensuring stable and repeatable contact with delicate fine wires, a critical factor for accurate data. The fixture accommodates a broad range of wire diameters and lengths, making it versatile for various testing requirements. Its construction materials are carefully selected for their electrical insulation properties, mechanical stability, and durability, ensuring a long service life and consistent performance even under rigorous industrial use. Key technical specifications are outlined below:

| Parameter | Specification | Notes |

|---|---|---|

| Measurement Method | Four-wire Kelvin method | Minimizes lead and contact resistance errors. |

| Applicable Wire Diameter Range | 0.01 mm to 1.0 mm (AWG 58 to AWG 18) | Adjustable clamping mechanism. |

| Standard Measurement Lengths | Selectable from 100 mm, 200 mm, 300 mm | Ensures standardized testing. |

| Fixture Material | Precision-machined anodized aluminum, insulating ceramics, gold-plated contacts | Ensures stability, durability, and low contact resistance. |

| Repeatability | Typically | Critical for quality assurance and R&D. |

| Operating Temperature | 0°C to 50°C (32°F to 122°F) | Standard laboratory conditions. |

| Compliance Standards | Meets or exceeds ASTM B193, IEC 60317 | Ensures global acceptance of test results. |

The Precision Manufacturing Process of the DQ-I Fixture

The creation of a DQ-I Fine Wire Conductor Resistance Fixture involves a meticulous multi-stage manufacturing process designed to ensure unparalleled precision and durability. It begins with the selection of high-grade raw materials, including aerospace-grade aluminum alloys for structural components and specialized insulating ceramics for critical contact areas. These materials undergo precision CNC machining to achieve exceptionally tight tolerances, often measured in micrometers, critical for the fixture's stability and repeatability. Surface treatments, such as hard anodizing for aluminum parts, enhance resistance to wear, corrosion, and electrical insulation properties, extending the fixture's service life. Gold plating is applied to contact points to ensure minimal contact resistance and excellent long-term conductivity. Each component then undergoes rigorous in-process quality inspections, including dimensional verification using CMM (Coordinate Measuring Machine) systems and material integrity checks. Final assembly occurs in a clean environment, followed by comprehensive functional testing and calibration against NIST-traceable standards. This adherence to ISO 9001 certified processes ensures that every DQ-I Fine Wire Conductor Resistance Fixture delivers consistent, reliable performance for industries such as specialized electronics manufacturing, medical device production, and high-performance automotive component testing, where precision is non-negotiable.

Key Technical Advantages of the DQ-I Fine Wire Conductor Resistance Fixture

The DQ-I Fine Wire Conductor Resistance Fixture offers a distinct set of technical advantages that set it apart in the market. Its robust mechanical design ensures long-term stability and minimal deflection, which is crucial for maintaining consistent contact with fine wires over countless test cycles. The precision-engineered clamping mechanism provides uniform pressure distribution, preventing damage to delicate conductors while ensuring optimal electrical contact. The fixture’s superior insulation properties prevent leakage currents, which can significantly affect resistance measurements, especially in the micro-ohm range. This high insulation resistance, combined with the four-wire Kelvin method, delivers unparalleled accuracy and repeatability, often achieving measurement repeatability better than 0.1%. Furthermore, its ergonomic design facilitates quick and easy sample loading and unloading, boosting testing throughput without compromising measurement integrity. These advantages directly translate into enhanced product quality, reduced waste from inaccurate measurements, and improved operational efficiency for manufacturers and research institutions.

Diverse Application Scenarios Across Critical Industries

The versatility and precision of the DQ-I Fine Wire Conductor Resistance Fixture make it indispensable across a multitude of high-tech industries. In the electronics sector, it's vital for quality control of bond wires, coil windings in miniature motors, and precision resistors used in PCBs. The automotive industry relies on it for testing sensor wires, cabling in ADAS (Advanced Driver-Assistance Systems), and components within electric vehicle battery packs, where consistent conductivity directly impacts safety and performance. Medical device manufacturers use it to verify the integrity of catheter wires, pacemaker leads, and other critical implantable components where even minor deviations in resistance can have severe consequences. Aerospace and defense applications leverage the fixture for testing high-reliability wiring in avionics and satellite communication systems. Lastly, in research and development, the DQ-I Fine Wire Conductor Resistance Fixture is a crucial tool for characterizing new conductive materials and optimizing wire manufacturing processes, facilitating innovation and driving advancements in material science.

Manufacturer Comparison and Why DQ-I Stands Out

While several manufacturers offer resistance measurement fixtures, the DQ-I stands out due to its superior engineering, consistent performance, and adherence to global standards. Many generic fixtures struggle with the unique challenges of fine wire testing, often leading to inconsistent contact, wire damage, or significant measurement errors due to poor insulation or lack of true Kelvin connections. The DQ-I's dedicated design for fine wires, incorporating specialized contact geometry and robust materials, provides a distinct advantage. Compared to competitors who may offer multi-purpose fixtures that are "adequate" for fine wires, the DQ-I Fine Wire Conductor Resistance Fixture is purpose-built, optimizing every aspect for this specific application. Our decades of experience in test equipment manufacturing, combined with rigorous in-house testing and external certifications, ensure that DQ-I fixtures not only meet but often exceed industry expectations for accuracy, repeatability, and durability. This commitment to specialized excellence translates into more reliable test results and greater confidence in your product's performance.

Tailored Solutions: Customization and Integration

Recognizing that unique testing requirements often emerge from specialized applications, we offer customized solutions for the DQ-I Fine Wire Conductor Resistance Fixture. Whether you require specific wire length accommodations, custom contact configurations for non-standard wire geometries, or integration with existing automated test platforms, our engineering team can design a tailored solution. We work closely with clients to understand their precise needs, providing design consultations, rapid prototyping, and meticulous validation to ensure the customized fixture perfectly aligns with their operational workflows and measurement objectives. This bespoke approach extends beyond mere modifications; it encompasses seamless integration with various resistance meters, data acquisition systems, and laboratory automation software, ensuring that the DQ-I fixture becomes a versatile and integral part of your comprehensive quality assurance or research infrastructure. Our aim is to provide not just a product, but a complete solution that enhances your testing capabilities and streamlines your processes.

Real-World Impact: DQ-I Fine Wire Conductor Resistance Fixture in Action

Our DQ-I Fine Wire Conductor Resistance Fixture has consistently delivered measurable value across various industries. For instance, a leading manufacturer of high-precision sensors for autonomous vehicles significantly reduced their material waste and rework rates by 15% after implementing the DQ-I fixture, attributing the improvement to more accurate and reliable incoming material inspection of micro-coils. In the medical sector, a top-tier producer of cardiac leads achieved a 20% faster quality control throughput, while maintaining stringent ISO 13485 compliance, thanks to the fixture’s user-friendly design and consistent repeatability. These real-world applications underscore the DQ-I's ability to not only meet but exceed expectations for critical fine wire testing. The fixture provides the reliable data needed for material validation, process optimization, and final product quality assurance, fostering greater trust in the integrity of products that rely on these delicate conductors. These success stories are a testament to the DQ-I's role in driving quality and efficiency in demanding technical environments.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for ordering a DQ-I Fine Wire Conductor Resistance Fixture?

- A: Standard configurations typically ship within 2-3 weeks, depending on current demand. Customized solutions may require a longer lead time, which will be quoted individually based on complexity.

- Q: How often does the DQ-I fixture require calibration?

- A: While the fixture itself is a passive component and doesn't require calibration in the traditional sense, its performance relies on the precision of your resistance meter. We recommend annual verification of the fixture's mechanical stability and contact integrity, along with regular calibration of your measurement instrumentation as per its manufacturer's guidelines.

- Q: Is the DQ-I compatible with all types of resistance meters?

- A: The DQ-I is designed with standard banana plug connectors for current and voltage leads, making it compatible with most commercially available precision resistance meters and multi-meters that support the four-wire Kelvin method. We can provide guidance on specific meter compatibility if needed.

Delivery, Warranty, and Unparalleled Customer Support

We are committed to delivering the DQ-I Fine Wire Conductor Resistance Fixture promptly and efficiently. Our standard delivery lead time for off-the-shelf units is typically 2-3 weeks, while custom configurations will have a lead time specified upon order confirmation. Every DQ-I fixture comes with a comprehensive 12-month warranty covering manufacturing defects and material failures, underscoring our confidence in its quality and durability. Beyond the warranty period, we offer robust technical support, including troubleshooting assistance, spare parts availability, and repair services. Our dedicated customer support team is readily available to assist with any queries, ensuring your investment continues to perform optimally for years to come. We also provide detailed user manuals and application notes to help you maximize the utility and precision of your DQ-I Fine Wire Conductor Resistance Fixture, reflecting our commitment to your long-term success.

References

- Institute of Electrical and Electronics Engineers (IEEE) – Standards for Electrical Measurement.

- American Society for Testing and Materials (ASTM) – Standard Test Method for Resistivity of Electrical Conductor Materials.

- International Electrotechnical Commission (IEC) – Standards for Winding Wires.

- National Institute of Standards and Technology (NIST) – Guidelines for Resistance Metrology.

- Journal of Electronic Materials – Peer-reviewed articles on conductor properties and testing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy