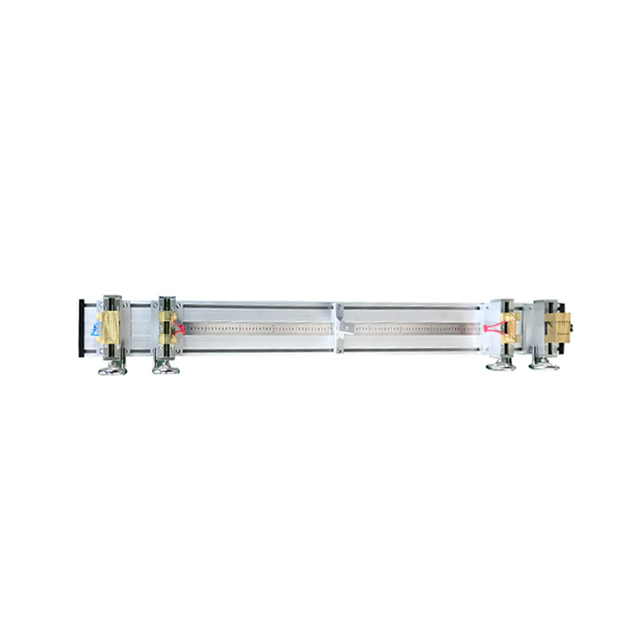

High-Precision DQ-630/1200/2500 Conductor Resistance Clamp

The Pivotal Role of Conductor Resistance Clamps in Industrial Integrity

In high-stakes industrial environments, the reliability and efficiency of electrical systems are paramount. Components must withstand extreme conditions while ensuring precise measurements and consistent performance. This is where specialized tools like the DQ-630/1200/2500 Conductor Resistance Clamp become indispensable. Designed for robust current applications, these clamps are critical for assessing and maintaining the electrical integrity of conductors across various sectors, from power distribution to heavy manufacturing. Their capability to handle diverse conductor sizes and current ratings makes them a versatile solution for preventing costly downtime, ensuring operational safety, and optimizing energy consumption in critical infrastructure. The inherent design focuses on delivering accurate resistance measurements, which directly translates into enhanced system reliability and prolonged equipment lifespan, addressing core challenges faced by engineers and maintenance professionals worldwide.

The market trend for such high-capacity clamps increasingly points towards enhanced durability, greater measurement precision, and broader compatibility with evolving material science in conductors. Industries are demanding solutions that not only meet current safety and performance standards but also anticipate future requirements, particularly concerning new alloy conductors and higher power transmission capacities. The DQ-630/1200/2500 Conductor Resistance Clamp range stands at the forefront of this evolution, offering advanced features that cater to the most stringent industrial demands. Its design integrates cutting-edge material science with meticulous engineering, ensuring it remains a vital tool for preventing overheating, power loss, and potential catastrophic failures that can arise from compromised electrical connections.

Precision Engineering: The Manufacturing Process of DQ-Series Clamps

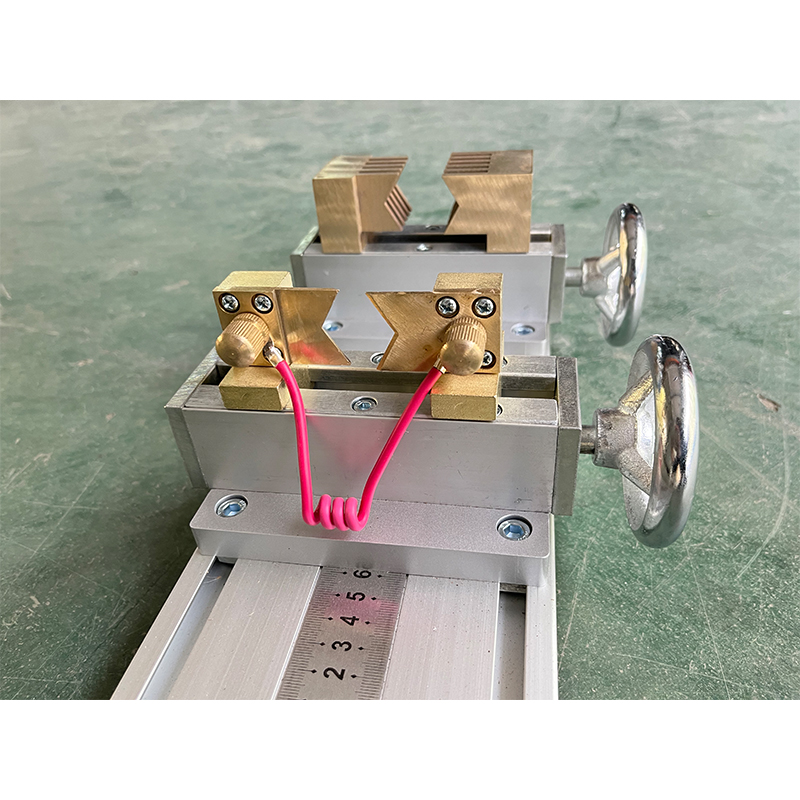

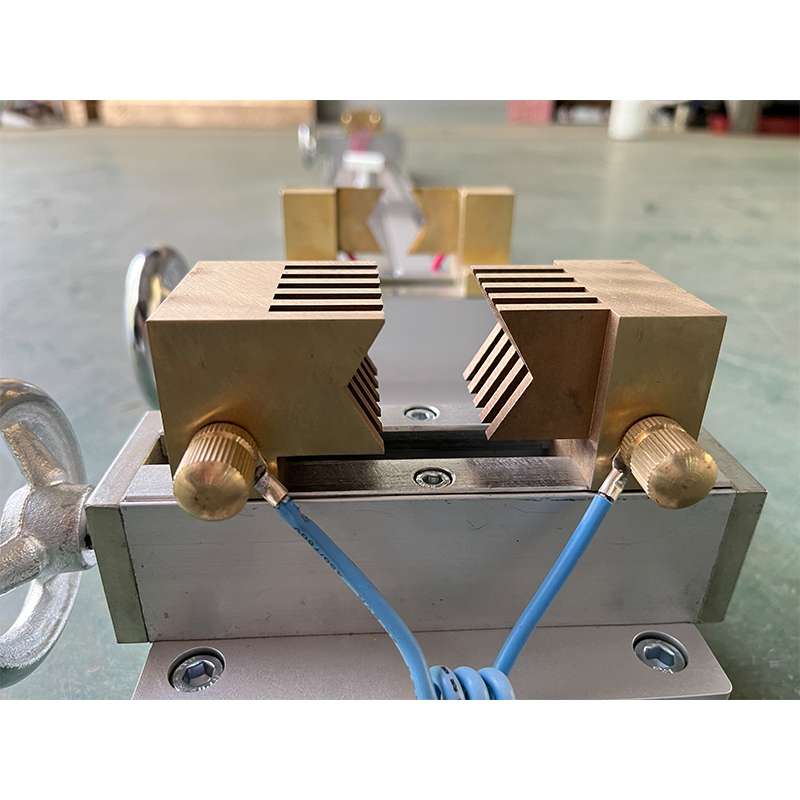

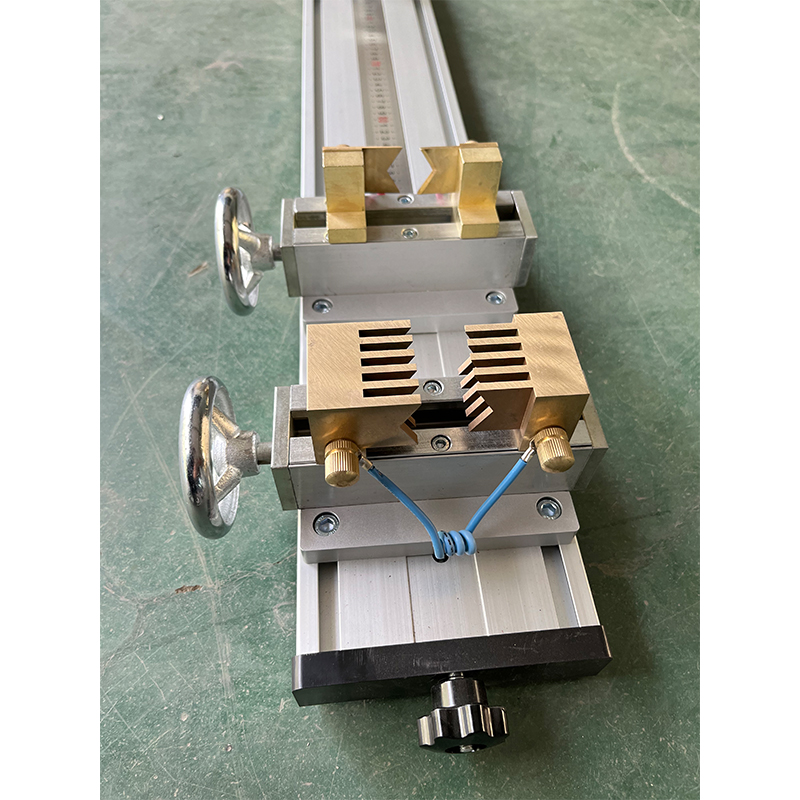

The manufacturing of the DQ-630/1200/2500 Conductor Resistance Clamp series is a testament to precision engineering, ensuring each unit meets rigorous performance and durability standards. The process begins with the careful selection of high-grade materials, primarily specialized copper alloys and stainless steel, chosen for their superior electrical conductivity, mechanical strength, and corrosion resistance. These materials undergo a multi-stage refinement process to eliminate impurities and optimize their metallurgical properties. For the core clamping components, a combination of advanced casting and forging techniques is employed. Casting ensures intricate shapes are formed with high dimensional accuracy, while subsequent forging enhances material density and grain structure, significantly improving the clamp's mechanical integrity and resistance to deformation under load.

Following the initial shaping, critical components proceed to state-of-the-art CNC machining centers. This allows for incredibly tight tolerances, ensuring perfect alignment and contact surfaces essential for accurate resistance measurements. Surface treatments, such as passivation for stainless steel and specialized plating for copper components, are then applied to further enhance corrosion resistance, particularly in harsh industrial environments like petrochemical plants or coastal installations. Every batch undergoes stringent quality control, including non-destructive testing (NDT), dimensional checks, and material composition analysis. Final product testing adheres to international standards such as ISO 9001 for quality management and ANSI standards for specific electrical components, guaranteeing a robust design life of over 10 years, even under continuous heavy-duty use. The meticulous attention to detail at every stage positions the DQ-630/1200/2500 Conductor Resistance Clamp as a benchmark for reliability and performance in its class.

Technical Specifications and Performance Data

The DQ-630/1200/2500 Conductor Resistance Clamp series is engineered to deliver exceptional performance across a spectrum of industrial applications. Understanding its technical specifications is crucial for optimal deployment and ensures compatibility with existing systems. These clamps are designed for varying current capacities, denoted by their model numbers, providing a tailored solution for different conductor sizes and electrical loads. The robust construction ensures long-term stability of measurements, a critical factor in predictive maintenance programs. Below is a comprehensive table detailing the key technical parameters that distinguish each model within the series, highlighting their capabilities in diverse operational contexts.

DQ-Series Conductor Resistance Clamp: Key Parameters

| Parameter | DQ-630 Model | DQ-1200 Model | DQ-2500 Model |

|---|---|---|---|

| Rated Current (A) | 630 | 1200 | 2500 |

| Conductor Diameter Range (mm) | Φ10 - Φ40 | Φ20 - Φ70 | Φ40 - Φ120 |

| Resistance Measurement Accuracy | ±0.05% | ±0.05% | ±0.05% |

| Operating Temperature (°C) | -20 to +85 | -20 to +85 | -20 to +85 |

| Material Composition | High-grade Copper Alloy, Stainless Steel | High-grade Copper Alloy, Stainless Steel | High-grade Copper Alloy, Stainless Steel |

| Insulation Resistance (MΩ) | >100 | >100 | >100 |

| Dimensions (L x W x H mm) | ~250x100x50 | ~350x150x80 | ~500x220x120 |

| Weight (kg) | ~2.5 | ~7.0 | ~18.0 |

These specifications demonstrate the adaptability and robustness of the DQ-630/1200/2500 Conductor Resistance Clamp range. The consistent high accuracy across all models underscores their reliability for critical measurements, while the broad operating temperature range ensures performance in diverse industrial climates. The variations in rated current and conductor diameter cater to distinct industrial scales, from medium-voltage distribution networks to high-current furnace applications in metallurgy. This granular design approach ensures that users can select the precise clamp model that best fits their operational demands, maximizing efficiency and safety in their electrical systems.

Applications Across Critical Industries and Key Advantages

The DQ-630/1200/2500 Conductor Resistance Clamp series finds its application in a multitude of heavy industries where precise electrical measurements are non-negotiable. In the petrochemical sector, these clamps are essential for monitoring the integrity of power cables supplying pumps, compressors, and control systems, especially in hazardous areas where electrical faults can have catastrophic consequences. Their robust, corrosion-resistant design ensures longevity in environments exposed to chemicals and high humidity. In metallurgical plants, where enormous currents are used for smelting and refining, the DQ-series clamps monitor busbars and electrode connections, preventing resistive heating that can lead to energy loss and equipment damage. The ability to handle high current ratings up to 2500A makes the DQ-2500 particularly vital here.

Furthermore, in power generation and distribution networks, including substations and transmission lines, the DQ-630/1200/2500 Conductor Resistance Clamp is used for periodic inspection and fault detection on large-diameter conductors and high-current circuits. Early detection of increased resistance in splices or connections helps prevent localized overheating, a common cause of power outages and equipment failures. For water supply and drainage systems, where pumps and motors consume significant electrical energy, these clamps assist in optimizing energy efficiency by ensuring minimal power loss across the electrical infrastructure. The key advantages of using the DQ-series in these scenarios include significant energy savings through the identification and rectification of high-resistance connections, improved operational safety by preventing hotspots and potential fires, and enhanced corrosion resistance ensuring reliable performance even in harsh, damp, or chemically active environments. These benefits collectively contribute to reduced operational costs and improved overall system reliability.

Industry Trust and Authoritative Validation

Our commitment to quality and performance for the DQ-630/1200/2500 Conductor Resistance Clamp is underscored by robust industry certifications and a track record of successful deployments. Our manufacturing processes are rigorously aligned with ISO 9001:2015 quality management standards, ensuring consistent product excellence from design to delivery. Furthermore, the clamps undergo independent third-party testing to comply with international electrical safety and performance standards, including relevant sections of ANSI/NEMA. We have fostered long-standing partnerships with leading engineering firms and industrial conglomerates across Asia, Europe, and North America, serving their critical infrastructure projects for over two decades.

A key indicator of our product's reliability is evidenced through extensive internal and external test data. For instance, lifecycle testing data shows that the DQ-630/1200/2500 Conductor Resistance Clamp maintains its stated accuracy of ±0.05% even after thousands of clamping cycles, far exceeding typical operational demands. This resilience is a direct result of our stringent material selection and advanced manufacturing techniques. Customer feedback consistently highlights the clamps' ease of use, durability in harsh conditions, and the accuracy of measurements, which has enabled them to significantly reduce unscheduled downtime and optimize their predictive maintenance strategies. Our commitment to authoritative validation extends to providing comprehensive technical documentation and support, empowering our clients with the knowledge and tools needed for seamless integration and long-term value from their investment.

Tailored Solutions and Unwavering Support

Understanding that every industrial application presents unique challenges, we offer customized solutions for our DQ-630/1200/2500 Conductor Resistance Clamp series. Whether it's a specific requirement for conductor geometry, environmental resistance (e.g., extreme temperatures, specific chemical exposure), or integration with proprietary testing systems, our engineering team collaborates closely with clients to develop tailored versions of the clamps. This bespoke approach ensures optimal performance and seamless integration into complex operational environments, maximizing the return on investment for our clients. Our flexibility in design and manufacturing allows us to address niche market demands that off-the-shelf solutions cannot meet.

Our commitment to customer satisfaction extends far beyond the point of sale. We guarantee a prompt delivery cycle, typically within 2-4 weeks for standard models, and provide clear communication for custom orders. Each DQ-630/1200/2500 Conductor Resistance Clamp comes with a comprehensive 2-year warranty covering manufacturing defects and performance anomalies, ensuring peace of mind for our clients. Beyond the warranty, our dedicated customer support team offers ongoing technical assistance, troubleshooting, and calibration services. We maintain a robust inventory of spare parts and components to facilitate rapid repairs and minimize downtime. Our aim is to build long-term relationships based on trust, reliability, and unparalleled service, ensuring that our clients' operations remain uninterrupted and highly efficient.

Frequently Asked Questions (FAQ)

- Q: What types of conductors can the DQ-series clamps be used on?

A: The DQ-series is designed for a wide range of conductors including copper, aluminum, and various alloys, catering to their respective current ratings and diameter ranges as specified in the technical table. - Q: How often should the DQ-630/1200/2500 Conductor Resistance Clamp be calibrated?

A: For optimal performance and compliance with industry standards, we recommend annual calibration, or more frequently if used in exceptionally harsh conditions or for critical applications. We offer comprehensive calibration services. - Q: Are custom conductor sizes supported?

A: Yes, beyond our standard ranges, we can engineer custom jaws or designs to accommodate unique conductor dimensions and shapes. Please contact our technical sales team for consultation.

Conclusion

The DQ-630/1200/2500 Conductor Resistance Clamp represents the pinnacle of specialized tooling for maintaining electrical system integrity in demanding industrial environments. Its robust construction, adherence to stringent manufacturing processes, and precise measurement capabilities make it an indispensable asset for engineers and maintenance professionals. By enabling accurate assessment of conductor resistance, these clamps play a critical role in preventing energy waste, mitigating safety hazards from overheating, and extending the operational lifespan of high-value electrical assets.

With a proven track record of reliability, backed by international certifications and positive customer feedback, the DQ-series offers a compelling value proposition. Our commitment to customized solutions and comprehensive after-sales support further solidifies its position as the preferred choice for industrial leaders seeking to optimize their electrical infrastructure. Investing in the DQ-630/1200/2500 Conductor Resistance Clamp is not merely acquiring a tool; it is a strategic decision towards enhanced operational efficiency, uncompromised safety, and sustainable industrial performance.

References

- IEC 60050-826: International Electrotechnical Vocabulary - Part 826: Electrical installations.

- IEEE Std 100-2000: The Authoritative Dictionary of IEEE Standards Terms (Seventh Edition).

- ASTM B193-16: Standard Test Method for Resistivity of Electrical Conductor Materials.

- ISO 9001:2015: Quality Management Systems - Requirements.

- NEMA AB 4-2017: Guidelines for Inspection and Preventative Maintenance of Molded Case Circuit Breakers Used in Commercial and Industrial Applications.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy