Tools for Assessing Vision in Projector Manufacturing Facilities

Instruments for Measuring Vision An Insight into Projector Factory Innovations

Vision measurement is a crucial element in various industries, especially in healthcare, automotive, manufacturing, and engineering. The significance of accurate vision assessment tools has led to the development of specialized instruments in numerous settings, including projector factories. These instruments serve not only to measure visual acuity but also to evaluate optical parameters, ensuring that projections meet the necessary quality standards for clarity and precision.

The Evolution of Vision Measurement Instruments

Historically, vision assessment began with simple tools like Snellen charts, which helped in determining an individual's visual acuity. With advances in technology, the methods and instruments used for measuring vision have evolved remarkably. Today, projector factories utilize sophisticated equipment designed to provide comprehensive data about visual capabilities.

Modern vision measurement tools include automated refractors, wavefront aberration sensors, and ocular coherence tomography devices. Each of these instruments plays a pivotal role in understanding various aspects of human vision, allowing for precise adjustments to be made in products such as projectors that require impeccable clarity and focus.

The Role of Projector Factories

Projector factories focus on producing high-quality projection systems for various applications, from educational environments to corporate presentations, and even large-scale entertainment productions. To ensure that their products deliver optimal performance, these factories integrate state-of-the-art vision measurement instruments in their production lines.

By employing these advanced tools, manufacturers can assess and calibrate the optical systems of projectors. This involves checking factors such as brightness, contrast, color accuracy, and resolution. The more accurately these parameters are measured and optimized, the better the projection quality becomes, which is essential in maintaining competitiveness in the market.

Key Instruments Used

1. Photometers These devices measure luminous intensity and are essential for assessing the brightness levels of projector outputs. By ensuring that the brightness meets the required specifications, manufacturers can enhance user experience during presentations and displays.

instruments for measuring vision projector factory

2. Colorimeter This instrument measures the color output of projectors. Accurate color reproduction is critical for applications in fields like advertising and media, where visual content must appear true to life. By utilizing colorimeters, projector factories are better equipped to ensure that their devices maintain color fidelity.

3. Resolution Test Patterns Projector factories often utilize high-precision resolution test patterns to evaluate the sharpness and detail of projected images. These patterns help identify any distortions or inconsistencies in the projection system, enabling manufacturers to make necessary adjustments during production.

4. Contrast Ratio Testers Contrast is vital for image clarity, and these testers allow for accurate measurement of the contrast ratio of projectors. A higher contrast ratio generally indicates better picture quality, making this a key parameter for evaluating projector performance.

5. Optical Bench Systems These systems are used to evaluate the optical performance of projectors comprehensively. They provide in-depth analysis concerning how light travels through projector lenses and can identify aberrations that may affect image quality.

The Importance of Precision

The integration of these instruments in projector factories underscores the importance of precision in the production process. Customers today demand high-quality visuals, and any shortcomings in projector performance can lead to dissatisfaction and a tarnished brand reputation.

By leveraging advanced technology for vision measurement, projector manufacturers can ensure that each unit produced meets stringent quality standards. These investments not only bolster the reliability of the product but also enhance brand loyalty among consumers who rely on high-performance projectors for various applications.

Conclusion

In summary, the relationship between vision measurement instruments and projector factories is a symbiotic one that facilitates the production of high-quality projection systems. As technology evolves, the sophistication and capabilities of these instruments will continue to grow, further improving the quality of projector outputs. Ultimately, the commitment to precision in vision measurement will drive innovation and excellence in the projection industry, ensuring that manufacturers remain at the forefront of visual technology for years to come.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

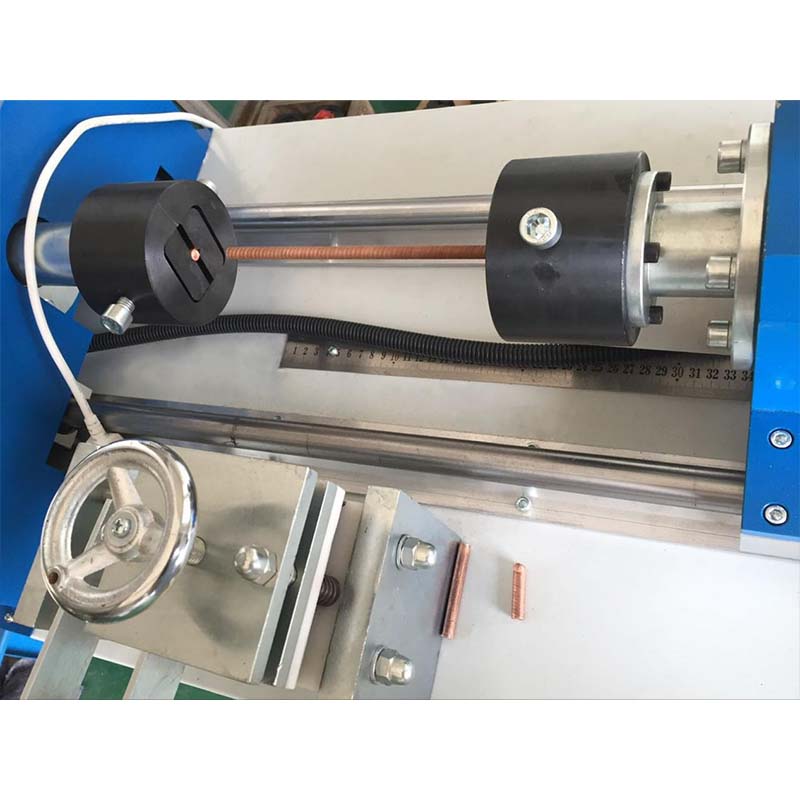

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy