Shear Strength Evaluation Using Tensile Testing Methods in Material Analysis

Understanding Tensile Testers and Shear Strength Measurements

In the realm of materials science and engineering, understanding the mechanical properties of materials is crucial for designing and manufacturing products that are safe and efficient. Among the various methods used to evaluate these properties, tensile testing stands out as one of the most fundamental techniques. Tensile testers provide critical data on a material's strength and ductility, allowing engineers to make informed decisions when selecting materials for specific applications.

Tensile testing involves applying a pulling force to a material specimen until it deforms or breaks. The primary goal of this testing is to measure two key parameters tensile strength and elongation. Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failing, while elongation indicates how much a material can stretch before breaking. However, another important aspect closely related to tensile testing is the concept of shear strength, which plays a vital role in evaluating a material's performance under different loading conditions.

Shear strength refers to the maximum stress that a material can withstand in a shearing condition before failure. Unlike tensile stress, which involves pulling forces, shear stress arises when forces are applied parallel to a material's surface, causing layers of the material to slide past each other. This property is particularly relevant in structural applications where components are subjected to various forces, not just tensile loads. For example, in bolted connections, shear strength is critical as it determines how much load the connection can bear without failing.

To accurately gauge the shear strength of materials, various testing methodologies can be employed alongside tensile testing. These methods include shear tests performed on specimens cut into specific shapes conducive to measuring shear force, such as slotted specimens or notched specimens. The use of a tensile tester adapted for shear testing can provide reliable data.

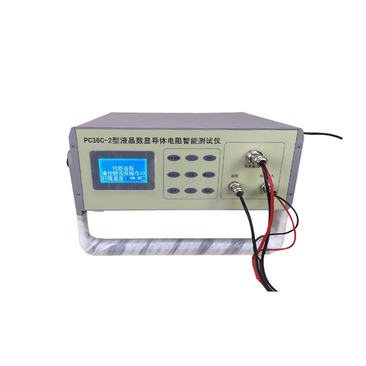

tensile tester shear strength

The results obtained from tensile and shear tests inform engineers about a material's overall performance and reliability in a given application. For instance, materials such as steel exhibit high tensile and shear strengths, making them suitable for construction applications where significant loads are common. Conversely, materials like polymers may have lower shear strengths and are often used in applications where flexibility is prioritized over load-bearing capacity.

Additionally, factors such as temperature, rate of loading, and material composition can influence both tensile and shear strength measurements. Engineers must consider these variables when interpreting test results and applying them to real-world applications. For example, some materials may become more brittle at lower temperatures, leading to a rapid decrease in their performance under tensile or shear loads.

The use of advanced tensile testers has revolutionized how engineers assess materials. Modern equipment can provide high precision and real-time data analysis, allowing for faster and more effective material evaluations. These devices often include software that can analyze stress-strain curves, helping engineers understand the material's behavior under different loading scenarios and improve designs accordingly.

In conclusion, tensile testing and the measurement of shear strength are indispensable in the field of materials science and engineering. By thoroughly understanding these concepts, engineers can select the appropriate materials and design safe and efficient structures and components. The integration of advanced testing devices further enhances the accuracy and reliability of these evaluations, ensuring that materials will perform as expected in their intended applications. As industries continue to evolve and demand materials with superior performance, the importance of tensile and shear strength testing will remain a cornerstone of engineering practices.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy