Cable Heat Set Testing Services for Reliable Performance and Safety Assurance

The Importance of Cable Hot Set Testing in Quality Assurance

In today's interconnected world, reliable cable systems are more important than ever. They form the backbone of telecommunications, power transmission, and numerous industrial applications. As such, the integrity of these cables must be rigorously tested to ensure safety and reliability. One of the essential testing methods used in the cable manufacturing industry is hot set testing, a vital process for understanding the thermal properties and behavior of cable materials under stress.

Hot set testing, often known as heat aging or thermal stability testing, evaluates a cable's performance when exposed to elevated temperatures. The primary objective is to assess how the cable materials will react in conditions similar to those they will encounter in real-world applications. This kind of testing is particularly crucial for cables that are expected to operate in high-temperature environments, such as those found in industrial settings, aerospace, and automotive industries.

The Importance of Cable Hot Set Testing in Quality Assurance

During a typical hot set test, samples are subjected to a pre-defined temperature while being simultaneously stretched. This process mimics the thermal and mechanical stresses that cables would usually face during their lifecycle. The results reveal important data about the material's ability to maintain its shape, avoid deformation, and resist wear and tear over time. By understanding these characteristics, manufacturers can make more informed decisions about their product designs and materials.

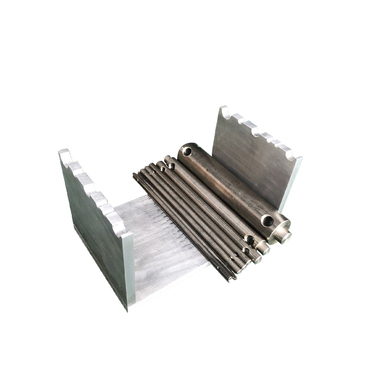

cable hot set testing company

Moreover, collaboration with a reliable cable hot set testing company can help manufacturers streamline their production processes. By identifying potential weaknesses in their cables early in the production cycle, companies can implement changes that enhance the durability and longevity of their products. This proactive approach minimizes the risk of product failures and the associated costs of recalls and repairs, ultimately safeguarding the reputation of the manufacturer.

Regulatory compliance is another critical factor driving the need for hot set testing. Various industries have stringent standards and guidelines to ensure the safety and reliability of electrical components. Testing companies play a crucial role in helping manufacturers navigate these requirements. By providing expert insights and rigorous testing results, they help companies avoid costly penalties and ensure that their products are certified for market release.

In addition to compliance and quality assurance, the findings from hot set tests can also lead to innovations in cable technology. By analyzing the performance data, manufacturers can explore new materials and designs that enhance the thermal efficiency and durability of cables. This innovation is vital for meeting the increasing demands for high-performance cables in sectors such as renewable energy, electric vehicles, and advanced telecommunications systems.

In conclusion, the role of cable hot set testing companies is indispensable in today's technology-driven landscape. Their expertise in evaluating the thermal properties of cable materials not only ensures compliance with safety standards but also drives innovation in the industry. As the demand for more reliable and efficient cable systems continues to rise, the significance of rigorous testing will only grow. Manufacturers who prioritize hot set testing stand to benefit from enhanced product quality, reduced operational costs, and a strong competitive edge in a rapidly evolving market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy