Manufacturers of Equipment for Bunched Cable Burning Tests and Safety Standards

Understanding Cable Bunched Burning Test Equipment Manufacturers

In the realm of electrical safety, the importance of rigorous testing for cable and wire materials cannot be overstated. Cable bunched burning test equipment is essential for manufacturers and researchers aiming to assess the flammability and smoke-emitting characteristics of electrical cables when subjected to fire. This equipment is crucial for ensuring compliance with safety standards and for protecting lives and properties from fire hazards.

Cable bunched burning tests simulate conditions that cables may encounter in real-world scenarios, helping to determine how various cable configurations react to heat and flames. Manufacturers of this specialized equipment play a vital role in the development, testing, and implementation of safety protocols across numerous industries, including construction, telecommunications, and automotive.

Key Features of Cable Bunched Burning Test Equipment

When evaluating manufacturers of cable bunched burning test equipment, several key features should be considered

1. Compliance with Standards Equipment must meet international safety standards such as IEC 60332, UL 910, and other relevant guidelines. Manufacturers should provide certification and documentation proving that their equipment is compliant with the latest regulations.

2. Precision and Reliability The ability to produce consistent results across tests is paramount. Quality manufacturers invest in advanced technology to enhance the accuracy and reliability of their equipment.

3. User-Friendly Design The tests can be complex, and equipment should be designed with usability in mind. Features like intuitive interfaces, straightforward setup procedures, and clear instructions facilitate efficient operation.

cable bunched burning test equipment manufacturers

4. Safety Features Given the nature of the tests, safety is a priority. Manufacturers should incorporate features such as automatic shut-off mechanisms, flame suppression systems, and robust containment measures to protect operators.

5. Scalability Different applications may require various testing capacities. Manufacturers who offer scalable solutions enable industries to adapt their testing procedures according to their specific needs.

The Importance of Choosing the Right Manufacturer

Selecting the right manufacturer for cable bunched burning test equipment is critical for ensuring the integrity of the testing process. A reputable manufacturer not only provides high-quality equipment but also offers excellent customer support, including training and maintenance services. This ongoing assistance is vital for organizations that rely on consistent testing to meet safety standards.

Future Trends in Cable Bunched Burning Testing

As technology advances, manufacturers are increasingly integrating automation and digital monitoring into their equipment. This trend is likely to continue, improving the efficiency of testing processes and enabling more comprehensive data collection. Additionally, the growing emphasis on environmental sustainability may influence the development of new materials and testing protocols.

In conclusion, cable bunched burning test equipment manufacturers play a crucial role in promoting electrical safety. By choosing quality equipment from reputable manufacturers, industries can enhance their safety measures, comply with regulations, and ultimately contribute to a safer environment for everyone.

-

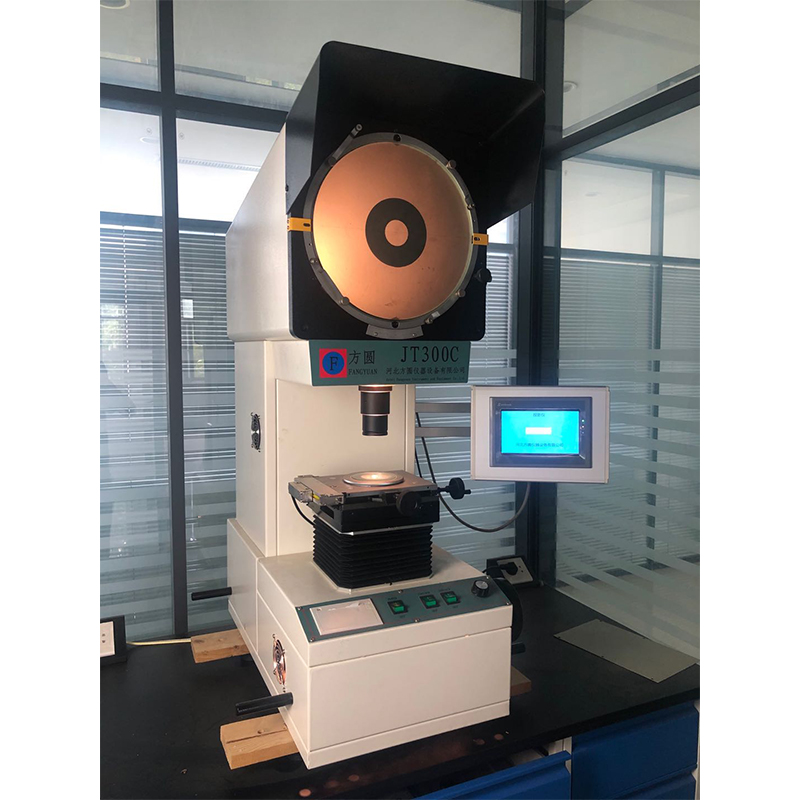

Unleashing the Potential of Digital Profile Projectors

NewsMay.22,2025

-

Smoke Density Test Machines for Fire Safety Assessment

NewsMay.22,2025

-

Revolutionizing Testing with Electronic Tensile Tester

NewsMay.22,2025

-

Innovations in Resistance Test Equipment

NewsMay.22,2025

-

Exploring High Performance Cable Cross Linking Equipment

NewsMay.22,2025

-

Advancements in Conductor Resistance Test Equipment

NewsMay.22,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy