ມ.ກ. . 23, 2025 01:52

Back to list

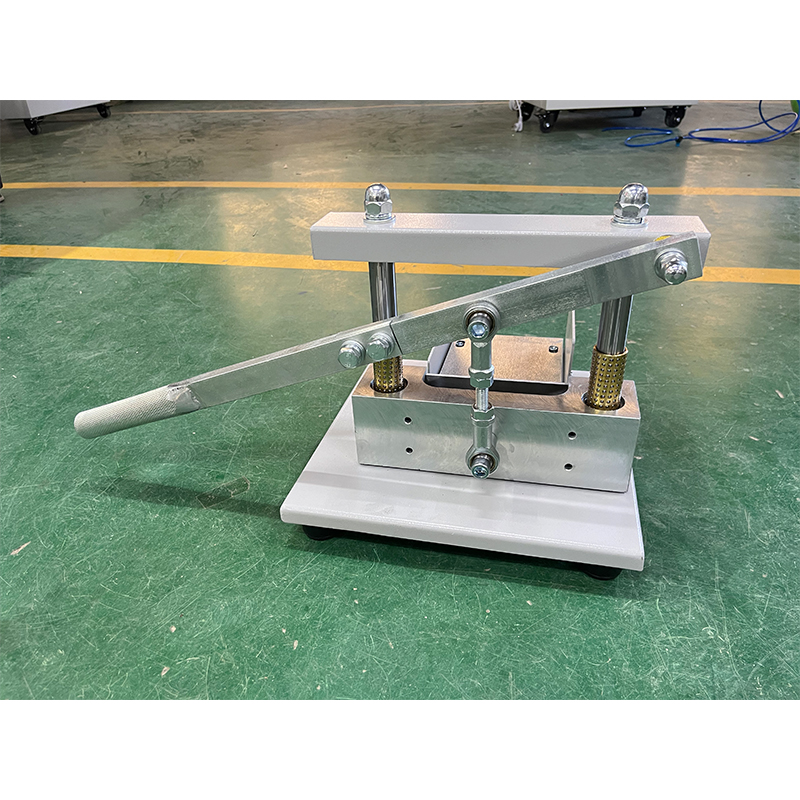

custom cable slicing machine

The precision and efficiency of a custom cable slicing machine have revolutionized the cable manufacturing industry, integrating state-of-the-art technology to meet diverse industrial needs. As companies worldwide seek innovative methods to produce high-quality and reliable cable products, the demand for advanced machinery such as custom cable slicing systems continues to soar. Understanding the core features and benefits of these machines is crucial for businesses looking to enhance their production capabilities while ensuring consistent output quality.

The authority of manufacturers of custom cable slicing machines stems from decades of innovation and customer-centric design improvements. Leading manufacturers invest consistently in research and development, monitoring industry trends and technological advancements to ensure their machines are ahead of market needs. These manufacturers often collaborate with their clients to provide tailored solutions, addressing specific operational challenges and enabling clients to maintain a competitive edge in the industry. From an experiential standpoint, businesses that integrate custom cable slicing machines into their production lines gain an operational advantage through increased throughput and reduced error rates. Production managers often report that these machines not only streamline their operations but also heighten the quality of their final products, giving them a competitive advantage in meeting customer expectations. Additionally, deep analysis and data-driven insights provided by the machine’s integrated software enhance operators’ capacity to monitor and optimize production processes. Detailed reports and diagnostic tools help in identifying inefficiencies or potential issues before they manifest, ensuring that machine maintenance can be conducted proactively, further extending the equipment’s operational life and reliability. Ultimately, investing in a custom cable slicing machine represents a commitment to maintaining high production standards and meeting evolving client demands with precision and reliability. As technology advances, these machines will continue to play a pivotal role in industrial production settings, offering the expertise, authority, and trustworthiness that businesses need to thrive in competitive markets.

The authority of manufacturers of custom cable slicing machines stems from decades of innovation and customer-centric design improvements. Leading manufacturers invest consistently in research and development, monitoring industry trends and technological advancements to ensure their machines are ahead of market needs. These manufacturers often collaborate with their clients to provide tailored solutions, addressing specific operational challenges and enabling clients to maintain a competitive edge in the industry. From an experiential standpoint, businesses that integrate custom cable slicing machines into their production lines gain an operational advantage through increased throughput and reduced error rates. Production managers often report that these machines not only streamline their operations but also heighten the quality of their final products, giving them a competitive advantage in meeting customer expectations. Additionally, deep analysis and data-driven insights provided by the machine’s integrated software enhance operators’ capacity to monitor and optimize production processes. Detailed reports and diagnostic tools help in identifying inefficiencies or potential issues before they manifest, ensuring that machine maintenance can be conducted proactively, further extending the equipment’s operational life and reliability. Ultimately, investing in a custom cable slicing machine represents a commitment to maintaining high production standards and meeting evolving client demands with precision and reliability. As technology advances, these machines will continue to play a pivotal role in industrial production settings, offering the expertise, authority, and trustworthiness that businesses need to thrive in competitive markets.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy