ກ.ພ. . 16, 2025 08:21

Back to list

projector measuring machine company

The realm of tensile testing machines is integral to quality assurance in diverse industries ranging from aerospace and automotive to construction and biomedical sectors. Selecting a reliable supplier is crucial in ensuring the precision and dependability of the testing machines. This article delves into the intricacies of choosing the right tensile testing machine suppliers, offering insights from industry experience, professional expertise, authority, and trustworthiness perspectives.

Evaluating Your Supplier Key Considerations When vetting potential tensile testing machine suppliers, consider the following factors 1. Track Record Scrutinize the supplier's history in the industry. Lengthy, successful tenure often indicates reliability. 2. Clientele Portfolio Examine their clientele list. Serving reputable brands and companies is a positive indication of their credibility. 3. Service Spectrum Assess the breadth of their services. Comprehensive pre-sale, installation, and post-sale services are critical. 4. Technology and Training Ensure the supplier employs cutting-edge technology and offers ample training to your team. 5. Feedback and Reviews Look for authentic customer reviews and feedback. High customer satisfaction ratings are good indicators. 6. Geographical Reach and Support Ensure the supplier offers local service support to address potential technical issues promptly. Conclusion Making an Informed Decision In conclusion, the process of selecting the right tensile testing machine supplier requires careful consideration of experience, expertise, authoritativeness, and trustworthiness. Investing time into researching and evaluating suppliers based on these factors ensures that the table is set for optimal testing processes that uphold product integrity. Leveraging a supplier that embodies these characteristics helps build not only a robust testing setup but also a partnership, facilitating shared growth and advancement in quality assurance. As the industry continues to evolve, staying informed about the latest advancements and maintaining robust relationships with esteemed suppliers will always place a business ahead of the curve, ensuring sustained success and innovation in material testing.

Evaluating Your Supplier Key Considerations When vetting potential tensile testing machine suppliers, consider the following factors 1. Track Record Scrutinize the supplier's history in the industry. Lengthy, successful tenure often indicates reliability. 2. Clientele Portfolio Examine their clientele list. Serving reputable brands and companies is a positive indication of their credibility. 3. Service Spectrum Assess the breadth of their services. Comprehensive pre-sale, installation, and post-sale services are critical. 4. Technology and Training Ensure the supplier employs cutting-edge technology and offers ample training to your team. 5. Feedback and Reviews Look for authentic customer reviews and feedback. High customer satisfaction ratings are good indicators. 6. Geographical Reach and Support Ensure the supplier offers local service support to address potential technical issues promptly. Conclusion Making an Informed Decision In conclusion, the process of selecting the right tensile testing machine supplier requires careful consideration of experience, expertise, authoritativeness, and trustworthiness. Investing time into researching and evaluating suppliers based on these factors ensures that the table is set for optimal testing processes that uphold product integrity. Leveraging a supplier that embodies these characteristics helps build not only a robust testing setup but also a partnership, facilitating shared growth and advancement in quality assurance. As the industry continues to evolve, staying informed about the latest advancements and maintaining robust relationships with esteemed suppliers will always place a business ahead of the curve, ensuring sustained success and innovation in material testing.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

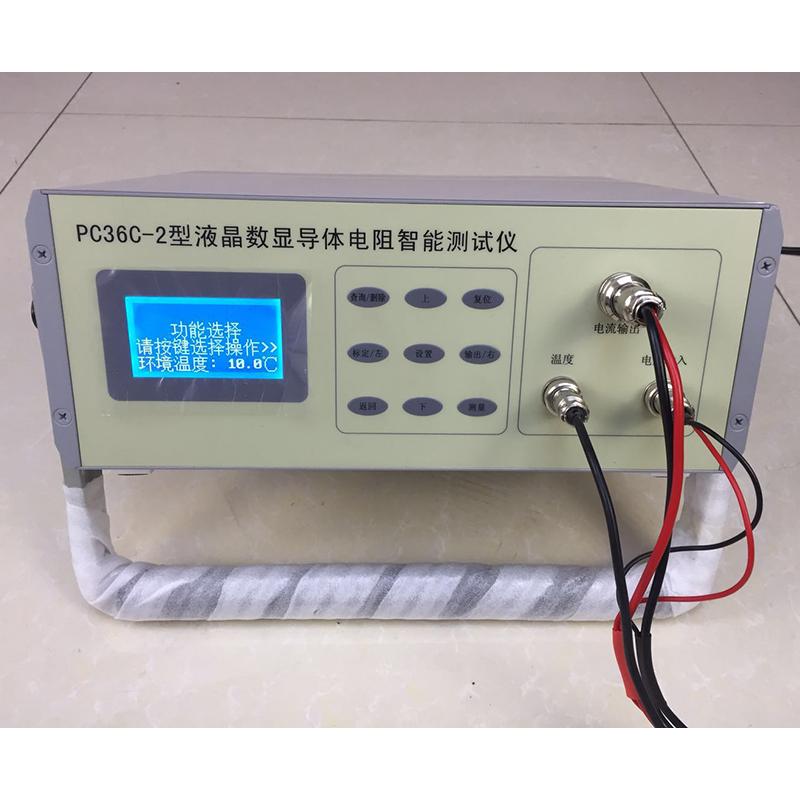

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy