Cable Insulation Stripping Equipment for Efficient Wire Processing and Cutting Solutions

The Importance of Cable Insulation Cut Machines in Modern Manufacturing

In today's fast-paced and technologically-driven world, the efficiency of manufacturing processes plays a crucial role in determining the overall productivity and profitability of industries. One of the essential components in the cable manufacturing sector is the cable insulation cut machine. This specialized equipment is designed to streamline the process of cutting and stripping insulation from wires, ensuring accuracy and reducing waste in production.

Understanding Cable Insulation Cutting

Cable insulation cut machines have become indispensable in various industries, including telecommunications, automotive, and electronics. The primary function of these machines is to remove the outer insulation layer from electrical cables, exposing the conductive materials beneath. This process is critical for preparing cables for further procedures such as soldering, solderless connections, or assembly into larger systems.

The mechanism of cable insulation cutting involves precision engineering. Most modern machines are equipped with high-speed rotary blades or hot wire systems that can cut through different types of insulation materials, including PVC, rubber, and thermoplastics. Proper insulation removal is vital as it ensures the integrity and functionality of the cable, allowing for optimal electrical conductivity.

The Benefits of Using Cable Insulation Cut Machines

1. Efficiency and Speed One of the most significant advantages of employing cable insulation cut machines is the increase in production speed. Manual cutting can be time-consuming and labor-intensive, while automated machines can process hundreds of cables per hour. This efficiency translates to higher output and reduced lead times for manufacturers.

2. Precision and Accuracy The modern cable insulation cut machines are designed to deliver precise cuts consistently. This precision minimizes the risk of damaging the wire itself during the insulation removal process, which can often occur with manual cutting methods. By ensuring clean cuts, the machines contribute to the overall quality of the finished product.

cable insulation cut machine

3. Reduction of Waste In manufacturing, minimizing waste is critical for cost-effectiveness and environmental sustainability. Cable insulation cut machines are engineered to optimize material usage, reducing off-cuts and excess insulation. This reduction not only lowers material costs but also fosters a more sustainable production process.

4. Versatility Most cable insulation cut machines can accommodate a wide range of cable types and sizes. This versatility makes them suitable for various applications, from small electronic devices to large industrial cables. As technology advances, new models are being developed to cater to the changing needs of the industry.

5. Enhanced Safety The automation of the cutting process significantly reduces the risks associated with manual labor. Workers are less likely to suffer injuries related to cutting tools and fatigue. Additionally, many modern machines come with safety features such as emergency stops and protective guards to enhance workplace safety further.

Technological Innovations

Recent advancements in technology have led to the development of sophisticated cable insulation cut machines that incorporate smart technology and automation. Features such as programmable interfaces, sensors, and data analytics facilitate real-time monitoring and adjustments, ensuring optimal performance. These innovations allow manufacturers to fine-tune their production processes and respond quickly to changing demands.

Conclusion

In conclusion, cable insulation cut machines are vital tools in the manufacturing industry. Their ability to enhance efficiency, precision, and safety while reducing waste makes them indispensable for businesses that rely on high-quality cable production. As technology continues to evolve, we can expect to see even more innovative solutions that further improve the capabilities and performance of cable insulation cut machines. Embracing this technology represents a strategic investment for manufacturers looking to maintain competitiveness in an increasingly demanding market.

-

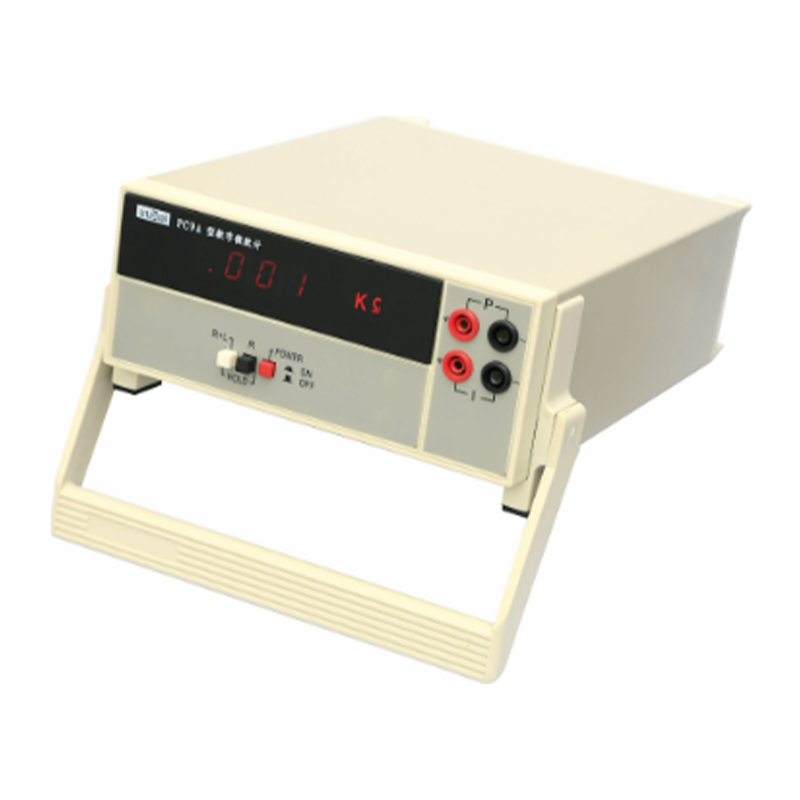

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy