custom cable flexibility test machine

Custom Cable Flexibility Test Machine Ensuring Quality and Reliability in Cable Manufacturing

In the modern era of technology, the demand for high-quality cables is ever-increasing. From telecommunications to medical devices, cables play a critical role in ensuring efficient operations across various industries. One of the paramount aspects of cable quality is its flexibility. When cables lack flexibility, they can fail prematurely, leading to costly downtimes and safety hazards. To address these concerns, the development of custom cable flexibility test machines has become essential for manufacturers.

Understanding Cable Flexibility

Cable flexibility refers to the ability of a cable to bend without breaking or sustaining damage. This property is crucial for applications where cables are frequently moved or subjected to bending. Factors influencing flexibility include the materials used in the construction of the cable, the design of the cable, and the overall thickness of its insulation.

Testing for flexibility ensures that cables can withstand real-world conditions, such as being coiled, twisted, or exposed to vibrations over extended periods. Implementing rigorous flexibility tests in the manufacturing process helps to identify weak points in cable design and material selection, ultimately leading to increased product reliability.

The Role of Custom Cable Flexibility Test Machines

Custom cable flexibility test machines are specialized equipment designed to evaluate the flexibility and durability of cables under various bending conditions. These machines can simulate different operational scenarios, providing manufacturers with critical data on how their products will perform in the field.

The versatility of these machines allows them to accommodate various cable types, from simple electrical wires to complex multi-conductor cables. They can be engineered to replicate specific movements and stresses, helping manufacturers understand how their cables respond under different conditions.

Key Features of Custom Test Machines

1. Adjustable Parameters Custom flexibility test machines often allow for the adjustment of parameters such as bending radius, speed of movement, and the number of cycles, making it easier for manufacturers to simulate real-life applications.

2. Data Logging and Analysis The machines come equipped with advanced sensors and data logging capabilities to record performance metrics. This data is essential for quality assurance and can help identify trends or potential failure points in the cable design.

custom cable flexibility test machine

3. Automated Testing Automation capabilities enable continuous testing without the need for constant human oversight. This not only improves efficiency but also ensures consistent testing conditions, thus enhancing the reliability of results.

4. User-Friendly Interfaces Modern machines typically feature intuitive interfaces that allow operators to easily set testing parameters, monitor progress, and review results. This ease of use is crucial for optimizing productivity in manufacturing environments.

5. Compliance with Standards Many custom cable flexibility test machines are designed to meet or exceed industry standards such as IEC and UL requirements. This ensures that the cables produced are not only flexible but also compliant with safety regulations.

Benefits of Implementing Custom Cable Flexibility Tests

Incorporating flexibility testing into the manufacturing process offers several benefits

- Improved Product Quality By identifying and rectifying flexibility issues early in the production process, manufacturers can significantly enhance the overall quality of their cables.

- Increased Customer Satisfaction Cables that are tested for flexibility are less likely to fail in the field, leading to higher customer satisfaction and trust in the brand.

- Cost Savings Reducing the rate of cable failures translates to lower warranty claims and maintenance costs, providing a significant return on investment for manufacturers.

- Innovation Continuous testing encourages innovation in cable design and materials, as manufacturers strive to create products that not only meet but exceed industry standards.

Conclusion

The importance of cable flexibility cannot be overstated in today’s high-demand environments. Custom cable flexibility test machines play an essential role in ensuring that manufacturers produce cables capable of performing reliably in real-world conditions. By investing in such testing technology, manufacturers can enhance product quality, ensure compliance with industry standards, and ultimately deliver better value to their customers. As technology continues to evolve, the significance of flexibility testing will undoubtedly grow, securing its place as a critical component in the cable manufacturing process.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

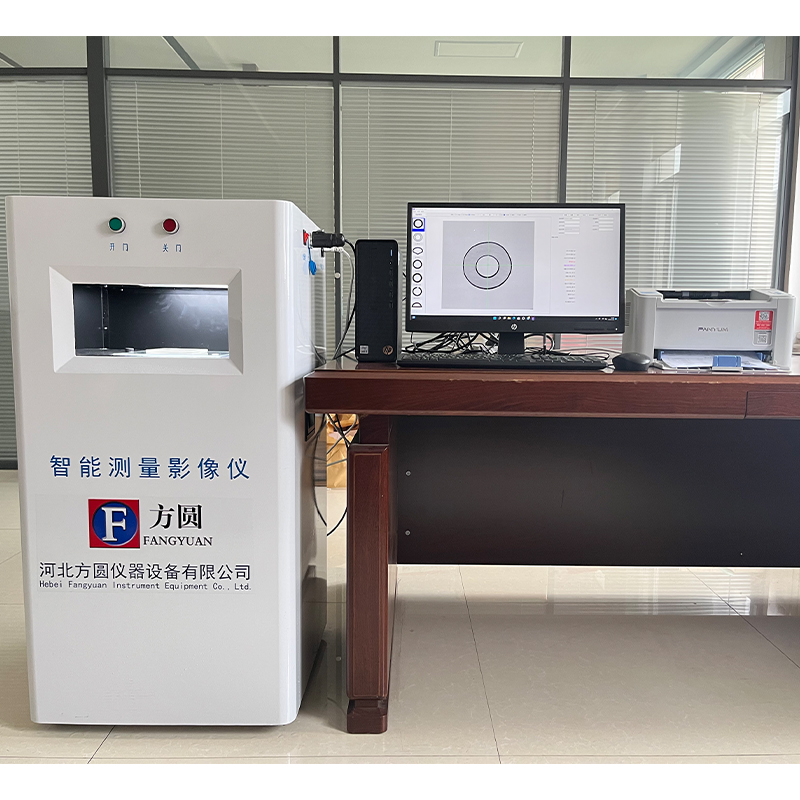

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy