Sau . 29, 2025 04:33

Back to list

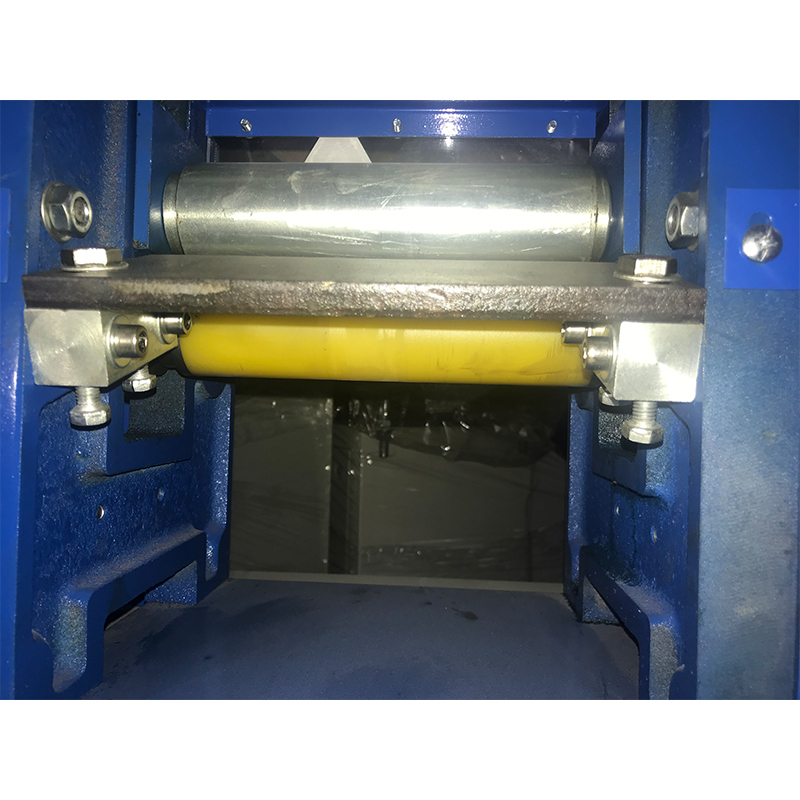

DQ-F Superfine Wire Conductor Resistance Fixture

When it comes to measuring mechanical properties of materials, few instruments offer the flexibility and precision of the custom universal tensile tester. This tool plays an essential role in quality assurance across various industries, ensuring that materials meet their specified standards before they reach the consumer. From aerospace and automotive to electronics and consumer goods, the import of a reliable tensile tester cannot be overstated.

While offering tremendous benefits, it is crucial that the use of such a tester adheres to international testing standards. Compliance with standards such as ASTM or ISO ensures that testing methods are globally recognized and that test results are universally accepted. This adherence not only boosts the manufacturer's authority in the global market but enhances consumer trust in their products. Maintenance and calibration of the equipment are pivotal to maintaining its reliability and accuracy over time. Regular servicing by certified technicians experienced in the nuances of tensile testers ensures that the equipment functions as intended. Calibration should be performed at scheduled intervals, as recommended by the manufacturer, to maintain the highest level of precision. In addressing trustworthiness, the selection of a reputable provider or manufacturer of tensile testers can make a considerable difference. Companies that prioritize transparency, customer support, and comprehensive training demonstrate their commitment to not just selling a product, but partnering with their customers for mutual success. Universal tensile testers are no longer a choice, but a necessity for competitive industries aiming for superiority in product quality and consistency. Through expert operation, adherence to standards, and consistent maintenance, these machines contribute significantly to the advancement of material sciences. They play an instrumental role in pushing the boundaries of innovation, reliability, and consumer trust in available materials. In conclusion, a custom universal tensile tester is not just an instrument of measurement but a cornerstone in the journey of material explorations and product integrity assurance. Its customization capabilities, coupled with the expert knowledge required for its operation, make it an invaluable asset in modern manufacturing and engineering environments. As industries face increasing pressure to enhance product performance, reduce waste, and ensure sustainability, investing in such indispensable tools becomes paramount.

While offering tremendous benefits, it is crucial that the use of such a tester adheres to international testing standards. Compliance with standards such as ASTM or ISO ensures that testing methods are globally recognized and that test results are universally accepted. This adherence not only boosts the manufacturer's authority in the global market but enhances consumer trust in their products. Maintenance and calibration of the equipment are pivotal to maintaining its reliability and accuracy over time. Regular servicing by certified technicians experienced in the nuances of tensile testers ensures that the equipment functions as intended. Calibration should be performed at scheduled intervals, as recommended by the manufacturer, to maintain the highest level of precision. In addressing trustworthiness, the selection of a reputable provider or manufacturer of tensile testers can make a considerable difference. Companies that prioritize transparency, customer support, and comprehensive training demonstrate their commitment to not just selling a product, but partnering with their customers for mutual success. Universal tensile testers are no longer a choice, but a necessity for competitive industries aiming for superiority in product quality and consistency. Through expert operation, adherence to standards, and consistent maintenance, these machines contribute significantly to the advancement of material sciences. They play an instrumental role in pushing the boundaries of innovation, reliability, and consumer trust in available materials. In conclusion, a custom universal tensile tester is not just an instrument of measurement but a cornerstone in the journey of material explorations and product integrity assurance. Its customization capabilities, coupled with the expert knowledge required for its operation, make it an invaluable asset in modern manufacturing and engineering environments. As industries face increasing pressure to enhance product performance, reduce waste, and ensure sustainability, investing in such indispensable tools becomes paramount.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy