Innovative Solutions for Tensile Testing Machines and Advanced Material Testing Equipment Providers

Understanding Tensile Testing Machines Key Players in Material Testing

In the field of material science and engineering, understanding the mechanical properties of materials is essential. One of the most critical tests for evaluating these properties is tensile testing, which measures how materials behave under tension. To perform tensile tests effectively, professionals rely on specialized equipment known as tensile testing machines. Various companies manufacture these machines, contributing significantly to quality control and research in various industries.

What is a Tensile Testing Machine?

A tensile testing machine, often referred to as a universal testing machine (UTM), is designed to test the tensile strength of materials by applying a controlled, uniaxial force until the material fails. The machine consists of several key components, including a load cell to measure force, grips to hold the sample, and an extensometer to measure elongation. As the test progresses, the machine records data on how much the material stretches or deforms under the applied load, enabling engineers and researchers to derive important material properties such as ultimate tensile strength, yield strength, and elongation percentage.

Importance of Tensile Testing

Tensile testing serves a multitude of purposes across various industries. In the automotive sector, for instance, understanding the tensile strength of metals and composites is crucial for ensuring safety and performance. In aerospace, tensile testing data helps in selecting materials that can withstand extreme conditions without failure. The construction industry also relies on these tests to guarantee that the materials used for buildings and infrastructure can handle the stresses they will encounter over time.

In addition to industrial applications, tensile testing plays a vital role in research and development. By studying how different materials respond to tensile forces, scientists can develop new alloys, plastics, and composite materials with improved properties. This research ultimately leads to innovations that enhance product durability, performance, and sustainability.

Leading Companies in Tensile Testing Equipment

tensile testing machine company

Several companies have established themselves as leaders in the tensile testing machine market

. These manufacturers invest heavily in technology and R&D to provide high-quality, reliable testing equipment.1. Instron Founded in the 1940s, Instron is a pioneer in materials testing equipment. They offer a wide range of tensile testing machines, known for their precision and user-friendly software. Instron's machines are commonly used in aerospace, automotive, and medical applications.

2. MTS Systems Corporation MTS specializes in advanced testing systems and services. Their tensile testing machines are widely used in both industrial and research settings. MTS machines are noted for their durability and accuracy, making them a favorite among material testing laboratories.

3. ZwickRoell This company is renowned for its extensive range of testing machines, including those for tensile testing. They are recognized for their innovative technology and commitment to customer satisfaction, with options tailored to various industries and research needs.

4. Shimadzu Corporation Based in Japan, Shimadzu offers versatile tensile testing machines known for their functionality and reliability. Their testing equipment integrates advanced data analysis features that assist engineers in making informed decisions based on material performance.

Conclusion

Tensile testing machines are indispensable tools in understanding and ensuring the reliability of materials across numerous industries. As technology continues to advance, these machines are becoming more sophisticated, enabling even greater precision and versatility in testing. Companies like Instron, MTS, ZwickRoell, and Shimadzu lead the way in developing equipment that not only meets current industry standards but also drives innovation in material science. Understanding the machinery and its applications not only facilitates better material selection but also enhances product safety and performance in a constantly evolving market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

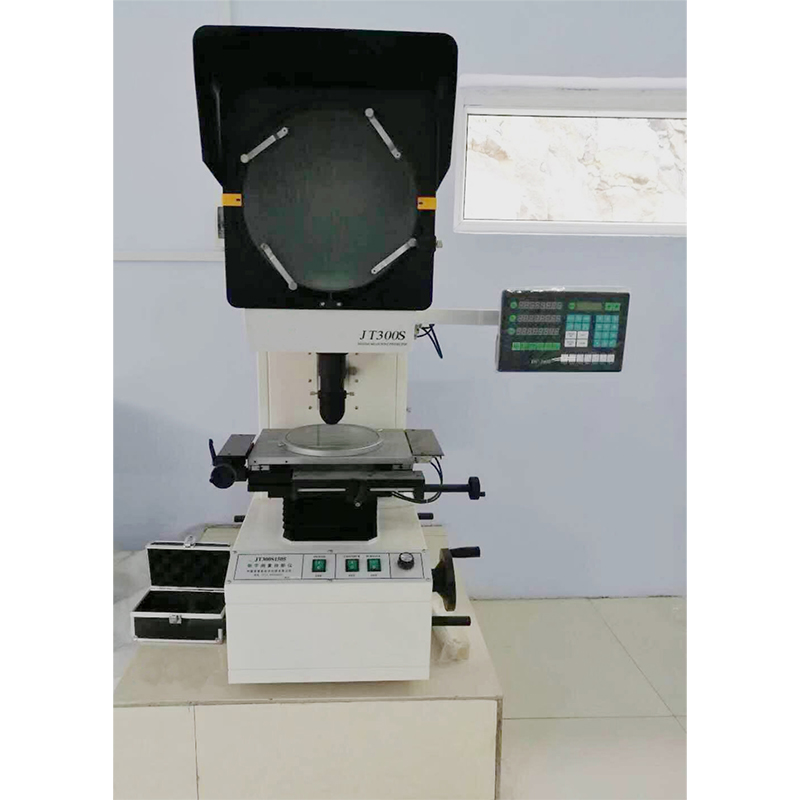

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy