wire reverse bending test machine suppliers

Understanding Wire Reverse Bending Test Machines Key Suppliers and Their Importance

In various industries, particularly in manufacturing and quality assurance, testing the mechanical properties of materials is crucial. One such method employed is the reverse bending test, which is designed to evaluate a wire's resistance to deformation and fatigue. The machines that conduct these tests are known as wire reverse bending test machines. This article aims to shed light on the function of these machines, the significance of selecting the right suppliers, and what to look for in reputable manufacturers.

The Function of Wire Reverse Bending Test Machines

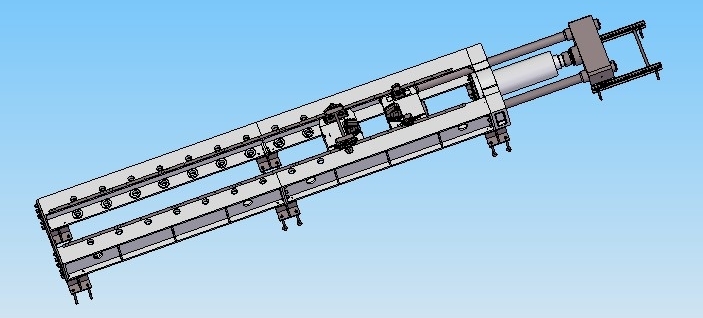

Wire reverse bending test machines are specialized devices used to simulate the conditions that wires or cables may encounter in real-world applications. During the test, a wire sample is bent back and forth over a predefined angle and radius, replicating the stress it may experience in situ. The main objective of this testing is to determine the wire's fatigue limit, tensile strength, and overall durability under repeated bending.

The results from these tests provide valuable insights into whether the wire can be relied upon for specific applications, especially in sectors like construction, automotive, and electronics. By assessing the mechanical properties of wires, manufacturers can ensure that their products meet industry standards and ultimately enhance the safety and performance of their applications.

Importance of Choosing the Right Suppliers

Choosing the right supplier for wire reverse bending test machines is imperative for the successful implementation of quality control processes. An ideal supplier should not only provide high-quality testing machines but also offer necessary support, including installation, maintenance, and training for operators.

Investing in a reliable machine from a reputable supplier can lead to long-term savings, as quality machines require less frequent repairs and replacements. Furthermore, a reputable supplier ensures compliance with industry standards and guarantees that the equipment can consistently produce accurate results.

wire reverse bending test machine suppliers

Key Features to Look for in Suppliers

1. Quality and Reliability The foremost factor to consider is the reliability of the machine. Quality brands often provide machines made with durable materials to withstand rigorous testing. Prospective buyers should inquire about the machine’s lifecycle and the materials used in its construction.

2. Technology and Innovation With advancements in technology, it’s essential to choose a supplier that incorporates the latest innovations in their machinery. Features like digital interfaces, automated testing cycles, and advanced data analysis capabilities can significantly enhance efficiency and accuracy.

3. Customer Support Excellent customer service is vital. Suppliers should offer ongoing technical support, training for new users, and help with machine calibration to ensure that their customers maximize the utility of the testing machines.

4. Customization Options Different industries may have unique requirements. Suppliers that offer customization options can cater to specific testing needs, ensuring that the equipment performs effectively in various environments.

5. Certification and Compliance Ensure that the supplier’s machines meet national and international standards. Certifications can indicate a supplier’s commitment to quality and performance, which can be critical for industries that require stringent compliance, such as aerospace and automotive.

Conclusion

In conclusion, wire reverse bending test machines play a vital role in quality assurance across multiple industries. The selection of the right supplier should not be taken lightly, as it can significantly influence the efficiency of testing processes and the overall reliability of wire products. By considering factors such as quality, technology, customer support, customization, and compliance, businesses can make informed decisions that ultimately lead to enhanced product performance and safety in their respective fields. Investing in quality testing machinery is not just a purchase; it is a commitment to excellence.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy