Јан . 15, 2025 05:00

Back to list

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

When considering advancements in cable insulation slicing machines, the fusion of cutting-edge technology and superior craftsmanship has catalyzed remarkable innovations. These machines, pivotal in industries such as electronics, telecommunications, and automotive, play a crucial role in ensuring the integrity and durability of power cables.

Moreover, regular feedback from industry professionals ensures that these machines evolve continuously, integrating the latest technological developments and methodologies. This approach not only reinforces the machine’s status as a leader in innovation but also fosters a trusting relationship with customers who rely on consistent advancements to meet their operational needs. The collaborative efforts between manufacturers and industry specialists further highlight the machine’s expertise and authority. By engaging with electrical engineers, safety inspectors, and automation experts, manufacturers ensure that each machine adheres to the latest international standards and guidelines. This adherence not only underscores the company's commitment to quality and safety but also boosts customer confidence, ensuring reliability and trust in every slice. Finally, proactive customer support and maintenance services extend this experience. Access to a dedicated support team and comprehensive maintenance plans assures customers that they have a dependable partner in maintaining operational efficiency. This consistent after-sale support epitomizes trustworthiness, ensuring that any issues are resolved swiftly and professionally, reducing downtime and optimizing productivity. In conclusion, for industries seeking a robust, reliable, and safe solution to cable insulation challenges, investing in a high-quality cable insulation slicing machine represents a sound strategic choice. Equipped with precision technology, expert implementation, and backed by authoritative support, these machines are not only tools but integral components in driving operational excellence and maintaining an edge in a competitive market.

Moreover, regular feedback from industry professionals ensures that these machines evolve continuously, integrating the latest technological developments and methodologies. This approach not only reinforces the machine’s status as a leader in innovation but also fosters a trusting relationship with customers who rely on consistent advancements to meet their operational needs. The collaborative efforts between manufacturers and industry specialists further highlight the machine’s expertise and authority. By engaging with electrical engineers, safety inspectors, and automation experts, manufacturers ensure that each machine adheres to the latest international standards and guidelines. This adherence not only underscores the company's commitment to quality and safety but also boosts customer confidence, ensuring reliability and trust in every slice. Finally, proactive customer support and maintenance services extend this experience. Access to a dedicated support team and comprehensive maintenance plans assures customers that they have a dependable partner in maintaining operational efficiency. This consistent after-sale support epitomizes trustworthiness, ensuring that any issues are resolved swiftly and professionally, reducing downtime and optimizing productivity. In conclusion, for industries seeking a robust, reliable, and safe solution to cable insulation challenges, investing in a high-quality cable insulation slicing machine represents a sound strategic choice. Equipped with precision technology, expert implementation, and backed by authoritative support, these machines are not only tools but integral components in driving operational excellence and maintaining an edge in a competitive market.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

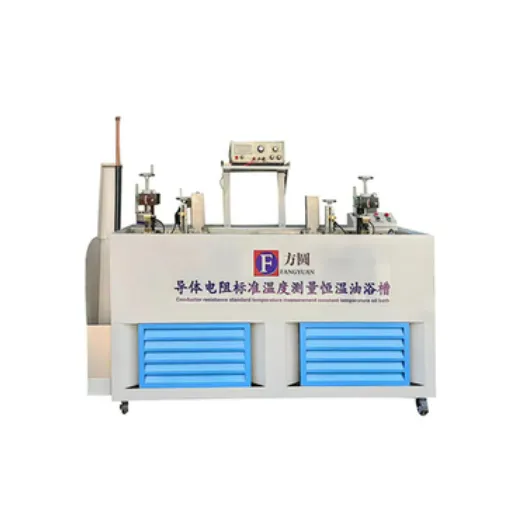

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy