tensile testers manufacturers

Understanding the Importance of Tensile Testers in Material Testing

In the realm of material testing, tensile testers play a crucial role in evaluating the mechanical properties of materials. These devices are instrumental in determining how materials behave under tension, providing essential data for engineers, researchers, and quality assurance professionals. This article explores the significance of tensile testers, the key manufacturers in the market, and the future trends in this critical field.

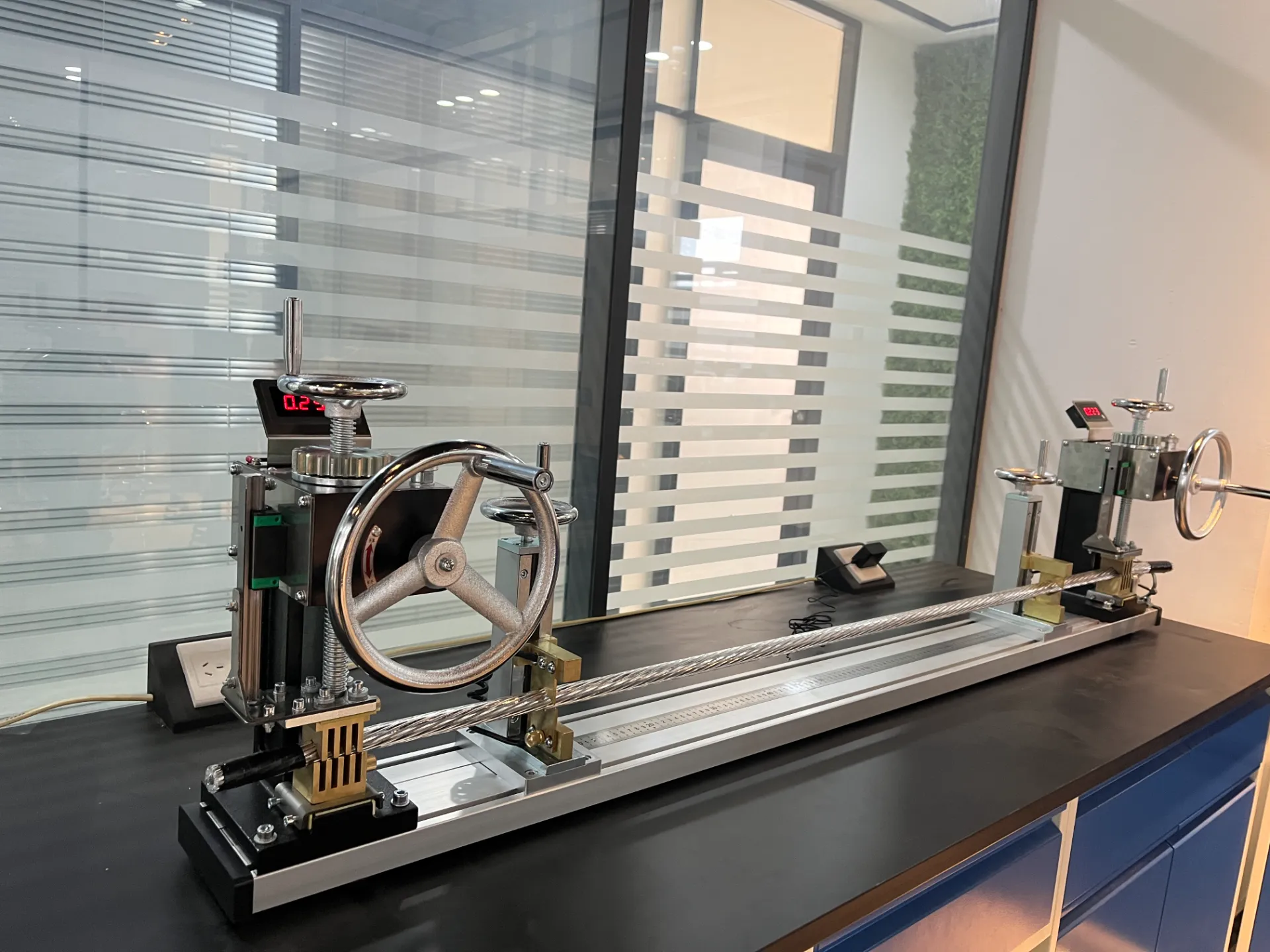

What is a Tensile Tester?

A tensile tester, also known as a universal testing machine (UTM), is specifically designed to apply axial loads to materials to assess their tensile strength, elongation, elasticity, and other mechanical properties. By applying a controlled force until the material fails, tensile testers provide precise measurements that help in understanding how materials will perform under various conditions. This is fundamental in industries such as construction, automotive, aerospace, and manufacturing, where material integrity is paramount.

Key Features of Tensile Testers

Modern tensile testers come equipped with advanced technology that enhances their functionality and accuracy. Key features include

1. Load Capacity Different materials require different load capacities. Manufacturers offer tensile testers tailored to accommodate a vast range of materials from soft plastics to tough metals.

2. Speed Control The ability to control the speed at which the load is applied is vital. Different materials react differently under varying strain rates, and precise speed control ensures accurate results.

3. Data Acquisition Systems Most contemporary tensile testers include sophisticated data acquisition systems that provide real-time feedback during testing. This allows operators to monitor performance and make adjustments if necessary.

4. Sample Holders The design of sample holders can significantly affect the accuracy of the tests. Quality manufacturers provide customizable grips and fixtures to ensure optimal performance based on the specific material being tested.

Leading Manufacturers of Tensile Testers

The market for tensile testers features several prominent manufacturers known for their commitment to quality and innovation. Some key players include

1. Instron A global leader in material testing equipment, Instron offers a wide range of tensile testers known for their precision and reliability. Their machines are widely used in various industries and are equipped with advanced data analysis capabilities.

tensile testers manufacturers

3. Shimadzu Corporation With a strong reputation for scientific equipment, Shimadzu produces tensile testers that are not only reliable but also compatible with various testing standards such as ASTM and ISO.

4. ZwickRoell This German company specializes in mechanical testing systems, including tensile testers that are recognized for their accuracy and ease of use. They offer a broad spectrum of applications across numerous industries.

5. Tinius Olsen A historic manufacturer of material testing machines, Tinius Olsen provides a range of tensile testing solutions known for their robustness and longevity.

The Future of Tensile Testing

As industries drive towards greater innovation, the tensile testing market is also evolving. Future trends include

1. Automation There is a growing trend towards automating the tensile testing process. Automated systems enhance throughput, reduce human error, and ensure repeatable test conditions.

2. Software Integration Advanced software for data analysis is becoming increasingly important. Integrating software that can predict material behavior and enhance reporting will be a game changer for engineers and manufacturers.

3. Sustainability As sustainability becomes a key focus across industries, tensile testers are being designed to evaluate recycled materials and environmentally-friendly composites, helping manufacturers meet new regulatory requirements.

4. Miniaturization With the rise of micro-electronics and nano-materials, there is a demand for miniaturized testing systems that can accurately assess small samples while maintaining precision.

Conclusion

Tensile testers are indispensable tools in the material testing landscape. They provide critical data that informs product design, quality control, and safety compliance. Understanding the features and applications of these machines, as well as the premier manufacturers in the field, is essential for professionals aiming to select the right equipment for their needs. As technology continues to advance, the evolution of tensile testing will undoubtedly lead to more accurate, efficient, and sustainable practices in material science.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy