cable repeated bending tester companies

The Importance of Cable Repeated Bending Testers in Quality Control

In our modern world, the demand for reliable and durable cables is ever increasing. Cables are integral to a vast array of applications, from telecommunications and power distribution to consumer electronics and automotive systems. As technology advances and devices become more sophisticated, the need for high-quality cables that can withstand repeated use and environmental stresses has become paramount. This is where cable repeated bending testers come into play.

What Are Cable Repeated Bending Testers?

Cable repeated bending testers are specialized machines designed to simulate the stresses that cables endure in real-world applications. These testers repeatedly bend and flex cables at specific angles and frequencies to assess their durability and performance over time. The testing process helps manufacturers identify potential weaknesses in their products, ensuring that only high-quality cables reach consumers.

The Importance of Testing

Why is such testing critical? Cables are often subject to numerous factors that can compromise their integrity. For instance, cables in mobile devices may be flexed thousands of times a day, while those in automotive applications face vibrations and environmental factors. Testing cables with repeated bending ensures they can withstand these challenges without breaking or degrading.

Adopting a rigorous testing regimen can help companies avoid product failures, enhance customer satisfaction, and reduce costs associated with warranty claims and product recalls. In industries where safety is paramount, such as aerospace and medical devices, reliable cables are non-negotiable.

Leading Companies in Cable Testing Equipment

Several companies worldwide specialize in manufacturing cable repeated bending testers, each offering various features and specifications designed to meet the needs of different industries.

1. Instron – A leading provider of materials testing equipment, Instron offers advanced testing solutions, including bending testers that can simulate various environmental conditions. Their equipment is known for precision and reliability, making it a popular choice among manufacturers.

cable repeated bending tester companies

2. QM Testing Equipment – This company focuses on providing cost-effective testing machines that meet international standards. QM Testing Equipment’s cable bending testers are designed for efficient testing without compromising accuracy.

3. Advanced Test Equipment Corporation (ATEC) – ATEC's testers are highly customizable, allowing clients to tailor specifications to their needs. Their devices often integrate cutting-edge technology, offering real-time data analysis and reporting features.

4. Mitutoyo – Known for its measurement and inspection equipment, Mitutoyo features cable bending testers that ensure high precision and conformity with industry standards. Their products are widely used across multiple sectors for quality assurance.

5. Universal Testing Machines – They provide comprehensive testing solutions, including cable bending testers that boast a user-friendly interface and help manufacturers conduct tests with ease and accuracy.

Choosing the Right Tester

When selecting a cable repeated bending tester, companies should consider several factors

- Testing Standards Ensure the equipment complies with industry standards (e.g., IEC, UL) relevant to your specific application. - Customization Options The ability to customize settings and parameters can be beneficial for meeting unique testing requirements. - Data Reporting Look for machines that provide detailed reporting functionalities to analyze results effectively. - User-friendliness An intuitive interface can reduce training time and improve operational efficiency. - Service and Support Opt for a vendor that offers robust customer service and support for maintenance and troubleshooting.

Conclusion

Cable repeated bending testers are indispensable tools in the pursuit of cable durability and quality assurance. As industries move towards more advanced technologies, the importance of reliable electrical connections cannot be overstated. By investing in high-quality testing equipment, companies can ensure their products meet stringent quality standards, leading to enhanced safety, performance, and customer satisfaction. The evolving landscape of technology will continue to put pressure on manufacturers to deliver greater reliability, and those who embrace rigorous testing methodologies will undoubtedly thrive in today's competitive market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

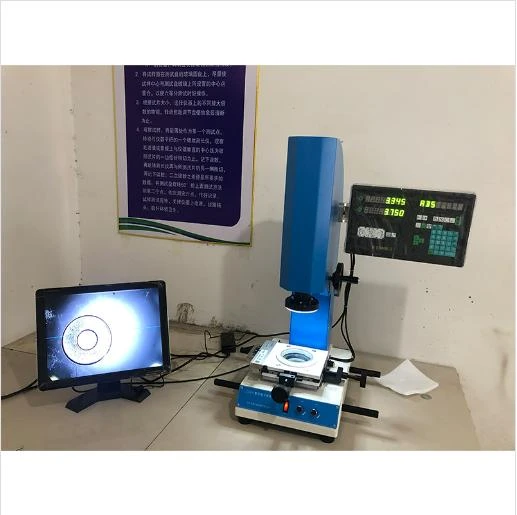

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy