Custom Conductor Resistance Measurement System for Constant Temperature Applications

The Importance of Custom Conductor Resistance Testing at Constant Temperature

In the ever-evolving fields of electronics and electrical engineering, understanding the properties of conductors is essential for the design and performance of high-quality electrical systems. One critical parameter for assessing conductor performance is resistance. This article will discuss the significance of custom conductor resistance testing at a constant temperature and its implications for reliability, efficiency, and safety in electrical applications.

Understanding Conductor Resistance

The resistance of a conductor is a direct measure of how much it opposes the flow of electric current. It is determined by various factors, including the material type, cross-sectional area, temperature, and the length of the conductor. For practical applications, especially in power distribution and electronic circuits, it is vital to ensure that the resistance remains within acceptable limits to avoid excessive energy losses and overheating.

The Role of Temperature in Resistance

Resistance in conductors is highly temperature-dependent. According to the equation \( R(T) = R_0(1 + \alpha(T - T_0)) \), where \( R(T) \) is the resistance at temperature \( T \), \( R_0 \) is the resistance at a reference temperature \( T_0 \), and \( \alpha \) is the temperature coefficient of resistance for the material. This relationship highlights that as temperature increases, resistance generally increases for most conductive materials. Consequently, fluctuations in operating temperatures can significantly affect the accuracy of resistance measurements and, therefore, the performance of electrical systems.

Custom Testing Solutions

Given the importance of accurate resistance measurements, custom testing solutions are increasingly gaining traction in the industry. A custom conductor resistance tester enables engineers and technicians to evaluate conductive materials under specific conditions that match real-world applications. This allows for the assessment of conductor performance under various scenarios, ensuring durability and reliability.

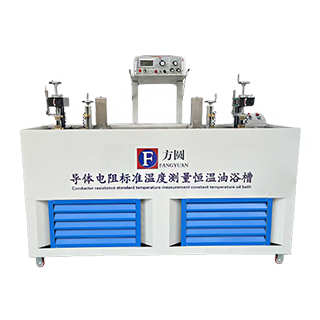

custom conductor resistance constant temperature tester

One significant advantage of custom testing is the ability to maintain a constant temperature during resistance measurements. By controlling the temperature, testing professionals can eliminate temperature-induced variability in resistance readings, thus obtaining more precise and consistent data. This ensures that the assessment reflects the true performance of the conductor in its intended application, whether in high-temperature industrial settings or in low-temperature environments like aerospace.

Implications for Reliability and Safety

Ensuring accurate resistance measurements through custom testing has profound implications for the reliability and safety of electrical systems. High resistance levels can lead to increased heat generation, resulting in potential failure of electronic components or conductor materials. In extreme cases, this can lead to system malfunctions or catastrophic failures, including electrical fires. By employing custom resistance testers, engineers can identify components with unacceptable resistance levels before they are deployed, significantly reducing the risk of failure.

Enhancing Efficiency

In addition to safety, accurate resistance measurement contributes to improved efficiency. Lower resistance values result in less energy wasted as heat, enhancing the overall performance of electrical systems. This is particularly crucial in high-performance applications, such as electric vehicles and renewable energy systems, where efficiency directly translates to lower operational costs and extended system lifetimes. By ensuring that conductors meet specification requirements through meticulous testing, engineers can optimize system designs for peak performance.

Conclusion

The significance of custom conductor resistance testing at constant temperature cannot be overstated. It not only facilitates accurate and reliable resistance measurements but also enhances safety and efficiency across various electrical applications. As technology continues to advance, the demand for precise testing solutions will likely grow, emphasizing the need for innovation in testing methodologies. By prioritizing accurate conductor resistance assessments, engineers can ensure the reliability and performance of electrical systems in a rapidly changing technological landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy