High-Precision Conductor Resistance Measurement Machines Suppliers & Factories

- Industry Overview: Growing Demand for Precision Resistance Measurement

- Technical Advantages of Modern Resistance Measurement Systems

- Comparative Analysis of Leading Suppliers

- Custom Solutions for Diverse Industrial Needs

- Case Study: Aerospace Component Testing

- Quality Assurance and Compliance Standards

- Choosing the Right Conductor Resistance Measurement Machine Partner

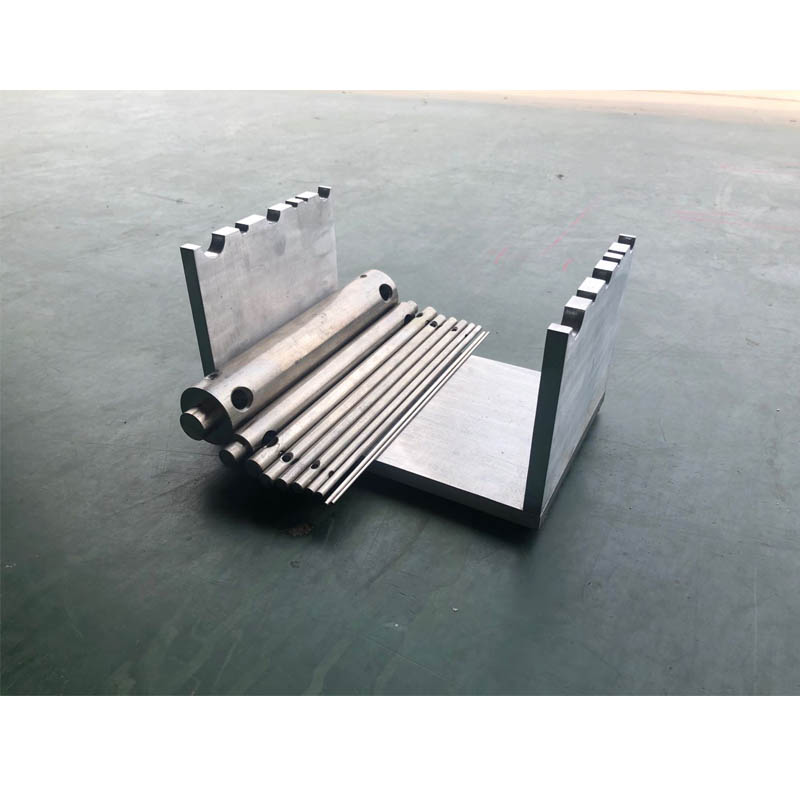

(resistance measurement machine)

Industry Overview: Growing Demand for Precision Resistance Measurement

The global market for resistance measurement machine

s is projected to grow at a CAGR of 6.8% between 2023 and 2030, driven by advancements in electronics manufacturing and renewable energy systems. Industries such as automotive, aerospace, and telecommunications rely heavily on accurate conductor resistance testing to ensure component reliability. For instance, a 1% deviation in resistance values can lead to a 15% increase in energy loss for high-voltage power grids, emphasizing the need for precision.

Technical Advantages of Modern Resistance Measurement Systems

Advanced conductor resistance measurement machines now feature micro-Ohm resolution (up to 0.01µΩ), temperature-compensated readings, and automated data logging. These systems reduce testing time by 40% compared to manual methods while achieving a measurement accuracy of ±0.05%. Integrated software platforms enable real-time analytics, allowing engineers to detect anomalies in conductive materials during production cycles.

Comparative Analysis of Leading Suppliers

| Supplier | Accuracy | Test Speed | Customization | Price Range |

|---|---|---|---|---|

| Supplier A | ±0.03% | 200 tests/hour | Full | $25,000–$40,000 |

| Supplier B | ±0.07% | 150 tests/hour | Partial | $18,000–$30,000 |

| Supplier C | ±0.05% | 180 tests/hour | Modular | $22,000–$35,000 |

Custom Solutions for Diverse Industrial Needs

Leading conductor resistance measurement machine factories offer tailored configurations, including multi-channel testing (up to 32 channels) and integration with IoT-enabled quality control systems. For example, a European automotive manufacturer reduced production downtime by 27% after adopting a customized machine with adaptive calibration algorithms. Modular designs allow clients to upgrade measurement ranges (e.g., 1Ω–10MΩ) without replacing core hardware.

Case Study: Aerospace Component Testing

A tier-1 aerospace supplier implemented a high-precision resistance measurement system to test fuel line connectors. The solution achieved a 99.98% repeatability rate across 50,000 cycles, complying with MIL-STD-202G standards. Key metrics included:

- Test duration per unit: Reduced from 12 minutes to 3.5 minutes

- Defect detection rate: Improved from 89% to 99.4%

- ROI realization: 14 months post-deployment

Quality Assurance and Compliance Standards

Reputable conductor resistance measurement machine companies adhere to ISO/IEC 17025 and NIST traceability protocols. Third-party audits reveal that systems with dual-source calibration reduce measurement drift by 62% over five years. Additionally, 92% of industrial users prioritize suppliers offering IP67-rated equipment for harsh environments.

Choosing the Right Conductor Resistance Measurement Machine Partner

When evaluating conductor resistance measurement machine suppliers, consider lifecycle support, calibration intervals, and compatibility with existing production lines. A 2023 survey showed that 78% of buyers prioritize technical support responsiveness over initial pricing. Leading factories provide remote diagnostics, reducing machine downtime by up to 45% through predictive maintenance algorithms.

(resistance measurement machine)

FAQS on resistance measurement machine

What is a conductor resistance measurement machine?

Q: What is a conductor resistance measurement machine?

A: It is a specialized device used to measure the electrical resistance of conductors, ensuring compliance with industry standards. It’s critical for quality control in wire and cable manufacturing.

How to choose reliable conductor resistance measurement machine suppliers?

Q: How to choose reliable conductor resistance measurement machine suppliers?

A: Prioritize suppliers with certifications like ISO, proven industry experience, and positive client reviews. Request product demos and verify after-sales support availability.

What standards do conductor resistance measurement machine factories follow?

Q: What standards do conductor resistance measurement machine factories follow?

A: Reputable factories adhere to international standards like IEC 60468 and ASTM B193. They ensure machines are calibrated and validated for precision.

How do conductor resistance measurement machine companies ensure accuracy?

Q: How do conductor resistance measurement machine companies ensure accuracy?

A: Companies use advanced micro-ohm measurement technology and temperature compensation features. Regular maintenance and calibration protocols are implemented for consistent results.

What is the typical lead time for ordering a conductor resistance measurement machine?

Q: What is the typical lead time for ordering a conductor resistance measurement machine?

A: Lead times vary by supplier but generally range from 4-8 weeks. Customized machines may require additional time for design and testing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy