ഫെബ്രു . 17, 2025 19:56

Back to list

cable smoke density test machine company

Smoke density chamber testing is an integral process within industries that manufacture products ranging from building materials to consumer electronics. These tests are pivotal for determining how products react under exposure to smoke, subsequently influencing safety standards and compliance with regulatory frameworks. While several factories worldwide offer smoke density testing, selecting the right facility demands careful consideration of several factors rooted in Experience, Expertise, Authoritativeness, and Trustworthiness.

Authoritativeness in the context of smoke density chamber test factories pertains to the recognition and accreditation from reputable industry bodies. International standards such as ISO 17025 for testing and calibration laboratories are a hallmark of a factory's reliability. Such accreditations are not merely a badge of honor but serve as a testament to the factory's adherence to stringent operational standards. Factories that possess these credentials are often sought after by manufacturers keen on aligning with globally recognized safety and quality benchmarks. Finally, Trustworthiness in selecting a smoke density testing factory is about building a relationship founded on transparency and integrity. Reputable factories maintain open channels of communication with their clients, offering detailed reports and insights that are devoid of technical jargon, thus ensuring comprehensive understanding and informed decision-making. Moreover, these factories prioritize customer confidentiality and data protection, recognizing the competitive nature of product development and the need to safeguard proprietary information. In conclusion, the process of selecting a smoke density chamber test factory is multi-faceted, requiring a keen evaluation against Experience, Expertise, Authoritativeness, and Trustworthiness. Manufacturers are encouraged to conduct thorough research and perhaps even visit potential testing facilities to witness their operational standards firsthand. By doing so, they ensure that the safety, compliance, and quality of their products are in capable hands, facilitating consumer trust and market success. Ultimately, the right choice of testing partner not only influences product certification but also reflects a brand’s commitment to upholding the highest standards of safety and quality in an ever-evolving industrial landscape.

Authoritativeness in the context of smoke density chamber test factories pertains to the recognition and accreditation from reputable industry bodies. International standards such as ISO 17025 for testing and calibration laboratories are a hallmark of a factory's reliability. Such accreditations are not merely a badge of honor but serve as a testament to the factory's adherence to stringent operational standards. Factories that possess these credentials are often sought after by manufacturers keen on aligning with globally recognized safety and quality benchmarks. Finally, Trustworthiness in selecting a smoke density testing factory is about building a relationship founded on transparency and integrity. Reputable factories maintain open channels of communication with their clients, offering detailed reports and insights that are devoid of technical jargon, thus ensuring comprehensive understanding and informed decision-making. Moreover, these factories prioritize customer confidentiality and data protection, recognizing the competitive nature of product development and the need to safeguard proprietary information. In conclusion, the process of selecting a smoke density chamber test factory is multi-faceted, requiring a keen evaluation against Experience, Expertise, Authoritativeness, and Trustworthiness. Manufacturers are encouraged to conduct thorough research and perhaps even visit potential testing facilities to witness their operational standards firsthand. By doing so, they ensure that the safety, compliance, and quality of their products are in capable hands, facilitating consumer trust and market success. Ultimately, the right choice of testing partner not only influences product certification but also reflects a brand’s commitment to upholding the highest standards of safety and quality in an ever-evolving industrial landscape.

Latest news

-

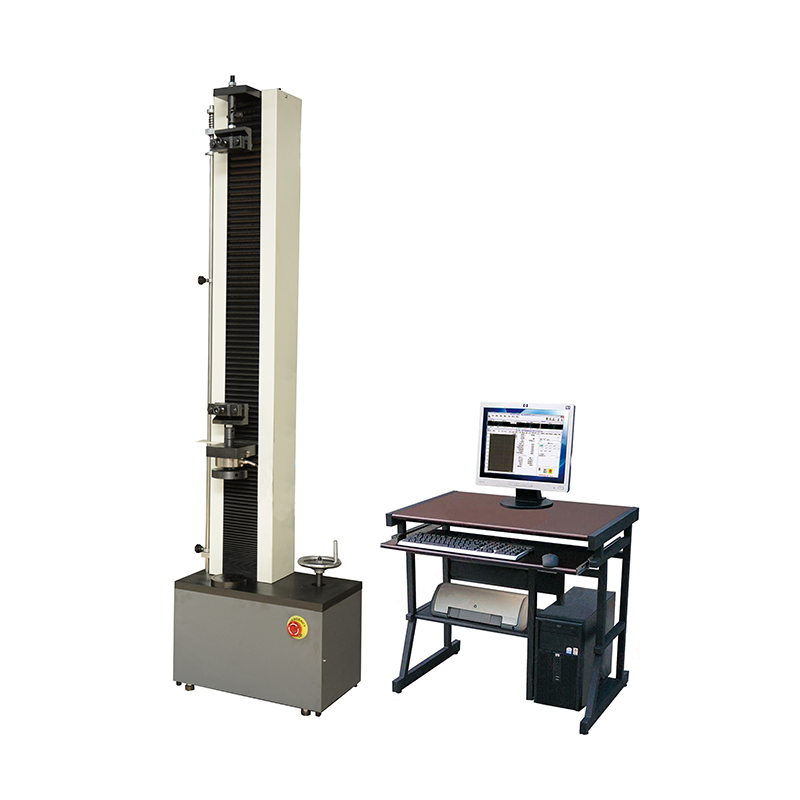

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy