UV-Curing Equipment Manufacturers for Efficient Crosslinking Solutions

Understanding UV Irradiation Crosslinking Machines Manufacturers and Their Impact

In the field of industrial processing, UV irradiation crosslinking machines have become pivotal for various applications, particularly in the curing of coatings, adhesives, and inks. This innovative technology utilizes ultraviolet (UV) light to induce chemical crosslinking in polymers, resulting in enhanced durability and performance of the final product. As industries continue to seek more efficient and environmentally friendly solutions, the role of manufacturers specializing in UV irradiation crosslinking systems has become increasingly significant.

The Significance of UV Irradiation Crosslinking

UV crosslinking technology offers numerous advantages over conventional curing methods. One of the primary benefits is its ability to cure materials at room temperature, eliminating the need for high heat that can sometimes compromise the integrity of sensitive substrates. Additionally, UV curing is a fast process which can significantly reduce production times, enhancing overall operational efficiency. This is particularly advantageous in high-volume manufacturing settings, where time-to-market is crucial.

Another important aspect is the reduced emissions of volatile organic compounds (VOCs) during the curing process. Traditional solvent-based systems often release significant amounts of VOCs, which can lead to environmental and health concerns. In contrast, UV curing systems provide a more sustainable option, aligning with global trends towards eco-friendly manufacturing processes.

Key Features of UV Crosslinking Machines

Modern UV irradiation crosslinking machines are equipped with advanced features designed to optimize production efficiency and ensure high-quality results. Key characteristics include

1. Variable UV Spectrum Many machines offer adjustable UV spectra to accommodate various materials and formulations. This flexibility allows manufacturers to tailor the curing process based on specific product requirements.

2. High-intensity UV Sources Manufacturers utilize powerful UV lamps (such as mercury vapor or LED sources) to achieve quicker curing times while ensuring uniform energy distribution across the material's surface.

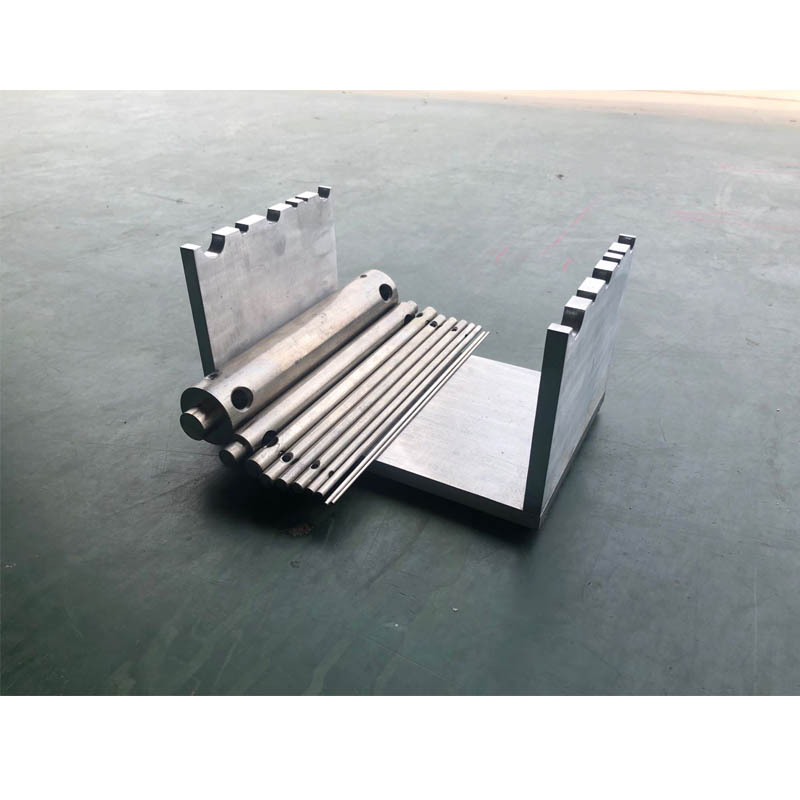

uv irradiation crosslinking machine manufacturer

3. Automated Systems Advanced automation features include conveyor belts, sensors, and control systems that monitor and adjust curing parameters in real-time. This not only enhances precision but also reduces the risk of human error.

4. Safety Measures Given the potential hazards associated with UV exposure, modern machines are often designed with integrated safety systems, such as shielding and interlocks, to protect operators.

Leading Manufacturers in the Industry

When it comes to UV irradiation crosslinking machines, several manufacturers have established themselves as industry leaders. Companies like Heraeus, Nordson, and ProntoPro are recognized for their innovative technology and commitment to quality. These manufacturers not only produce machines but also provide comprehensive support, including equipment installation, maintenance, and training.

Moreover, many of these companies are investing in research and development to continuously enhance their products. This innovation has led to the emergence of hybrid systems that combine UV curing with other technologies, such as electron beam curing, to further expand the capabilities of crosslinking applications.

Choosing the Right Manufacturer

Selecting the right UV irradiation crosslinking machine manufacturer is crucial for businesses aiming to implement or upgrade their curing processes. Key factors to consider include the manufacturer’s reputation, customer reviews, and the range of support services offered. Additionally, potential customers should evaluate the specific features of the machines, focusing on compatibility with their unique production needs.

Conclusion

UV irradiation crosslinking machines are at the forefront of modern manufacturing, delivering benefits in terms of efficiency, quality, and environmental sustainability. As industries evolve to meet regulatory demands and consumer expectations, the importance of reliable manufacturers in this field will only grow. By investing in advanced UV curing technology, businesses can not only enhance their product offerings but also contribute to a more sustainable future.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy