Suppliers of 50 Ton Tensile Testing Machines for Quality Assurance and Material Testing

Understanding 50% 20 Ton Tensile Tester Suppliers

When it comes to material testing, particularly in assessing tensile strength and behavior, a reliable tensile tester is essential. Among the various offerings in the industry, the 50% 20 ton tensile tester stands out as a significant tool for both manufacturers and quality control laboratories. This article delves into the importance of tensile testing, the features of a 50% 20 ton tensile tester, and how to choose the right suppliers for these essential instruments.

The Importance of Tensile Testing

Tensile testing is a fundamental procedure used to determine a material's mechanical properties, including strength, elongation, and ductility. The results from tensile tests guide engineers and manufacturers in product development, quality assurance, and compliance with industry standards. By applying a controlled load to a material sample, tensile testers evaluate how materials react under tension until they break.

The need for precise and high-capacity tensile testers, such as the 50% 20 ton models, arises in industries that work with high-strength materials, including construction, aerospace, automotive, and manufacturing. These industries require dependable data to ensure that materials can withstand specified loads, which is crucial for safety and performance.

Features of a 50% 20 Ton Tensile Tester

The designation 50% 20 ton refers to a tensile tester capable of applying a maximum load of 20 tons and providing accurate readings for materials that may not exceed 50% of that capacity. This dual-purpose capability allows for flexibility in testing various materials ranging from metals to plastics and composites.

Key features to look for in a 50% 20 ton tensile tester include

1. High Precision Measurements The tester should be equipped with advanced load cells and sensors to provide accurate and consistent readings. 2. User-Friendly Interface A digital display and intuitive controls can significantly enhance the user experience, making it easier for operators to set up tests and interpret results.

3. Data Logging and Analysis The ability to record and analyze tensile test results over time is crucial for quality control. Some testers come with software that allows users to visualize stress-strain curves and conduct further analysis.

4. Safety Features Given the high loads involved, safety mechanisms such as overload protection and emergency stop buttons are essential to ensure safe operation.

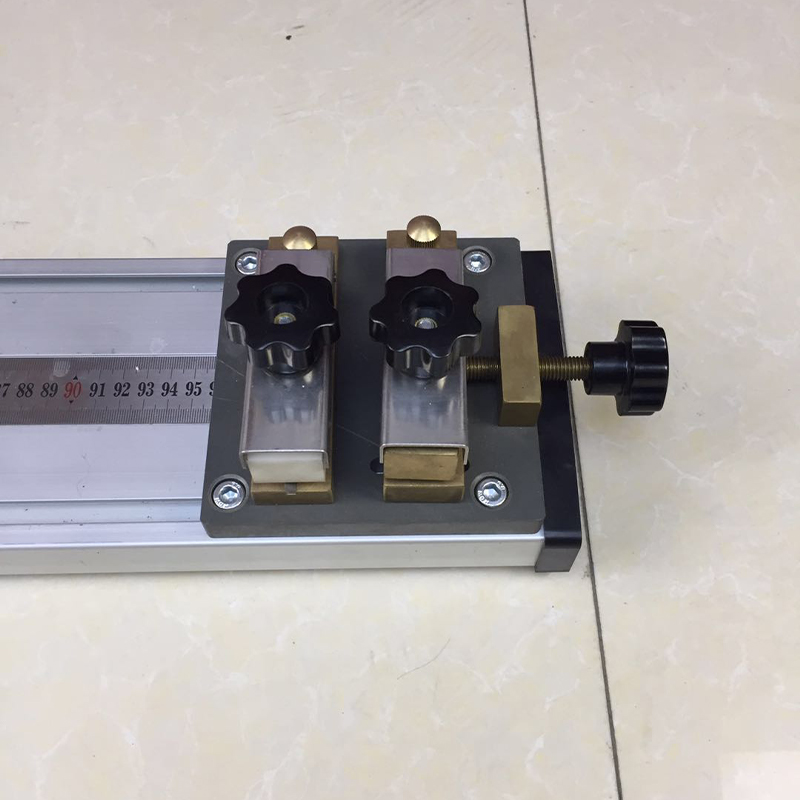

50 ton tensile tester suppliers

5. Versatility The tester should accommodate a range of specimen types and sizes to cater to diverse testing requirements. Interchangeable grips or fixtures may be a valuable addition.

Choosing the Right Suppliers

When selecting a supplier for a 50% 20 ton tensile tester, several factors must be considered

1. Reputation and Experience Look for suppliers that have established a reputation for quality and reliability in the material testing industry. A proven track record can provide peace of mind regarding product quality and service.

2. Support and Service Supplier support is crucial, especially for businesses that rely on consistent machine operation. Ensure that the supplier offers comprehensive customer service, including installation, training, and maintenance services.

3. Customization Options Depending on your specific testing needs, you may require customized solutions. Good suppliers should be willing to work with you to develop tailored solutions that fit your requirements.

4. Warranty and After-Sales Support A clear warranty policy and reliable after-sales support are crucial indicators of a reputable supplier. This can significantly reduce downtime and costs in the event of equipment failure.

5. Competitive Pricing While price should not be the sole deciding factor, obtaining quotes from multiple suppliers can help ensure you get a fair deal for quality testing equipment.

Conclusion

In the world of material testing, the importance of selecting the right tensile tester cannot be overstated. A 50% 20 ton tensile tester is an essential instrument for industries that prioritize quality assurance and compliance with safety standards. By understanding the key features of these testers and carefully choosing suppliers based on reputation, support, and customization capabilities, businesses can ensure they invest in reliable tools that will serve their testing needs for years to come. Whether for research or production, having the right tensile tester can make a significant difference in product quality and performance.

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy