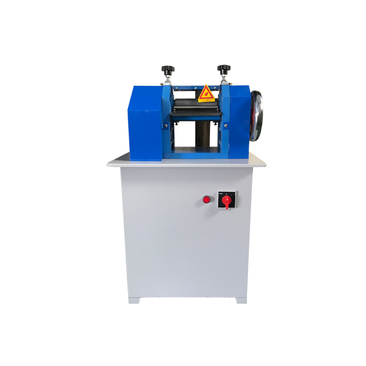

cable torsion testing machine exporter

The Role of Cable Torsion Testing Machines in Quality Control

In the modern manufacturing landscape, the quality and reliability of cable products are paramount. As industries ranging from telecommunications to automotive continue to evolve, the demand for high-performance cables has surged. To ensure that these cables meet stringent quality standards, manufacturers are increasingly relying on sophisticated testing equipment, among which the cable torsion testing machine plays a crucial role.

The Role of Cable Torsion Testing Machines in Quality Control

The process of torsion testing involves clamping one end of the cable while rotating the other end at a controlled speed. The machine records crucial data, such as torsional strength, elongation, and the point of failure. These metrics help manufacturers identify potential weaknesses in their products and make necessary adjustments to improve durability and performance. By simulating real-world conditions, cable torsion testing machines provide valuable insights that can lead to enhanced product designs and increased customer satisfaction.

cable torsion testing machine exporter

The export market for cable torsion testing machines is burgeoning as manufacturers across the globe seek to adopt advanced testing methodologies. Companies that specialize in producing these machines are poised for growth, as they cater not only to local markets but also to international clients in need of reliable testing solutions. Exporters must ensure that their machines comply with international standards and regulations, ensuring compatibility and reliability for users in various regions.

Furthermore, the rise of automated testing solutions is revolutionizing the industry. Many modern cable torsion testing machines come equipped with advanced data analysis software, enabling users to track performance metrics in real-time and generate comprehensive reports. This level of automation not only streamlines the testing process but also allows for greater precision and accuracy in results, drastically reducing the time needed for quality assurance.

In conclusion, cable torsion testing machines are indispensable in the quest for high-quality cable products. They provide manufacturers with the tools necessary to ensure their cables can withstand the rigors of their intended applications. As the demand for reliable cables grows, so will the importance of advanced testing equipment in maintaining industry standards and meeting customer expectations. For exporters of these machines, the future looks promising as they cater to an ever-expanding global market seeking quality assurance solutions.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy