calibrate insulation resistance tester exporters

Understanding the Calibration of Insulation Resistance Testers A Guide for Exporters

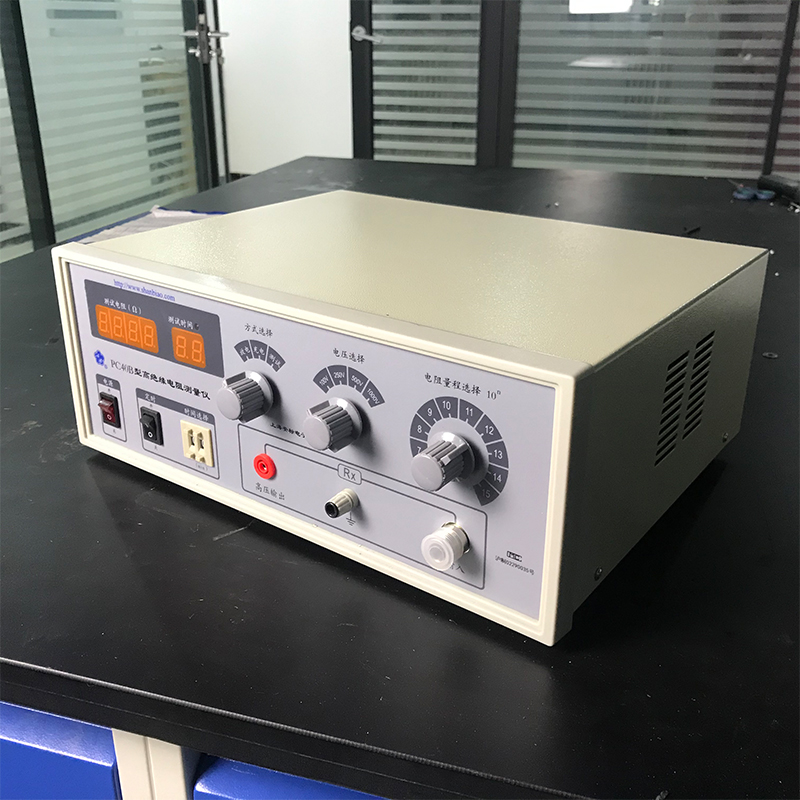

In the field of electrical testing, insulation resistance testers play a crucial role in ensuring the safety and reliability of electrical systems. These instruments measure the resistance of insulating materials, helping to identify potential faults and prevent electrical failures. As global demand for quality assurance rises, the need for calibrated insulation resistance testers has become increasingly important for exporters in this sector.

Calibration is the process of configuring an instrument to provide a result for a sample within an acceptable range. In the case of insulation resistance testers, consistent and accurate measurements are vital. Incorrect readings can lead to improper assessments of electrical systems, potentially resulting in equipment failure or safety hazards. Therefore, exporters must ensure their testers are calibrated according to industry standards to maintain their market credibility.

For exporters in this field, understanding the calibration process is essential. Calibration typically involves comparing the reading of an insulation resistance tester against a known standard. This ensures that the instrument's measurements are accurate and reliable. Many exporters utilize calibration services from accredited laboratories, which provide certification of conformity to international standards such as IEC (International Electrotechnical Commission) guidelines.

calibrate insulation resistance tester exporters

Additionally, regular calibration is essential to maintain accuracy over time. Environmental factors, such as temperature and humidity, can affect the performance of insulation resistance testers. Exporters should establish a calibration schedule that aligns with their operational requirements to minimize the risks associated with inaccurate readings. This proactive approach not only enhances the performance of their instruments but also fosters trust among clients and stakeholders.

Moreover, exporters must also be aware of the trends and advancements in testing technology. The market is evolving, with many manufacturers integrating digital technologies and smart features into insulation resistance testers. This innovation emphasizes the importance of compatible calibration techniques that can keep pace with these technical advancements.

In conclusion, the calibration of insulation resistance testers is a critical aspect that exporters must prioritize. By ensuring that their instruments are regularly calibrated and compliant with industry standards, exporters can enhance the reliability of their products, meet market demands, and ensure the safety of electrical systems. This commitment to quality not only strengthens the exporter’s reputation but also contributes significantly to global safety in electrical installations.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy