china wire and cable testing machine

The Importance of Wire and Cable Testing Machines in China

In an era where electrical and electronic devices are integral to our daily lives, ensuring the safety and reliability of these components is paramount. Among the many practices employed to guarantee quality, wire and cable testing emerges as a critical component, especially in a manufacturing powerhouse like China. The demand for wire and cable testing machines has surged as industries recognize the importance of adhering to stringent quality standards.

Understanding Wire and Cable Testing Machines

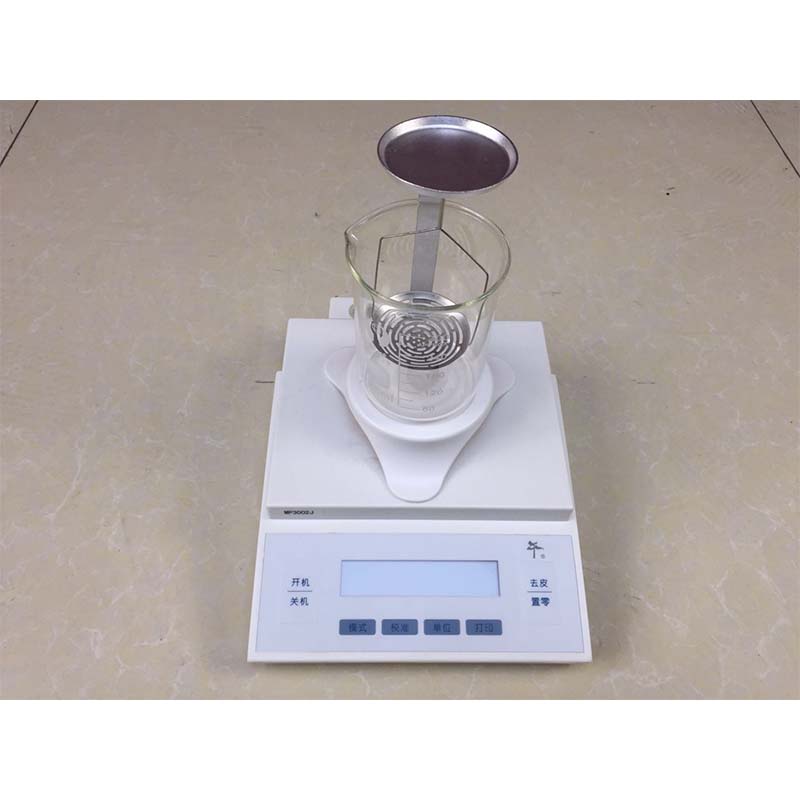

Wire and cable testing machines are specialized equipment designed to evaluate the performance, quality, and safety of electrical wires and cables. These machines subject wires and cables to various tests, including electrical resistance, tensile strength, insulation resistance, and more, to ensure they meet industry standards. With a robust testing process, manufacturers can detect potential issues early on, resulting in safer products and minimizing the risk of catastrophic failures.

The Role of Standards and Regulations

China, as one of the largest producers of wires and cables in the world, has implemented strict regulations and standards to ensure the quality of its products. These regulations are often aligned with international standards, such as those set by the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Testing machines play a vital role in helping manufacturers comply with these standards, thereby enhancing the credibility of their products in both domestic and international markets.

Types of Tests Conducted

Wire and cable testing machines conduct a variety of tests that assess different properties of the materials. Some of the most common types of testing include

1. Electrical Resistance Testing This test measures the resistance of the wire to the flow of electricity. High resistance can indicate potential problems such as poor connections or damaged insulation.

2. Insulation Resistance Testing Insulation is crucial for preventing short circuits. This test ensures that the insulation is intact and capable of protecting against leakage currents.

china wire and cable testing machine

3. Tensile Testing This evaluates the strength of the wire or cable under stress. It’s essential for understanding how the product will perform in real-life applications.

4. Temperature Cycling This test exposes wires and cables to extreme temperature changes to ensure they can withstand environmental stress.

5. Flame Resistance Testing With safety being paramount, this test evaluates how cables react to fire and whether they can slow down or prevent the spread of flames.

The Technological Advancements in Testing Machines

Recent technological advancements have transformed wire and cable testing machines into more efficient and accurate tools. Modern machines now feature enhanced sensors, automated data collection, and smart analytics. These innovations reduce human error, increase testing throughput, and enable real-time monitoring of test results. The integration of IoT (Internet of Things) capabilities allows manufacturers to track and analyze quality metrics over time, facilitating continuous improvement processes.

The Economic Impact on the Industry

The wire and cable industry is a vital segment of China's economy, contributing significantly to its manufacturing output. The investment in high-quality testing machines not only ensures compliance with regulations but also fosters consumer trust. Manufacturers that prioritize quality control are more likely to see an increase in demand for their products, both domestically and internationally. Moreover, by reducing the incidence of product failures and recalls, companies can save substantial costs associated with warranty claims and damage to their reputation.

Conclusion

Wire and cable testing machines are indispensable tools in the manufacturing landscape of China. As the industry continues to evolve, the emphasis on quality, safety, and reliability remains steadfast. By investing in advanced testing technologies, manufacturers are not only enhancing their operational processes but also contributing to a safer environment for consumers. The commitment to excellence in wire and cable production will undoubtedly propel China further into the global market, reinforcing its status as a leader in the electrical manufacturing sector. In an age where technology and safety go hand in hand, the role of wire and cable testing cannot be overstated.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy