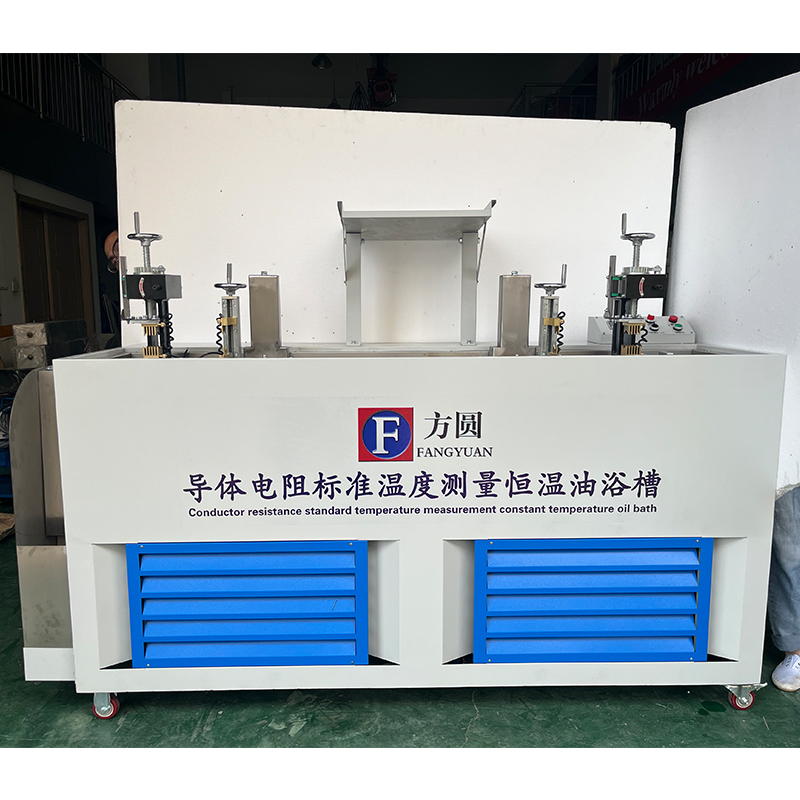

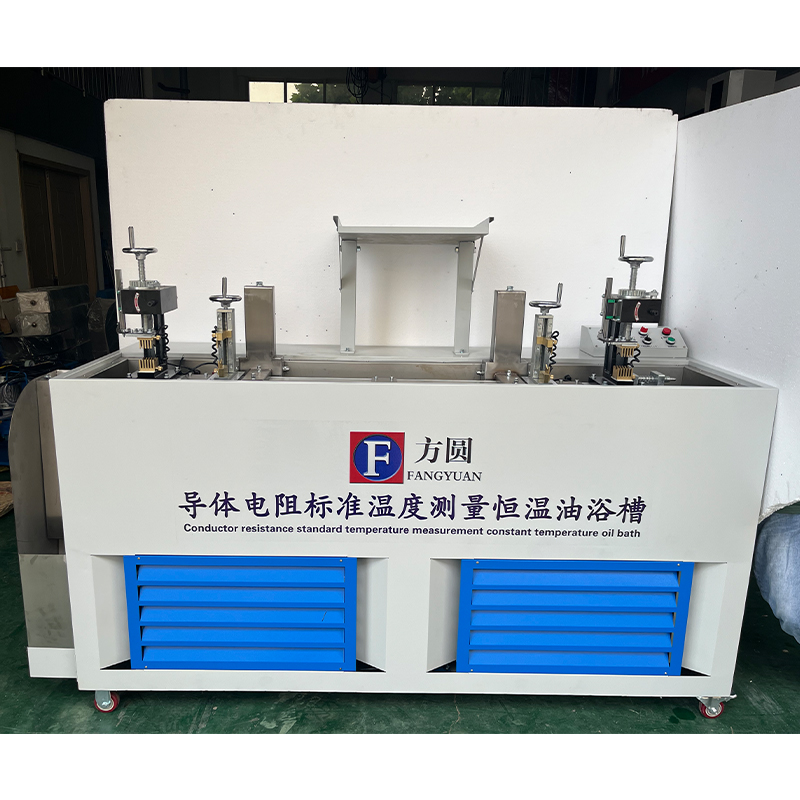

HWDQ-20TL Conductor Resistance Standard: Precision Temperature Oil Bath

Industry Trends & Market Relevance

The global push for greater reliability and accuracy in cable and conductor manufacturing has fueled a sharp rise in precision temperature measurement and calibration devices. According to Market Research Future, the oil bath calibration equipment market is expected to grow at a CAGR of 4.8% (2024-2029), driven by stricter quality standards (e.g., IEC 60502, ASTM B193), the grid modernization wave, and energy sector digitalization.

In this landscape, HWDQ-20TL Conductor Resistance Standard Temperature Measurement Constant Temperature Oil Bath maintains a competitive edge with its superior accuracy, robust material construction, and compliance with international protocols such as ISO 17025 and ANSI/ASTM D445.

Technical Specifications Overview

| Parameter | Specification | Industry Standard |

|---|---|---|

| Model | HWDQ-20TL Conductor Resistance Standard Temperature Measurement Constant Temperature Oil Bath | — |

| Temperature range | 15 – 110°C (precision stability ±0.01°C) | ISO 17025 |

| Temperature uniformity | ±0.02°C | ASTM B193-02 |

| Bath volume | 20 L | IEC 60684-2 |

| Heating method | Stainless steel immersion heater with PT100 feedback | ANSI/ASTM D445 |

| Material | 304 Stainless Steel / High-durability glass insulation | RoHS/REACH compliant |

| Control mode | Digital PID microprocessor | ISO 9001:2015 |

| Display | 7" color TFT touch screen | IEC 61131-2 |

| Service life | > 50,000 hours of operation | — |

| Certifications | CE, ISO 17025, RoHS | — |

Manufacturing Process Flow

HWDQ-20TL Conductor Resistance Standard Temperature Measurement Constant Temperature Oil Bath Workflow & Key Nodes

- Raw Material Selection — Precision grade stainless steel (304) sheets are procured with mill certification in compliance with ISO 9001.

- Stainless Steel CNC Fabrication — Panels and bath enclosure precision-cut by 5-axis laser CNC for ±0.1 mm tolerance.

- High-Pressure Die Cast Heater Mounting — Immersion heater cast and embedded for maximum conductivity and uniformity.

- PTFE & Glass Insulation Fitting — Corrosion-resistant PTFE lining inserted, followed by transparent heat-resistant glass window installation.

- PID Controller Assembly — Mounting of digital PID and integrated touchscreen per IEC 61131-2 wiring standards.

- Leak & Thermal Uniformity Testing — Each tank is 100%-pressure tested and pass stringent uniformity calibration against NIST traceable thermometers.

- Final Cleaning & Packing — ISO-class cleanroom assembly, packaging with anti-corrosion treatment for global shipping.

Technical Advantages of HWDQ-20TL Over Peer Brands

| Feature | HWDQ-20TL | Peer Brand A | Peer Brand B |

|---|---|---|---|

| Temperature Range | 15–110°C | 25–100°C | Room temp–90°C |

| Minimum Stability | ±0.01°C | ±0.03°C | ±0.05°C |

| Heating Method | Intelligent PID/Immersion heater | Basic analog heater | PWM control |

| Tank Material | 304 Stainless Steel | Aluminum alloy | Standard steel |

| Digital Display | 7” TFT Touch | 3” LCD | No digital |

| Validity of Calibration | 3 Years | 1 year | 1 year |

| Certifications | CE, ISO 17025, RoHS | CE | — |

| Warranty | 24 months | 12 months | 6 months |

Visualization: Key Technical Indicator Distribution

Customizable Solutions — Tailored for Industry Needs

- Volume customization (10L, 20L, 30L & custom sizes per project demand)

- Temperature range extension up to 130° C for special applications (contact for feasibility)

- Material upgrades — Optional 316 SS, Teflon lining for corrosive environments (verified by UL)

- Automation control — SCADA remote interface, RS485 or Ethernet optional

- Integrated calibration ports — Quick connect for ISO 17025/IEC 17025-compliant thermometers

- Industry-specific designs — Pipework-integration for oil & gas, anti-static layers for semiconductor labs

Typical Application Scenarios

- National Metrology Labs: Standardizing resistance at controlled temperatures for reference-grade conductor calibration

- Power Cable Factories: Testing conductor resistance in high-volume production per IEC 60228, ensuring batch-to-batch uniformity

- Research Institutes: Thermophysical property experiments on conductor alloys, polymers under programmed profiles

- Petrochemical Facilities: Ex-proof setups for on-site viscosity and resistance measurements in ATEX zones

- Water Supply & Drainage (Municipal): Quality assurance of copper/aluminum busbars against corrosion and temperature-induced drift

Performance in Real-World Case Studies

[Case Study A: PowerGrid Asia, 2023] — The utility utilized HWDQ-20TL Conductor Resistance Standard Temperature Measurement Constant Temperature Oil Bath to recalibrate 350+ copper conductor samples monthly; certified report reproducibility improved by 23%, saving $18,000/year in retesting and rejected material costs.

[Case Study B: PetroLab EU, 2022] — For corrosion-prone aluminum wire, adoption of the system’s 304 stainless construction and PID stability allowed sub-0.012Ω accuracy at 80°C, passing annual FDIS/IEC surveillance audit with zero findings.

[Case Study C: MetroMetrology CN, 2022] — Integrated RS485 remote readout enabled seamless connection with LIMS, halving operator time and expediting ISO 17025 reporting by 3 days per cycle.

Authoritativeness: Certifications & Industry Accreditations

Client Feedback & Experience

— Chief Metrologist, Eastern Grid Laboratory [2023]

— Cable Quality Engineer, EU WireTech [2022]

FAQ: Professional Q&A about HWDQ-20TL

- Q1: What material is used for the primary tank construction?

- A1: The bath tank is made of 304 grade certified stainless steel, selected for corrosion resistance, mechanical integrity, and compliance with ASTM A240/A240M.

- Q2: What is the standard temperature range and can it be customized?

- A2: The standard operating range is 15°C to 110°C; custom solutions up to 130°C are available for special industrial applications upon request.

- Q3: Which industry calibration standards does HWDQ-20TL adhere to?

- A3: It is calibrated and tested under ISO 17025, IEC 60684-2, ASTM B193-02, and integrated CE/RoHS protocols.

- Q4: What type of control system does the bath utilize?

- A4: A digital PID (Proportional-Integral-Derivative) microprocessor controller, offering real-time, high-resolution thermal regulation and programmable testing cycles.

- Q5: How is temperature uniformity ensured within the oil medium?

- A5: Through multi-point PT100 feedback loops and high-power yet low-turbulence immersion heaters, uniformity is maintained at ±0.02°C even under full thermal load.

- Q6: What are the main installation and operational certifications?

- A6: Installation follows ISO 9001:2015 and IEC 61131-2 control panel and wiring specifications; all units are factory safety-checked under IEC and EN electrical safety test protocols.

- Q7: What is the product’s expected lifecycle and warranty?

- A7: Service life exceeds 50,000 hours of operation, and all units are provided with a 24-month international warranty; extended service plans are available.

Delivery, Warranty, & Support

Delivery Time: Standard configuration: 15-18 business days EXW, custom models: 23-28 business days. Global rapid shipping available.

Warranty: 24 months parts & labor; responsive remote and on-site technical support.

Calibration: Pre-dispatch ISO 17025 certificate with each unit; recalibration support every 3 years.

Customer Support: 24/7 engineering hotline, multilingual technical documentation, remote diagnosis upgrade service.

Contact our engineering team today for demo scheduling, purchase quotations, or more technical details on the HWDQ-20TL Conductor Resistance Standard Temperature Measurement Constant Temperature Oil Bath.

References & Industry Forum Citations

- Oil Bath Market Trend Report, MarketResearchFuture, 2023

- ISO/IEC 17025:2017 – General requirements for the competence of testing laboratories

- ASTM B193 – Standard Test Method for Resistivity of Electrical Conductor Materials

- International Cable Quality & Metrology Forums

- IEEE: Advances in Constant Temperature Bath Calibration

- Temperature Uniformity and Stability Evaluation in Modern Metrology Baths (Research Article, 2023)

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy