Innovative Manufacturing Techniques in Cable Water Bath Production Facilities for Enhanced Quality Control

The Cable Water Bath A Vital Component in Manufacturing

In the realm of industrial manufacturing, the cable production process requires precise control and management of temperature and environmental factors to ensure high-quality outputs. One of the key elements involved in this process is the cable water bath, a pivotal component used in many cable factories that directly influences the quality and performance of the final product. This article will explore the significance, operation, and advantages of cable water baths in modern manufacturing settings.

What is a Cable Water Bath?

A cable water bath is a specialized apparatus used in cable manufacturing to cool and stabilize the temperature of wires and cables after they have been subjected to processes such as extrusion or annealing. By immersing the cables in a water bath, manufacturers can achieve the necessary thermal properties, leading to improved physical attributes of the cables, such as flexibility, durability, and resistance to environmental factors.

How Does It Work?

The operation of a cable water bath is relatively straightforward yet highly effective. After the cable has been extruded, it typically emerges from the machine at high temperatures. The immediate immersion in a controlled water bath provides an efficient cooling medium that helps regulate the temperature of the cable uniformly.

Water baths can vary in design; some are simple containers filled with water, while others are equipped with advanced temperature control systems, ensuring that water remains at optimal thermal levels for quick and consistent cooling. The flow of water can also be adjusted, allowing for enhanced cooling rates based on the specific requirements of the cable being processed.

Advantages of Using Cable Water Baths

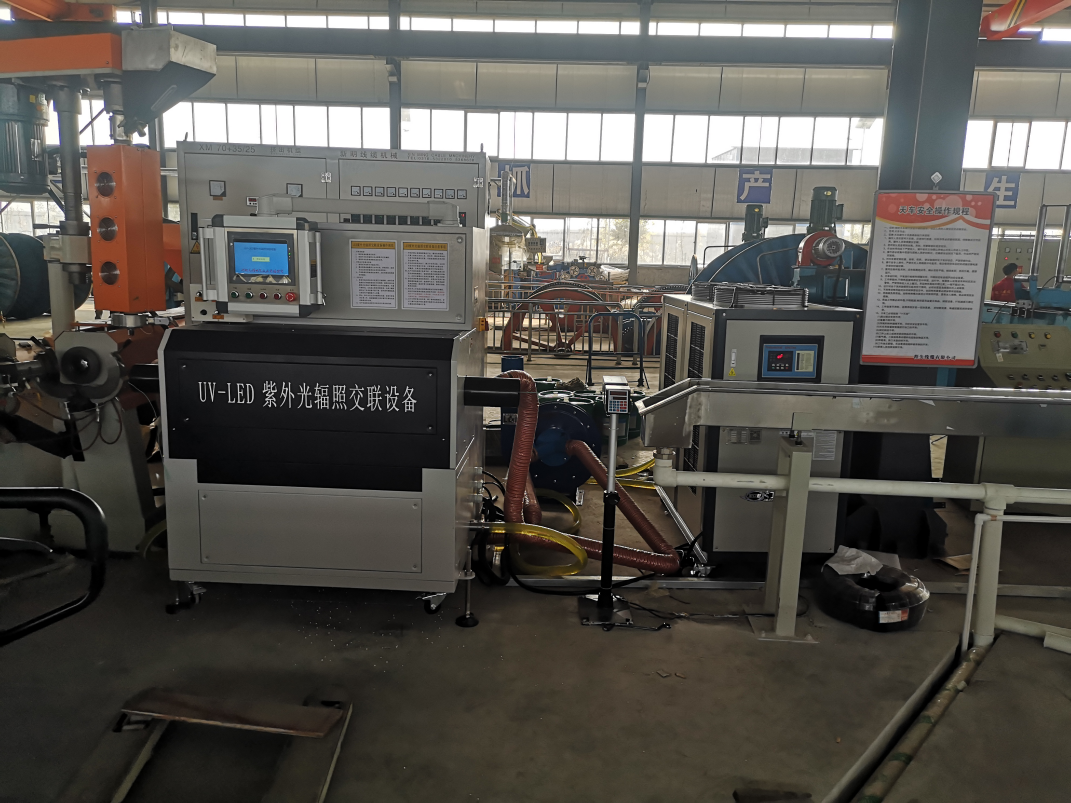

cable water bath factories

The integration of cable water baths into manufacturing processes offers several advantages

1. Enhanced Quality The cooling process facilitated by water baths helps in avoiding defects such as warping or uneven solidification. This leads to a more uniform product with improved electrical and mechanical properties.

2. Increased Efficiency By rapidly cooling the extruded cables, manufacturers can increase their output rates. Faster cooling times mean that the production cycle is shortened, leading to greater efficiency and productivity in the factory.

3. Better Control Water baths provide manufacturers with better control over the cooling process. By adjusting temperatures and water flow rates, manufacturers can tailor the cooling process to suit specific cable types and production needs.

4. Cost-Effectiveness While the initial investment in a cable water bath setup may be significant, the long-term benefits include reduced waste, fewer defective products, and enhanced operational efficiencies that contribute to cost savings.

5. Environmentally Sustainable Water is a natural and readily available cooling medium, making the cable water bath an environmentally friendly option compared to other cooling methods that may rely on chemicals or energy-intensive procedures.

Conclusion

In conclusion, cable water baths play a vital role in the manufacturing of high-quality cables. By providing an effective cooling mechanism, they ensure enhanced product quality, increased production efficiency, and better control over the manufacturing process. As the demand for cables grows across various industries—from telecommunications to power distribution—the importance of incorporating advanced technologies like cable water baths in production facilities cannot be overstated. Companies that invest in such technologies position themselves to meet market needs while maintaining product excellence and sustainability.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy