Laboratory Balance Utilization in Density Measurement within Manufacturing Facilities

The Role of Laboratory Balances in Density Measurement in a Factory Setting

In modern industrial settings, understanding the density of materials is crucial for quality control, product formulation, and compliance with industry standards. Laboratory balances play a vital role in accurately measuring the density of substances in factories. With the continuous push towards automation and precision in manufacturing processes, the significance of these instruments has never been greater.

Density, defined as mass per unit volume, is an important property that influences the functional characteristics of a product. For instance, in industries such as pharmaceuticals, food and beverage, and chemical manufacturing, the density of raw materials and finished products can affect everything from texture to stability and safety. Accurate density measurements ensure that products meet specified standards and perform as required.

Laboratory balances, designed for precise weighing, are essential tools in the density measurement process. They come in various types, including analytical balances and precision balances, each chosen according to the specific requirements of the operation. Analytical balances, for instance, offer high precision and are used for weighing small samples, which is crucial in industries where even the slightest variation in weight can lead to significant differences in density.

The process of determining density typically involves measuring the mass of a sample and its corresponding volume. Laboratory balances are employed to ascertain the mass, while the volume can be determined through methods such as displacement or geometrical calculations, depending on the state and form of the material. In some cases, specialized equipment like pycnometers may be used in conjunction with laboratory balances to enhance precision further.

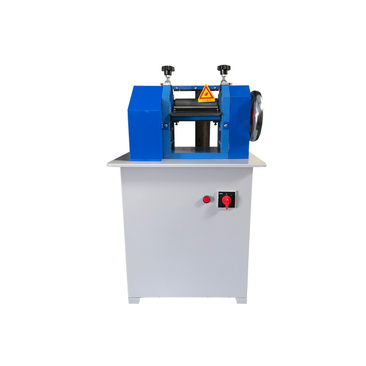

laboratory balance in density factory

One of the key advantages of using laboratory balances in density measurement is their ability to provide real-time data and minimize human error. In a factory environment where large volumes of material are processed, maintaining consistency in measurements is essential. Automated systems that integrate laboratory balances into the density measurement workflow can significantly improve efficiency and reliability. These systems can automate data collection and analysis, allowing for immediate feedback and adjustments in the manufacturing process.

Furthermore, the integration of laboratory balances with smart technologies enhances operational capabilities. Many modern balances come equipped with connectivity features, enabling them to communicate with other systems within the factory. This integration allows for seamless data sharing and management, contributing to a more streamlined workflow and improved decision-making processes.

It is also worth noting the importance of regular calibration and maintenance of laboratory balances. Inaccurate measurements due to improper calibration can lead to flawed density data, which can compromise product quality and safety. Factories must establish rigorous protocols for the upkeep of their laboratory balances to ensure ongoing accuracy and compliance with industry regulations.

In conclusion, laboratory balances are indispensable tools in the measurement of density within factory settings. Their precision, ability to automate processes, and integration with smart technologies play a significant role in maintaining high standards of quality control in manufacturing. By investing in reliable laboratory balances and ensuring their proper maintenance, factories can enhance their operational efficiency and produce products that not only meet but exceed industry expectations. As technology continues to advance, the role of laboratory balances in density measurement will likely expand, further solidifying their importance in the manufacturing landscape.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy