Universal Tensile Testing Equipment for Material Strength Evaluation and Analysis

Understanding Universal Tensile Testing Machines

A universal tensile testing machine is an essential piece of equipment used in the field of materials science, engineering, and quality control. These machines are designed to assess the mechanical properties of various materials by subjecting them to tensile stress until failure. The results obtained from these tests are crucial for understanding how materials behave under load, ensuring safety and reliability in various applications.

Key Components

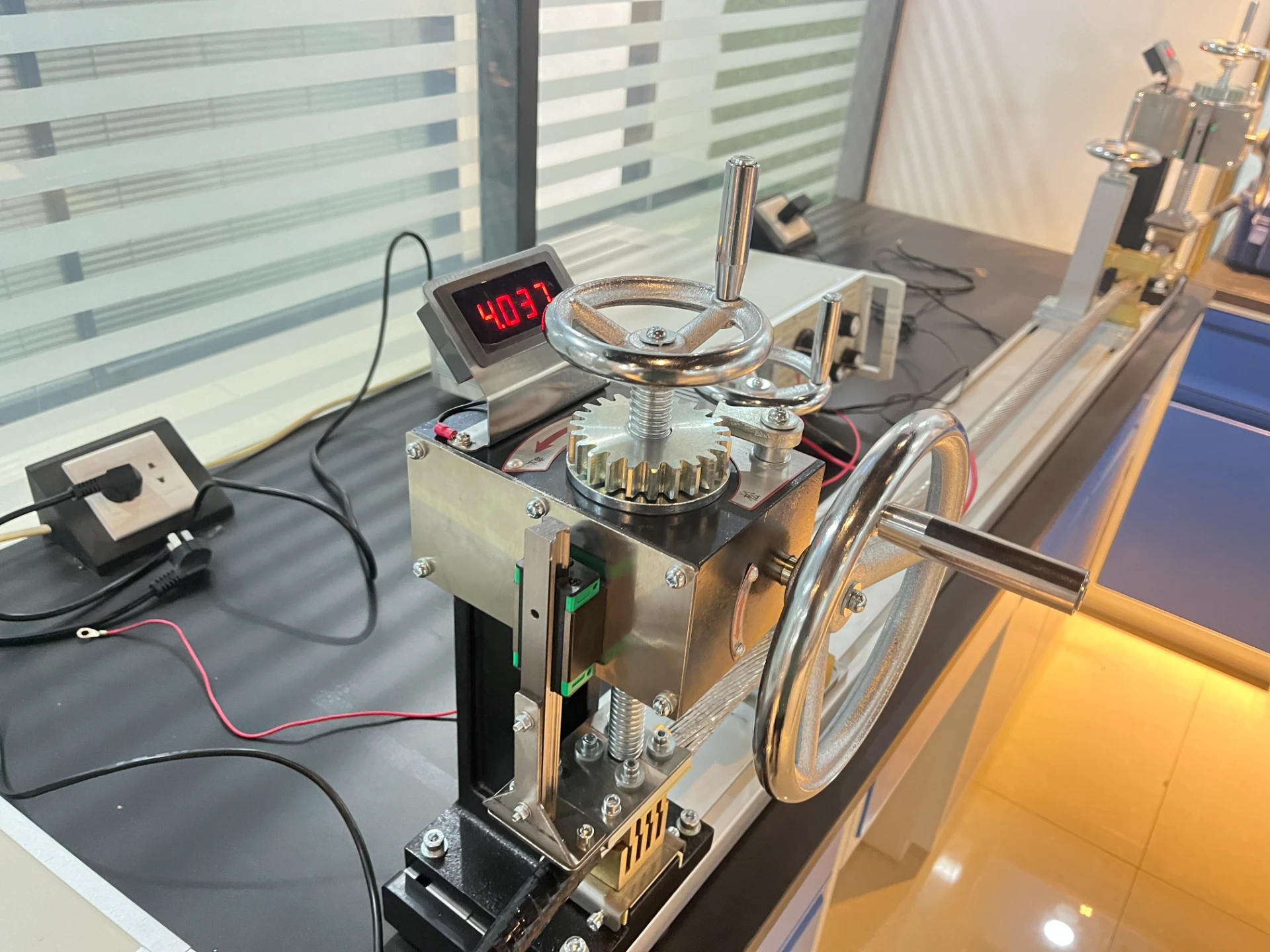

A universal tensile testing machine typically comprises several key components the frame, load cell, grips, crosshead, and an extensometer. The frame provides the structural integrity needed to withstand high forces applied during testing. The load cell is a critical component that measures the force exerted on the sample, converting the mechanical force into an electrical signal for accurate data collection.

Grips are used to hold the test specimen in place, ensuring that the load is evenly distributed and that the sample does not slip during the test. Different types of grips are available, depending on the material and shape of the specimen. The crosshead moves at a specified rate, allowing for precise control over the rate of extension. An extensometer measures the elongation of the sample, providing data on the material's deformation characteristics during the test.

Testing Procedures

The tensile testing process involves several steps. First, a specimen is prepared according to standardized dimensions, which may vary based on the type of material being tested. The specimen is then securely mounted in the grips of the testing machine. Once everything is set up, the machine begins applying tensile force at a constant rate until the specimen fractures.

universal tensile testing machine

During the test, the load and elongation data are recorded, allowing engineers and researchers to create a stress-strain curve, which is fundamental for understanding a material's mechanical properties. Key parameters derived from this curve include yield strength, ultimate tensile strength, elongation at break, and modulus of elasticity. These properties are essential for material selection in engineering design and manufacturing processes.

Applications

Universal tensile testing machines are widely used across various industries, including automotive, aerospace, construction, and consumer goods. In the automotive industry, for example, understanding the tensile properties of metals and polymers is vital for ensuring structural integrity and safety standards. Similarly, in construction, materials like steel and concrete must be tested to meet regulatory requirements and safety codes.

Moreover, these machines are invaluable in research settings, where scientists explore new materials and composites. The data generated from tensile testing can lead to innovations in material design and improvement of existing materials.

Conclusion

In summary, universal tensile testing machines are indispensable tools that provide critical insights into the mechanical properties of materials. By facilitating standardized testing procedures, these machines enable engineers and researchers to make informed decisions, ultimately contributing to safer and more efficient products. As technology advances, the capabilities and accuracy of these testing machines continue to improve, paving the way for even more sophisticated material testing methodologies in the future.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy