Factory for Testing Tensile Strength of Fabrics with Precision and Efficiency in Production

Understanding Fabric Tensile Strength Tester Factories

In the textile industry, the quality of fabric plays a crucial role in determining the final product's performance and durability. One of the key properties that is often assessed is the tensile strength of the fabric. This property indicates how much force a fabric can withstand while being stretched before it breaks. To accurately measure this important characteristic, manufacturers rely on fabric tensile strength testers, which are precision instruments designed for this specific purpose.

A fabric tensile strength tester factory specializes in the design and production of these testing machines. Establishing such a factory involves several crucial steps, including understanding the market demand, sourcing high-quality materials, and utilizing advanced technology to create user-friendly and reliable equipment.

Market Demand

The global demand for high-quality textiles continues to grow, driven by various sectors such as fashion, automotive, and home decor. As a result, manufacturers require accurate testing equipment to ensure their products meet industry standards. A fabric tensile strength tester factory must closely monitor these trends to produce equipment that meets evolving specifications. Moreover, compliance with international standards such as ISO 13934-1 highlights the necessity for factories to keep abreast of industry requirements.

Technology and Design

To produce reliable fabric tensile strength testers, factories must invest in cutting-edge technology and skilled labor. Modern testers often use computerized systems that allow for precise measurements and data logging. The design of these testers incorporates various features such as adjustable clamps, a digital display for ease of reading results, and software for comprehensive data analysis. The integration of user-friendly interfaces ensures that even non-technical personnel can operate the equipment effectively.

fabric tensile strength tester factory

Moreover, a significant focus is placed on durability and maintenance. Testers must be robust enough to handle frequent use without compromising accuracy. Factories achieve this by utilizing high-quality materials and employing rigorous quality control measures throughout the manufacturing process.

Customization and Client Needs

Different industries have different requirements when it comes to fabric testing. A reputable fabric tensile strength tester factory can offer customized solutions tailored to specific client needs. For instance, some clients may require testers that can accommodate a wide range of fabric types and thicknesses, while others may need machines capable of performing additional tests such as tear strength or elongation. By collaborating closely with clients, factories can develop specialized equipment that meets these diverse needs, enhancing customer satisfaction and loyalty.

Environmental Considerations

In today’s eco-conscious market, sustainability is becoming increasingly important in manufacturing processes. Fabrics made from organic materials or recycled fibers are gaining popularity, and it is essential that testing methods correspond to sustainable practices. A forward-thinking fabric tensile strength tester factory will likely implement environmentally friendly production processes, minimize waste, and ensure their machinery is energy-efficient. This not only appeals to a growing segment of eco-conscious consumers but also complies with strict environmental regulations.

Conclusion

In conclusion, fabric tensile strength tester factories play a vital role in the textile industry by providing essential equipment that ensures the durability and reliability of fabrics. By focusing on market demands, embracing modern technology, and offering customized solutions, these factories can meet the diverse needs of their clients. Furthermore, by integrating sustainable practices into their operations, they contribute positively to the environment while catering to a more environmentally aware consumer base. As the textile industry continues to evolve, the importance of such specialized factories will only increase, making them indispensable partners in the quest for quality assurance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

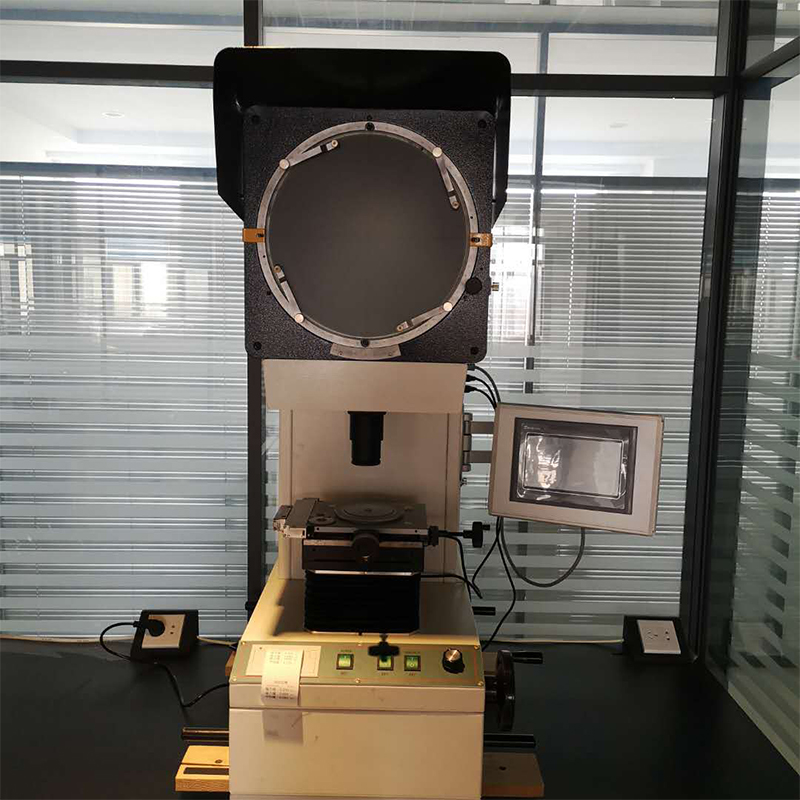

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy