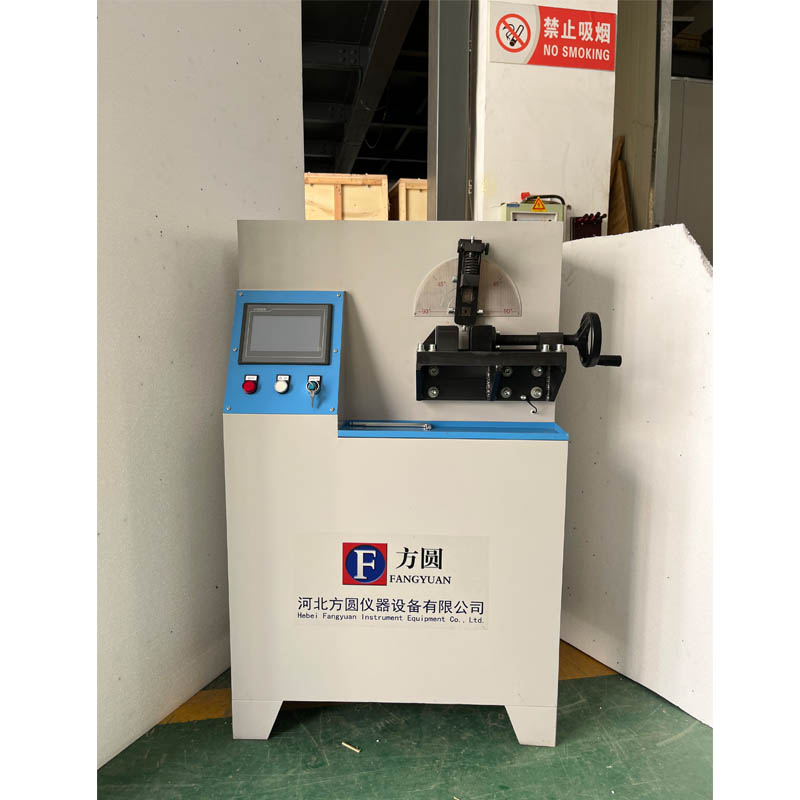

dc insulation resistance tester manufacturer

The Importance of DC Insulation Resistance Testers in Electrical Applications

In today’s technologically advanced landscape, ensuring the reliability and safety of electrical systems is paramount. One of the essential tools employed in this quest for safety and dependability is the DC insulation resistance tester. These testers play a critical role in assessing the insulation integrity of various electrical components, which is crucial in preventing power failures, equipment damage, and even fire hazards.

Understanding DC Insulation Resistance Testers

A DC insulation resistance tester essentially measures the resistance of insulating materials within electrical systems. It utilizes a direct current (DC) voltage to apply stress to the insulation, thereby evaluating its ability to withstand electrical leakage. By measuring the resistance, technicians can determine whether insulation is deteriorating or if it has become compromised over time.

The readings obtained from a DC insulation resistance tester are expressed in megohms (MΩ). Generally, a higher resistance value indicates better insulation quality. Conversely, low resistance values may indicate potential insulation failure or degradation, suggesting the need for further investigation or immediate remediation.

Applications Across Various Industries

DC insulation resistance testers are invaluable tools used across various industries, including electrical utilities, telecommunications, manufacturing, and transportation. In power generation and distribution, for example, they are used to inspect the insulation of transformers, motors, and generators. Any detected issues can be addressed proactively, minimizing the risk of downtime or unscheduled maintenance.

In telecommunications, the testing of cables and equipment is crucial to ensure system reliability. Insulation breakdown can lead to signal loss, which disrupts communication services. Similarly, in the manufacturing sector, regular testing of machinery can prevent costly repairs and ensure operational efficiency.

Benefits of Regular Testing

Conducting insulation resistance tests regularly offers numerous benefits. Firstly, it enhances the safety of electrical installations. By identifying potential issues early, companies can mitigate risks and avoid accidents. This proactive approach not only protects personnel but also safeguards valuable equipment.

dc insulation resistance tester manufacturer

Secondly, regular testing can lead to cost savings. By addressing insulation failures before they escalate into severe problems, businesses can avoid expensive repairs and extensive downtime. In a competitive environment where operational continuity is crucial, the financial implications of such savings cannot be overstated.

Moreover, routine insulation testing supports compliance with industry standards and regulations. Many regulatory bodies require specific insulation resistance values for safe operation. Failing to adhere to these standards can result in penalties and liability issues, making regular testing essential for compliance.

Choosing a Quality DC Insulation Resistance Tester Manufacturer

Selecting a reputable DC insulation resistance tester manufacturer is critical for ensuring the accuracy and reliability of testing equipment. When evaluating manufacturers, it is important to consider specific factors, such as

1. Product Quality The construction and material quality of the testers can significantly influence their durability and performance. Look for manufacturers that adhere to international standards and produce reliable instruments.

2. Range of Features Advanced features, such as data logging, connectivity options, and user-friendly interfaces, can enhance the usability of insulation testers.

3. Customer Support and Warranty Manufacturers that offer robust customer support and warranties demonstrate confidence in their products and prioritize customer satisfaction.

4. Reviews and Reputation Researching user reviews and the reputation of the manufacturer in the industry can provide insight into the reliability of their products.

Conclusion

In conclusion, DC insulation resistance testers are crucial instruments for maintaining the safety and efficiency of electrical systems. From preventing potential hazards to ensuring compliance with industry standards, the role of these testers cannot be overstated. By investing in quality testing equipment from reputable manufacturers, organizations can enhance their operational safety, optimize maintenance activities, and significantly prolong the lifespan of their electrical assets. In an era where electrical reliability is non-negotiable, ensuring that you have the right tools at your disposal is key to a successful and safe operation.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy