Supplier of Electronic Tensile Strength Testing Instruments and Equipment

Understanding Electronic Tensile Strength Testing Equipment A Guide for Suppliers

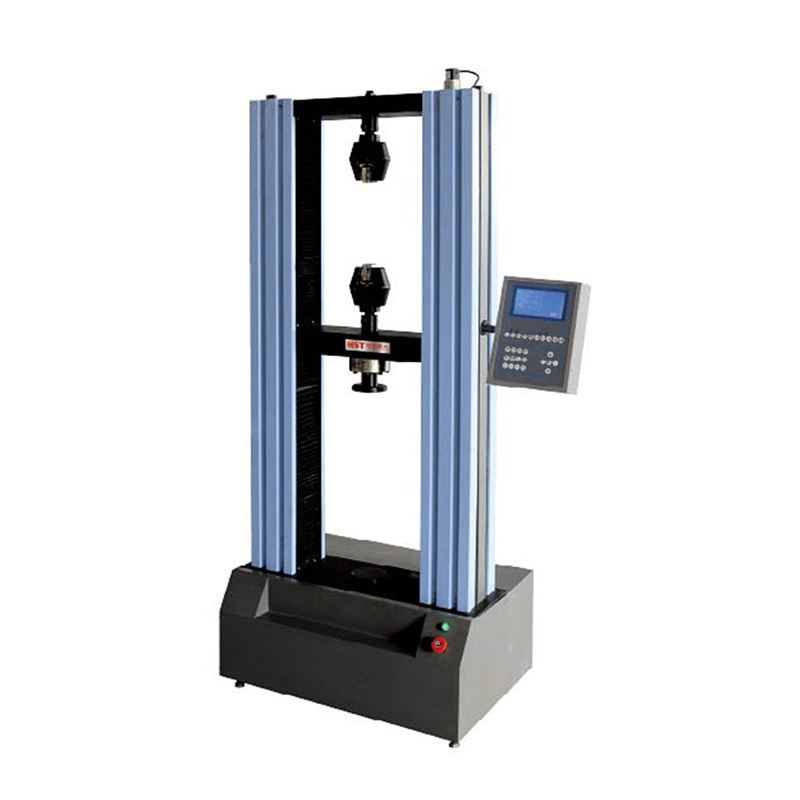

In the realm of material testing, electronic tensile strength testing equipment plays a crucial role in assessing the mechanical properties of materials. This specialized equipment is essential for industries ranging from construction and manufacturing to automotive and aerospace, where the integrity of materials directly affects safety and performance. As a supplier of electronic tensile strength testing equipment, it is imperative to understand the nuances of this technology and its applications.

What Is Electronic Tensile Strength Testing?

Tensile strength testing involves measuring the maximum amount of tensile (pulling) stress a material can withstand before failure. During a typical tensile test, a sample material is subjected to a controlled tension until it breaks. The primary objective is to determine how materials behave under tension, providing critical data such as yield strength, ultimate tensile strength, and elongation.

Electronic tensile strength testing equipment facilitates this process by utilizing advanced sensors and computer-based data acquisition systems. These systems ensure that measurements are precise and provide real-time data analysis. The integration of electronic components allows for greater accuracy and reproducibility than traditional mechanical testing methods.

Key Features of Electronic Tensile Strength Testing Equipment

1. Advanced Load Cells Modern electronic tensile testing machines are equipped with high-precision load cells that measure force exerted on the material with remarkable accuracy. This feature ensures reliable data even for the smallest samples.

2. Computer Interface Most electronic testing equipment comes with software that allows for easy data collection, storage, and analysis. Users can visualize stress-strain curves, which are essential for evaluating material performance.

electronic tensile strength testing equipment supplier

4. High-Speed Testing Electronic tensile testing machines can offer high-speed testing capabilities, allowing for rapid assessment without compromising the precision of results.

5. Versatility of Applications These machines can test a variety of materials, including metals, plastics, textiles, and composites. Such versatility makes them invaluable in quality control and research and development settings.

Importance for Suppliers

As a supplier of electronic tensile strength testing equipment, understanding the latest advancements in technology is crucial. Customers will look for machines that not only meet industry standards but also incorporate the latest innovations to enhance testing accuracy and efficiency.

Trends and Innovations

The market for tensile testing equipment continues to evolve, with trends toward increasing automation and digitalization. Suppliers should be aware of the growing importance of data analytics, where collected data can be further analyzed for quality assurance processes, enabling businesses to make informed decisions regarding material selection and product development.

Sustainability is also a significant consideration in today’s manufacturing landscape. Suppliers can differentiate themselves by offering solutions that minimize waste and energy consumption. Eco-friendly materials and processes are becoming increasingly important to clients who are striving to meet regulatory requirements and consumer demand for greener products.

Conclusion

Electronic tensile strength testing equipment is an essential tool for measuring the mechanical properties of materials in various industries. As a supplier, focusing on the latest technologies, offering versatile solutions, and understanding market trends can position your business as a leader in this niche sector. By providing high-quality, reliable, and innovative testing equipment, suppliers will not only meet customer needs but also contribute to advancements in material science, thereby playing a vital role in enhancing product safety and performance across industries.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy