Factory for Electronic Tensile Testers with Advanced Computer-Controlled Systems

Computer Control Electronic Tensile Tester Revolutionizing Material Testing in Factories

In the modern industrial landscape, where precision and reliability are paramount, the role of testing machinery has become increasingly critical. One such innovative piece of equipment that has significantly transformed the quality assurance process is the computer control electronic tensile tester. This advanced device is instrumental in evaluating the mechanical properties of materials, ensuring that they meet the required standards for various applications.

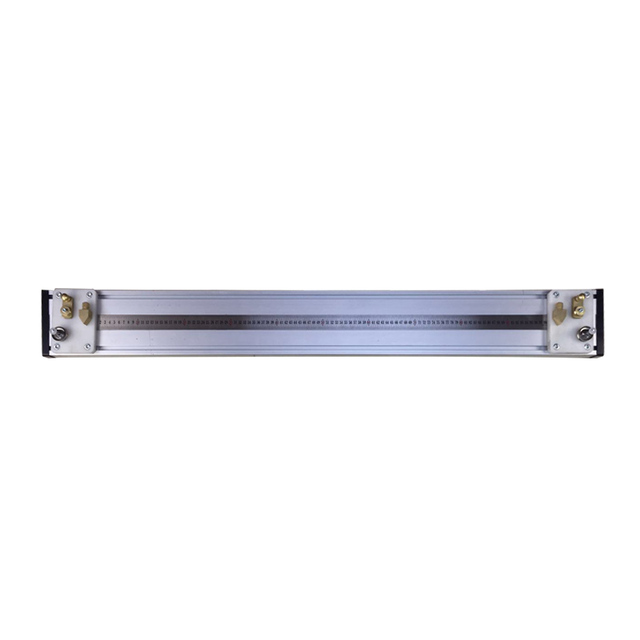

A computer control electronic tensile tester is designed to measure the tensile strength, elongation, and other mechanical properties of materials under stress. The operation of this device is anchored in advanced technology, allowing for highly accurate and repeatable results. Typically, it consists of a frame, a load cell for measuring force, grips to hold the specimen, and a computer system to monitor, control, and analyze the data produced during the test.

The integration of computer controls greatly enhances the functionality of electronic tensile testers. Unlike traditional mechanical testers, which may provide less precise results and require manual adjustments, computer-controlled models offer automated testing procedures. This not only increases efficiency but also reduces the margin for human error. Data acquisition and analysis can be performed instantly, providing real-time feedback during the testing process. The result is a streamlined workflow that enables factories to conduct extensive testing without unnecessary delays.

In a factory setting, the application of computer control electronic tensile testers is widespread. They are essential for industries such as construction, automotive, aerospace, and manufacturing, where material performance is crucial. These testers can evaluate various materials, including metals, plastics, textiles, and composites, making them versatile tools for quality control.

computer control electronic tensile tester factory

The benefits of using electronic tensile testers extend beyond mere accuracy. The data generated from these machines is invaluable for research and development activities. Engineers and scientists can analyze the stress-strain curves produced during testing to better understand material behavior under load. This information is crucial for designing products that can withstand specific conditions, thereby improving safety and performance standards.

Moreover, with the advent of Industry 4.0, the role of electronic tensile testers is evolving further. Many modern testers are equipped with smart technology, allowing them to connect with other devices and systems within the factory. This interconnectedness enables predictive maintenance, where the tester can alert operators about potential issues before they lead to failures. Such capabilities not only enhance the longevity of the equipment but also optimize the overall operational efficiency of the factory.

The implementation of computer control electronic tensile testers is also aligned with regulatory compliance. Many industries face stringent guidelines regarding material properties, and failing to meet these standards can result in costly recalls and legal ramifications. By utilizing electronic tensile testers, factories can ensure their materials and products adhere to these regulations, thereby safeguarding their reputation and financial stability.

In conclusion, the computer control electronic tensile tester represents a significant advancement in material testing technology. Its precision, efficiency, and data-driven approach make it an essential tool in modern factories. As industries continue to strive for higher quality standards and innovation, these testers will undoubtedly play a crucial role in achieving and maintaining the integrity of materials used across various sectors. By investing in such technology, factories not only enhance their productivity but also contribute to the advancement of industry-wide standards in quality assurance and safety.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy