Leading Manufacturers of Advanced Tensile Testing Machines for Quality Assurance in Material Testing

Understanding Tensile Tester Machine Factories

In the realm of materials science and engineering, tensile testing is a crucial procedure that enables the evaluation of a material's mechanical properties, particularly its strength and ductility. Tensile tester machines are essential tools in various industries, including construction, manufacturing, and plastics, as they provide quantitative data about a material's ability to withstand tension. This article explores the intricacies of tensile tester machine factories, their significance, and the technological advancements driving their evolution.

The Role of Tensile Tester Machines

Tensile tester machines are designed to apply a controlled tension to a specimen until it fails. The primary objective is to measure properties such as yield strength, ultimate tensile strength, elongation, and reduction of area. These parameters are vital for quality control and assurance in manufacturing processes, aiding engineers in selecting the right materials for specific applications.

The typical components of a tensile testing machine include a load cell for stress measurement, grips for holding the specimen, and a programmable control system that allows for precise application of tension. The data collected can lead to insights into how materials behave under different conditions, informing product development and safety standards.

The Importance of Quality in Manufacturing

For tensile tester machine factories, the quality of the machines produced is paramount. These factories must adhere to stringent industry standards and certifications, such as ISO 9001, to ensure that their machines provide accurate and reliable results. The manufacturing process includes the selection of high-grade materials, precision engineering, and rigorous testing of each machine before it leaves the factory floor.

Moreover, innovation is critical. Manufacturers are continuously seeking ways to enhance the performance and reliability of their machines. This involves integrating advanced technologies, such as computer numerical control (CNC) and automation, to improve efficiency and reduce human error. The use of modern software for data analysis further enhances the capability of tensile testers, allowing for more comprehensive and user-friendly results.

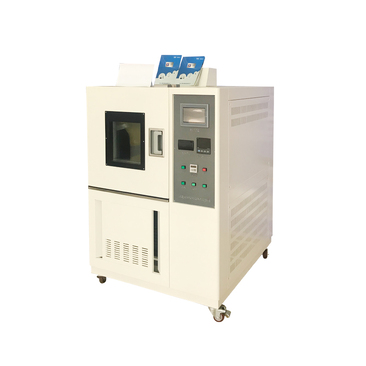

tensile tester machine factories

Trends Shaping the Industry

Several trends are currently influencing the tensile tester machine industry. One significant trend is the growing demand for automation. Factories are increasingly implementing automated systems to streamline operations, reduce labor costs, and improve precision. These systems enable continuous monitoring and adjustment of testing parameters, ensuring that results are consistent and accurate.

Additionally, the rise of smart technology has paved the way for the development of digital tensile testing machines. These machines offer real-time data analysis, remote monitoring, and connectivity features that allow engineers to access results from anywhere. Such advancements not only enhance the user experience but also provide valuable insights into material performance over time.

Challenges in the Market

Despite the advancements, tensile tester machine factories face several challenges. The global supply chain disruptions, driven by factors such as geopolitical tensions and pandemics, can affect the availability of essential components. Additionally, the industry must remain vigilant against competition from low-cost manufacturers, particularly in emerging markets.

To navigate these challenges, factories are focusing on innovation, customer service, and product customization. By understanding the specific needs of their clients and offering tailored solutions, manufacturers can maintain a competitive edge in a crowded market.

Conclusion

Tensile tester machine factories play a vital role in ensuring the integrity and performance of materials across various industries. As technology continues to advance, these factories must embrace innovation and adapt to changing market conditions. By prioritizing quality, automating processes, and leveraging smart technologies, they will not only enhance their production capabilities but also contribute to the advancement of materials science as a whole. The future of tensile testing is promising, and the factories that adapt to the evolving landscape will undoubtedly thrive in this essential sector.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy