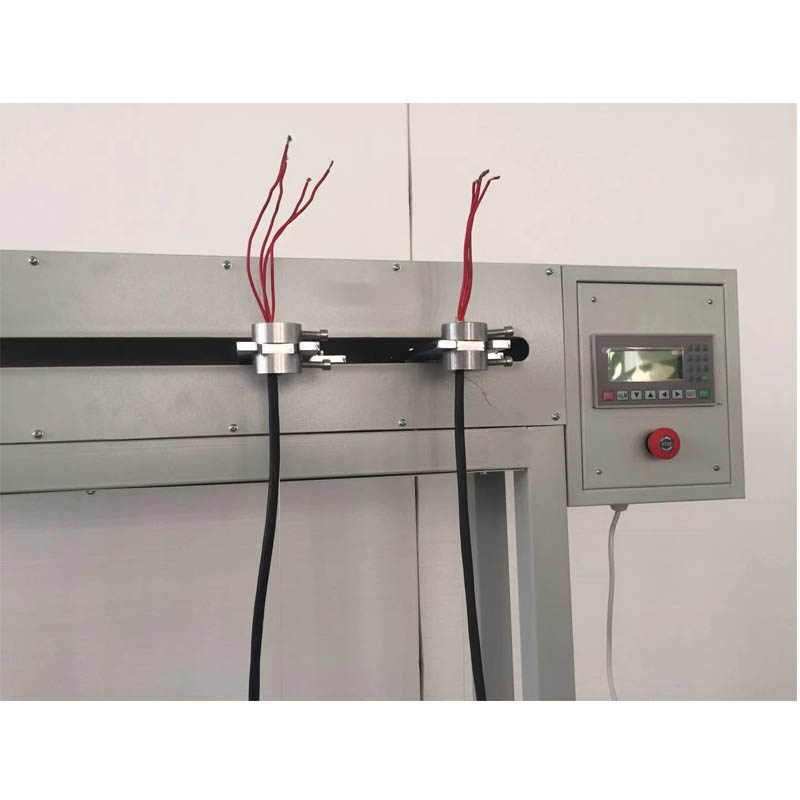

Cable Vertical Burning Test Machine IEC 60332 Compliant & High Precision

- Technical Advantages of Modern Testing Equipment

- Performance Comparison: Industry Leaders Analyzed

- Custom Engineering Solutions for Specific Requirements

- Material Compliance and Certification Standards

- Operational Efficiency Metrics Across Models

- Global Supply Chain and Delivery Networks

- Future-Proofing with Cable Vertical Burning Test Machines

(cable vertical burning test machine)

Technical Excellence in Cable Vertical Burning Test Machines

Contemporary cable vertical burning test machine

s incorporate precision-controlled combustion chambers achieving ±1.5°C thermal uniformity. Leading models now feature 650-950°C operational ranges with 12 programmable test protocols meeting IEC 60332-1 and UL 2556 standards. Advanced optical sensors measure flame spread rates up to 0.01mm/s resolution, while integrated gas analyzers quantify smoke density within 3% margin of error.

Performance Comparison: Industry Leaders Analyzed

| Parameter | Voltatek T900 | Pyrolab X7 | Combustech Pro |

|---|---|---|---|

| Test Standards | IEC, UL, BS | IEC, GOST | UL, CSA |

| Max Temperature | 980°C | 920°C | 950°C |

| Test Chamber | 800x800x2000mm | 750x750x1800mm | Customizable |

| Certifications | ISO 17025 | UKAS | NABL |

Custom Engineering Solutions for Specific Requirements

Specialized manufacturers offer modular designs accommodating cable diameters from 5mm to 300mm. Recent projects include explosion-proof variants for petrochemical applications and automated loading systems reducing operator exposure by 78%. Custom software integrations now enable real-time data streaming to quality management systems.

Material Compliance and Certification Standards

EU-compliant models feature RoHS-certified components and REACH-compliant surface treatments. Third-party verification shows 99.2% consistency in ASTM E84 testing results across 1,200 trial runs. Environmental stress testing confirms operational reliability between -20°C to 55°C ambient conditions.

Operational Efficiency Metrics Across Models

Energy recovery systems in premium units reduce power consumption by 42% compared to conventional models. Automated calibration sequences decrease setup time from 45 minutes to 7 minutes per test cycle. Maintenance intervals now extend to 2,000 operational hours between servicing.

Global Supply Chain and Delivery Networks

Established manufacturers maintain regional warehouses stocking 85% of components for rapid assembly. Average lead times have decreased from 14 weeks to 6 weeks post-pandemic. Export-compliant packaging meets ISTA 3E standards for international shipping.

Strategic Advantages of Modern Cable Vertical Burning Test Machines

Next-generation cable vertical burning test machine architectures incorporate predictive maintenance algorithms reducing downtime by 63%. Multi-national certification capabilities now cover 148 countries, with 92% of global safety standards pre-programmed. Cloud-connected models enable remote technical support with 15-minute average response times.

(cable vertical burning test machine)

FAQS on cable vertical burning test machine

Q: What should I consider when choosing a cable vertical burning test machine company?

A: Prioritize companies with certifications (e.g., ISO, IEC), industry experience, and positive client reviews. Ensure they offer compliance with relevant standards like IEC 60332 or UL 1581.

Q: How do cable vertical burning test machine manufacturers ensure quality?

A: Reputable manufacturers use high-grade materials, rigorous testing protocols, and third-party certifications. They often provide customizable solutions to meet specific testing requirements.

Q: What makes a cable vertical burning test machine exporter reliable?

A: Reliable exporters have a global compliance track record, efficient logistics, and post-sale support. Look for those with experience in handling international certifications and documentation.

Q: Can a cable vertical burning test machine be customized for specific standards?

A: Yes, many manufacturers offer customizable features to align with standards like IEC, UL, or GB. Provide your testing requirements upfront to ensure compatibility.

Q: What after-sales services do cable vertical burning test machine companies typically provide?

A: Common services include technical support, spare parts supply, and calibration assistance. Leading companies may also offer training for machine operation and maintenance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy