cable cutting machine manufacturer factories

The Evolution and Significance of Cable Cutting Machine Manufacturers

In an era marked by rapid technological advancement, the manufacturing industry is continually evolving to meet the demands of various sectors. One niche that has gained significant importance is the production of cable cutting machines. These machines are crucial for industries such as telecommunications, construction, and automotive, where precise and efficient cable management is essential. This article explores the evolution, significance, and the role of cable cutting machine manufacturers in the modern industrial landscape.

Cable cutting machines are designed to streamline the process of cutting cables to specific lengths and specifications. They eliminate the need for manual cutting, which can be time-consuming and prone to error. With the rise of automation, manufacturers have developed sophisticated machines capable of handling various cable types, including copper, fiber optic, and coaxial cables. These machines are equipped with advanced features like programmable logic controllers (PLCs), touch screen interfaces, and safety mechanisms that enhance efficiency and user safety.

As the telecommunications industry expands and the demand for faster internet connections grows, the need for high-quality cable cutting machines has surged. Manufacturers are now producing machines that can handle a diverse range of cable sizes and materials, catering to the specific needs of their clients. This flexibility has become a pivotal selling point for manufacturers, as businesses seek solutions that can adapt to their fluctuating requirements.

cable cutting machine manufacturer factories

The significance of cable cutting machine manufacturers goes beyond mere production; they play a critical role in ensuring the overall quality and reliability of cable-based products. By providing efficient machines that enhance precision in cable cutting, manufacturers contribute to reducing waste and increasing the longevity of the cables. In industries where safety and performance are paramount, such as the automotive and aerospace sectors, high-quality cables that have been cut and handled correctly can be the difference between success and failure.

Moreover, the growth of renewable energy sources and electric vehicles has further fueled the demand for cable cutting machines. As new technologies emerge, so do the requirements for innovative cable solutions. Manufacturers are responding to these challenges by investing in research and development to create cutting-edge machines that can accommodate the latest advancements in cable technology. This forward-thinking approach ensures that they remain competitive in an ever-evolving market.

The globalization of manufacturing also means that cable cutting machine manufacturers are not only catering to local markets but are also shipping their products worldwide. This international reach opens up new avenues for growth and collaboration. Manufacturers can share best practices, engage in cross-border partnerships, and tap into emerging markets, enhancing their product offerings and expanding their customer base.

In conclusion, cable cutting machine manufacturers play an essential role in the industrial landscape by providing the tools necessary for efficient cable management. Their evolution reflects the broader trends in automation and technological advancement, ensuring that industries can meet their operational needs effectively. As sectors continue to innovate and expand, these manufacturers will undoubtedly evolve alongside them, embracing new challenges and contributing to the seamless integration of cable solutions across various applications. For businesses seeking efficiency, precision, and reliability, partnering with reputable cable cutting machine manufacturers is a crucial step towards achieving operational excellence.

-

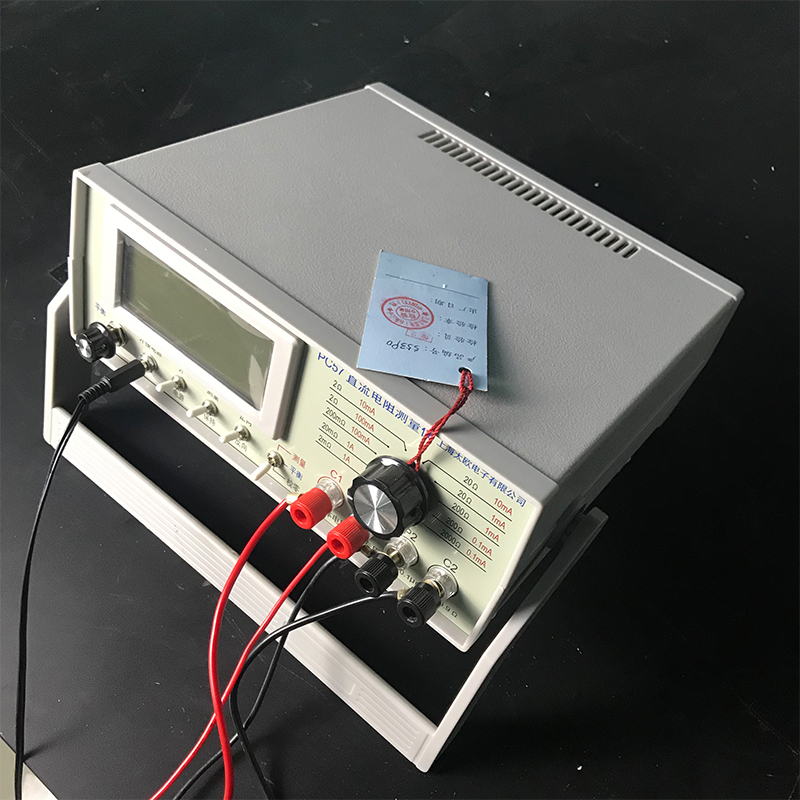

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy