50 ton tensile tester factories

The Role of 50 Ton Tensile Testers in Modern Manufacturing

In the realm of material science and engineering, tensile testing is a crucial procedure that assesses the strength and ductility of materials under tension. Among the various testing machines available, the 50 ton tensile tester stands out for its significant capability and versatility. This article delves into the importance of 50 ton tensile testers, the factors influencing their design and functionality, and the landscape of factories producing these machines.

Understanding Tensile Testing

Tensile testing involves stretching a material sample to determine how much force it can withstand before failing. This process provides invaluable data about the material’s physical properties, including its tensile strength, yield strength, elongation, and reduction in area. These properties are critical for manufacturers across diverse industries such as construction, automotive, aerospace, and electronics, where material performance directly impacts safety and efficacy.

Advantages of 50 Ton Tensile Testers

The 50 ton capacity of these testers allows for the evaluation of a wide range of materials, including metals, polymers, and composites. This capability is particularly beneficial for industries that require extensive testing of materials that undergo heavy loads and stress. A 50 ton tensile tester can efficiently handle samples with dimensions suitable for industrial applications, ensuring that manufacturers have accurate data available to inform design and safety standards.

Additionally, these machines are engineered to deliver precise results, thereby minimizing the risk of failure during application. This precision is vital for quality control, where manufacturers need to ensure that their raw materials meet specific strength criteria before they are utilized in production.

Key Features of 50 Ton Tensile Testers

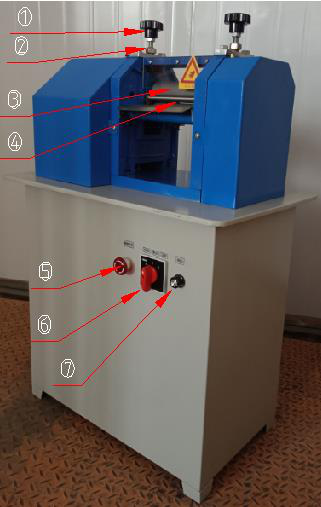

50 ton tensile tester factories

Modern 50 ton tensile testers are equipped with advanced features that enhance their functionality. Digital displays provide real-time data, allowing operators to monitor the testing process accurately. Many machines are also integrated with software for data analysis, enabling users to generate comprehensive reports and graphical representations of the results. This data can be crucial for compliance with industry standards and regulations.

Furthermore, safety is a primary concern in tensile testing. Robust designs, including features like overload protection and enclosed testing areas, help safeguard operators from the high forces involved in testing processes. These safety measures are essential in maintaining a secure working environment, especially in factories dealing with high-pressure testing scenarios.

The Global Market for Tensile Testers

As the demand for high-quality materials grows, so does the market for tensile testing machines. Factories around the globe are specializing in the production of tensile testers, including the 50 ton variant. These factories are often located in regions that have a strong manufacturing base and access to advanced technologies. Many manufacturers are now also focusing on automation and digitization, leading to the development of smart tensile testers that can monitor and report data autonomously.

In addition to new machinery, there is a growing market for refurbished tensile testers, which offers cost-effective solutions for smaller businesses. This trend allows companies to invest in reliable testing equipment without bearing the full cost of brand-new machines.

Conclusion

The 50 ton tensile tester plays an indispensable role in ensuring the integrity of materials used in various industries. With their remarkable capacity and accuracy, these machines help manufacturers uphold safety standards and improve product quality. As factories continue to innovate and enhance the design of tensile testing machines, the significance of tensile testing in modern manufacturing is set to rise, substantiating the critical nature of this testing process in the development of reliable materials. As technology advances, the future of tensile testing looks promising, with improved efficiency and data-driven insights paving the way for better manufacturing practices.

-

Unleashing the Potential of Digital Profile Projectors

NewsMay.22,2025

-

Smoke Density Test Machines for Fire Safety Assessment

NewsMay.22,2025

-

Revolutionizing Testing with Electronic Tensile Tester

NewsMay.22,2025

-

Innovations in Resistance Test Equipment

NewsMay.22,2025

-

Exploring High Performance Cable Cross Linking Equipment

NewsMay.22,2025

-

Advancements in Conductor Resistance Test Equipment

NewsMay.22,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy