calibrate insulation resistance tester factory

Calibrating an Insulation Resistance Tester A Comprehensive Guide

Insulation resistance testers are essential tools in the electrical field, used to measure the resistance of electrical insulation in various devices and installations. Proper calibration of these testers is crucial to ensure accurate measurements and maintain safety standards. This article will provide an overview of the calibration process and highlight the importance of ensuring that testing equipment is functioning correctly.

Why Calibration is Important

Calibration is the process of verifying the accuracy of an instrument by comparing its measurements with a known standard. For insulation resistance testers, calibration is vital because inaccurate readings can lead to undetected faults, equipment failure, and potentially hazardous situations. Regular calibration helps in identifying drift in measurement instruments and ensures compliance with industry standards.

Steps to Calibrate an Insulation Resistance Tester

1. Gather Necessary Equipment Before beginning the calibration process, gather all necessary equipment, including a reference insulation resistance standard, a multimeter, and any required calibration tools. Always use equipment that is traceable to national or international standards.

2. Prepare the Tester Turn off the insulation resistance tester and check for any physical damages or anomalies. Ensure that the tester's battery is sufficiently charged, as low power can affect measurements.

calibrate insulation resistance tester factory

3. Connect the Reference Standard Connect the reference insulation resistance standard to the insulation resistance tester. This standard should provide a stable and known resistance value.

4. Take Measurements Activate the insulation resistance tester and record the resistance measurements. Compare these readings with the known values of the reference standard. This step will reveal whether your insulation resistance tester provides accurate readings.

5. Adjustment and Documentation If discrepancies are found between the tester's readings and the reference standard, adjustments may be needed. Follow the manufacturer’s instructions to recalibrate the device. After calibration, document the results, the calibration date, and the technician’s details for future reference.

6. Regular Calibration Schedule Establish a routine for calibration based on usage frequency, environmental conditions, and manufacturer recommendations. Regular checks ensure reliability and longevity of the equipment.

Conclusion

The calibration of insulation resistance testers is not just a regulatory requirement; it is a critical practice to ensure safety and functionality in electrical systems. By making calibration a routine procedure, technicians can identify potential issues before they become significant problems, ultimately saving time and resources. Investing in proper calibration equipment and training ensures that you can rely on your insulation resistance tester to provide accurate and safe measurements in all your electrical testing needs.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

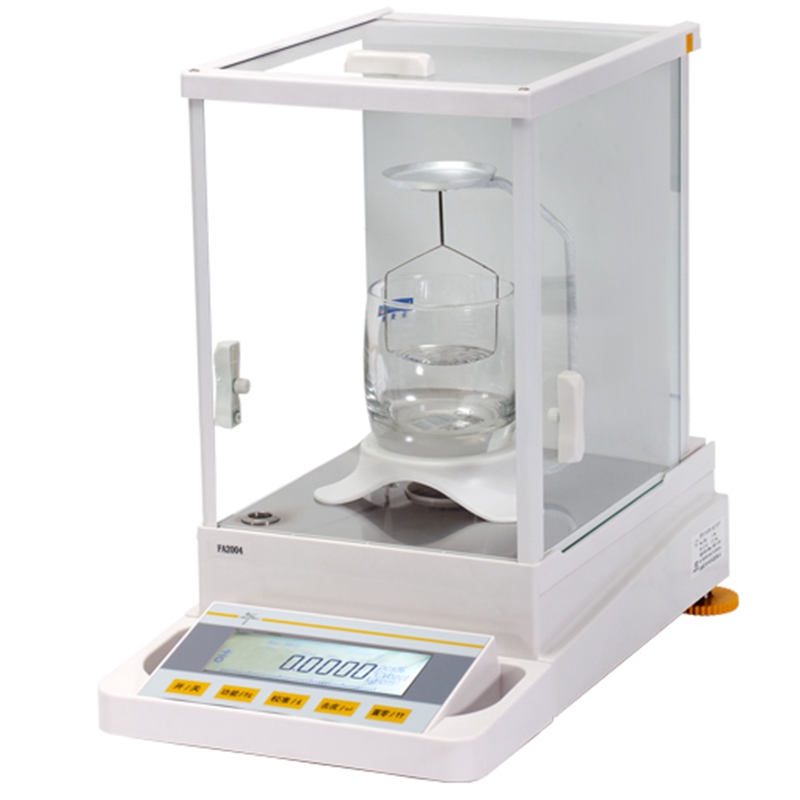

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy