computer control tensile strength tester manufacturers

The Role of Computer-Controlled Tensile Strength Testers in Modern Materials Testing

In the evolving world of material science, the demand for precise and reliable testing methods has led to significant advancements in tensile strength testing equipment. Among the latest innovations are computer-controlled tensile strength testers, which have revolutionized how manufacturers assess the mechanical properties of various materials. This article explores the importance of these testers, the leading manufacturers in the industry, and the future trends in tensile strength testing technology.

Tensile strength testing is crucial for evaluating the mechanical properties of materials, particularly their ability to withstand tension without failure. It plays a vital role in various industries, including construction, aerospace, automotive, and manufacturing. Traditional tensile testing methods often relied on manual operation and analog equipment, which could lead to human error and inconsistent data. However, with the advent of computer-controlled tensile strength testers, the accuracy, efficiency, and reliability of testing procedures have dramatically improved.

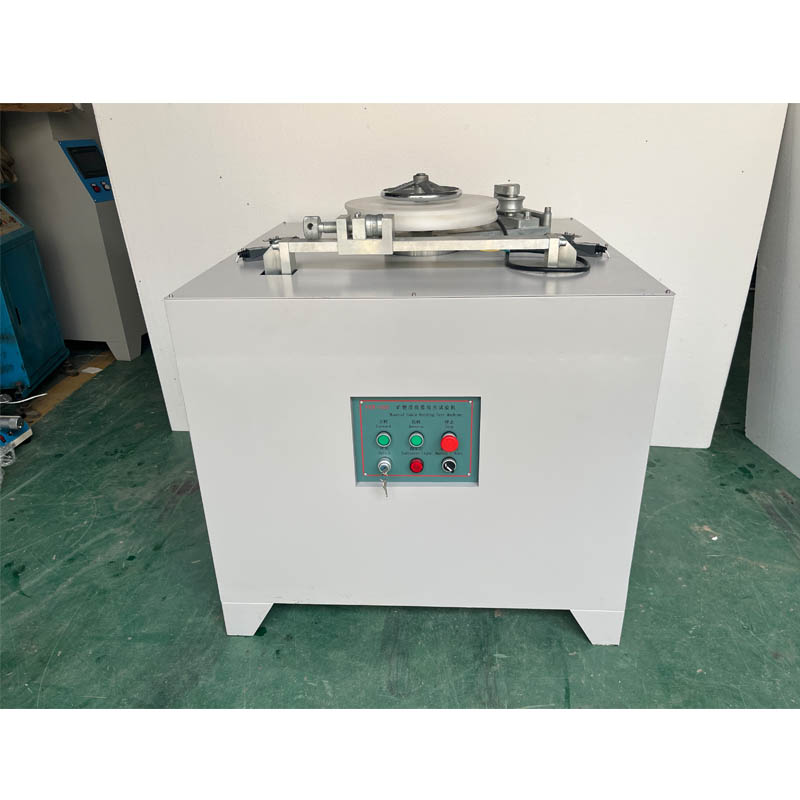

Computer-controlled tensile strength testers utilize advanced software and hardware to automate the testing process. These systems can apply precise loads, monitor elongation, and calculate critical parameters such as yield strength, ultimate tensile strength, and elongation at break. By minimizing the potential for human error, these testers ensure that the results are both consistent and repeatable, which is essential for quality control in manufacturing.

Several leading manufacturers specialize in producing high-quality computer-controlled tensile strength testers, catering to diverse industry needs. Companies such as Instron, ZwickRoell, and Shimadzu are recognized for their innovations and superior testing equipment. Each of these manufacturers offers a range of models with varying capacities and features to accommodate different materials and testing requirements. They also provide comprehensive support and training services, ensuring that customers can effectively utilize their equipment.

computer control tensile strength tester manufacturers

Additionally, many manufacturers integrate advanced technology into their testers, such as digital data acquisition systems and user-friendly interfaces. These enhancements allow for real-time monitoring of tests, automatic data logging, and sophisticated data analysis capabilities. As a result, engineers and quality control professionals can quickly interpret test results and make informed decisions regarding material selection and processing.

The growing need for materials with enhanced performance characteristics has led to a trend toward more sophisticated tensile strength testing methodologies. For example, the integration of machine learning and artificial intelligence technologies into testing systems is on the rise. These technologies can analyze large datasets generated during testing, revealing insights that were previously unattainable. This trend not only improves the understanding of material behavior but also aids in the development of new materials with optimized properties.

Moreover, sustainability considerations are increasingly influencing material testing practices. Manufacturers are focused on developing eco-friendly materials, which necessitates reliable testing to ensure adherence to performance standards. Computer-controlled tensile strength testers can be instrumental in evaluating the mechanical properties of these innovative materials, thus playing a critical role in advancing sustainable technology.

In conclusion, computer-controlled tensile strength testers are indispensable tools in the modern materials testing landscape. Their ability to deliver accurate, repeatable, and efficient results has made them a preferred choice for manufacturers across various industries. As technology continues to evolve, the future of tensile strength testing promises further integration of advanced analytical methods and a focus on sustainability. Companies that harness the power of these innovations stand to gain a competitive edge in a rapidly changing market, where material performance is paramount.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy