Resistance Evaluated Based on Customized Testing Methods for Enhanced Performance

Custom Tested Resistance Understanding its Importance in Modern Materials Science

In recent years, the concept of custom tested resistance has become pivotal in the field of materials science and engineering. This specialized approach involves customizing the testing processes for evaluating resistance in various materials, ensuring that they meet specific performance criteria and applications. As industries continuously evolve, so does the need for materials that exhibit superior properties, including enhanced durability, conductivity, and heat resistance.

At its core, custom tested resistance refers to the tailored methods applied to assess how materials respond to different forms of stress and environmental conditions. This concept is particularly relevant in areas such as electronics, construction, automotive, and aerospace sectors, where the reliability of materials can directly influence the safety and efficacy of the final product.

One of the primary factors driving the need for custom resistance testing is the rapid advancement of technology. With the introduction of new materials like composites, polymers, and nanomaterials, standard testing protocols often fall short. Custom testing allows researchers and engineers to evaluate these materials under the specific conditions they will face in real-world applications. For example, a material intended for aerospace use must be tested for its resistance to extreme temperatures, pressure variations, and other environmental stresses unique to that domain.

Another compelling reason for adopting custom tested resistance is the growing trend towards sustainability. As industries strive to reduce their carbon footprint and minimize waste, the demand for sustainable materials has surged. Custom testing ensures that these materials not only meet environmental standards but also perform effectively over time. This is particularly crucial for applications in renewable energy, where the longevity and efficiency of materials can have significant implications on overall energy production and resource conservation.

custom tested resistance

Furthermore, custom resistance testing plays a vital role in enhancing product innovation. By understanding how new materials behave under specific conditions, manufacturers can design products with improved performance characteristics, such as better thermal insulation or electromagnetic shielding. For instance, in the electronics sector, custom tested materials can lead to the development of gadgets that are lighter, more efficient, and more durable. Innovation in this domain often hinges on the ability to measure and analyze resistance meticulously, aligning material properties with cutting-edge technological demands.

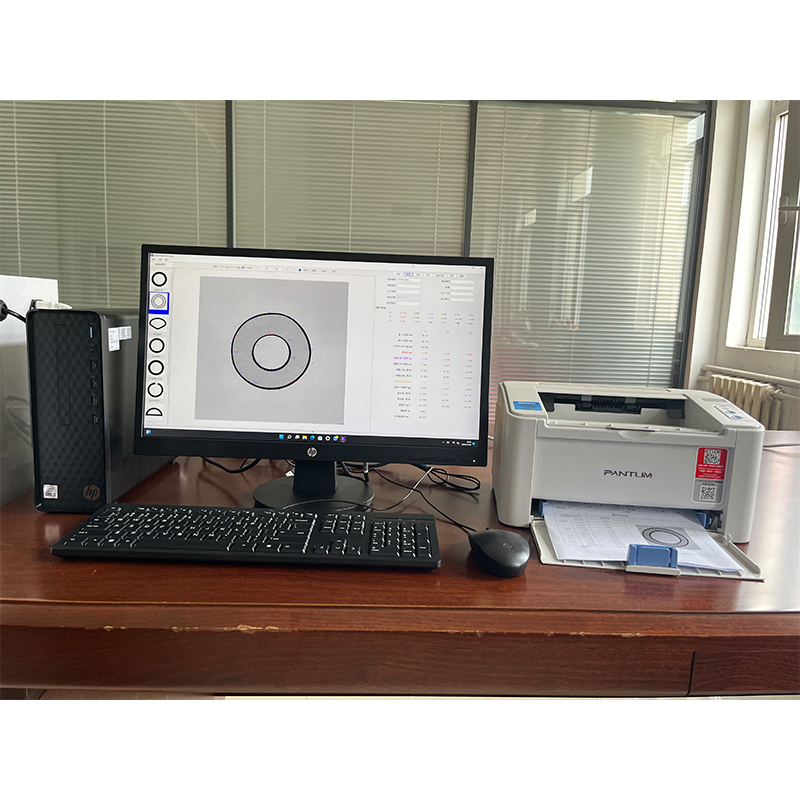

The process of custom tested resistance involves several methods, including mechanical testing, thermal analysis, and electrical measurements. Mechanical testing evaluates how materials respond to forces, while thermal analysis examines the effects of temperature variations. Electrical measurements assess how materials conduct or resist electric current, which is critical in applications ranging from circuit boards to power transmission lines. Each of these testing methods can be modified to adhere to the specific requirements of the material in question, ensuring that the testing process is not only rigorous but also relevant to the intended use.

Moreover, the importance of custom tested resistance cannot be overstated in the context of regulatory compliance. Industries often face stringent regulations regarding material safety and performance. Through custom testing, companies can provide solid evidence that their materials adhere to legal standards and are safe for public use. This not only enhances brand reputation but also mitigates the risk of product failure that could lead to catastrophic consequences.

In conclusion, custom tested resistance represents a crucial area of focus in materials science, influencing everything from product safety to sustainability and technological advancement. As industries continue to push the boundaries of innovation, the demand for specialized resistance testing will only grow. By embracing custom testing protocols, researchers and engineers can ensure that materials not only meet but exceed performance expectations, paving the way for a future defined by robust and resilient products. The journey of material evaluation is ever-evolving, and custom tested resistance stands at the forefront, promising a new era of material performance tailored to the complexities of modern applications.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy